Paper Laser Cutting

The world of art and craftsmanship has long been characterized by a delicate dance between tradition and innovation. At the intersection of these realms lies paper laser cutting, an avant-garde technique that harmonizes age-old paper artistry with cutting-edge laser technology.

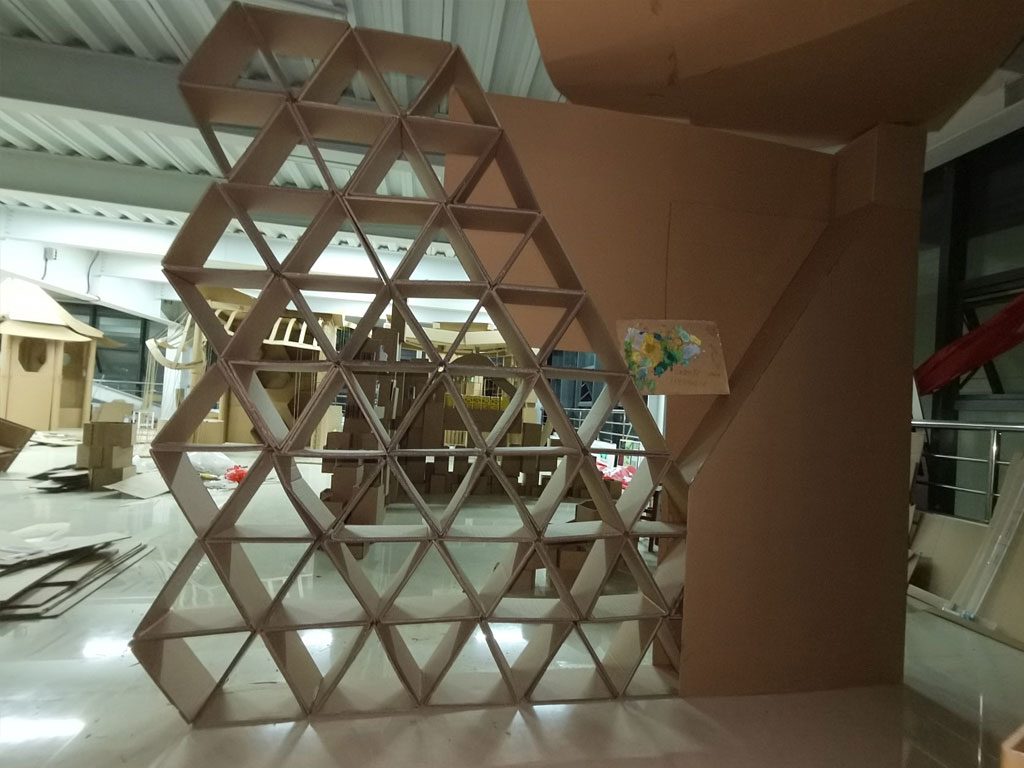

With its ability to transform paper into intricate lace-like designs, architectural models, and even high-fashion garments, paper laser cutting has captured the imagination of artists, designers, engineers, and educators alike.

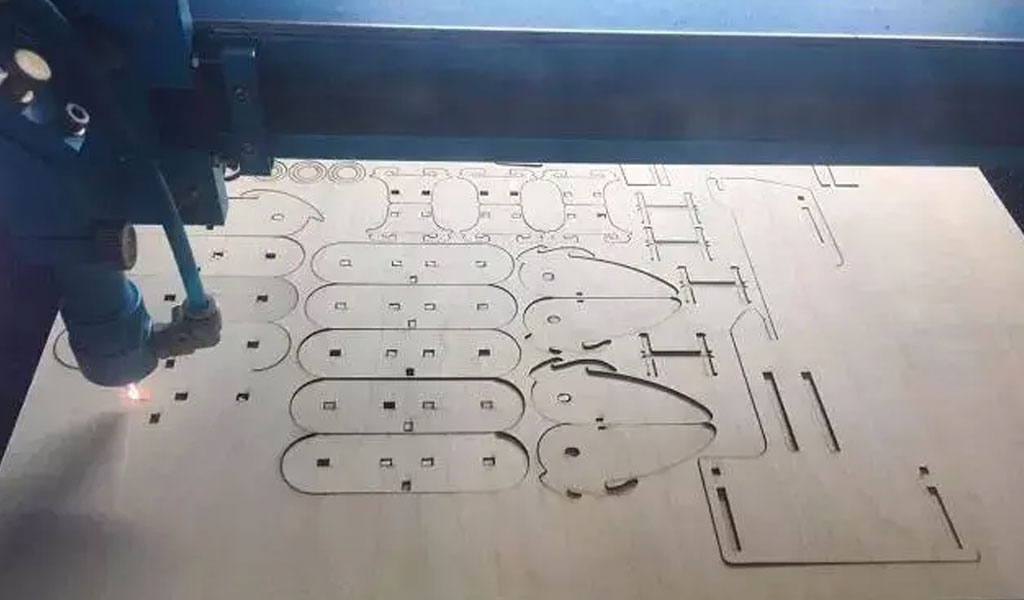

Recent decades have witnessed remarkable strides in the field of paper laser cutting technology. State-of-the-art laser systems offer unprecedented precision, enabling intricate designs with micron-level accuracy. Computer-controlled cutting techniques have revolutionized the art, allowing designers to translate their digital creations directly into physical paper forms. The integration of design software with laser cutters has democratized the process, making it accessible to artists and creators with varying levels of technical expertise.

What Is Paper Laser Cutting

Paper laser cutting is a modern technique that uses laser technology to precisely cut intricate designs, patterns, or shapes out of paper or paper-based materials. This process is widely used in various industries, including crafts, art, packaging, prototyping, and even commercial production.

Paper laser cutting offers numerous advantages, including high precision, intricate detailing, and the ability to reproduce complex designs consistently. However, it’s important to note that laser cutting can produce burnt edges on paper, especially if not properly adjusted, so choosing the right settings is crucial.

The essence of paper laser cutting lies in the interaction between laser beams and paper fibers. The physics behind this interaction is intricate, involving the conversion of laser energy into heat energy, which vaporizes or melts the paper at specific points. The precision of the process is influenced by factors such as laser power, cutting speed, focal length, and the paper’s composition. Different types of lasers, such as CO2 and fiber lasers, offer varying advantages in terms of cutting speed, accuracy, and material versatility.

Before attempting paper laser cutting, it’s recommended to familiarize yourself with the specific capabilities of your laser cutting machine and experiment with various settings to achieve the desired results while minimizing any potential damage to the paper.

Paper Laser Cut Service – Custom Laser Engraving Cardstock

In today’s competitive market, staying innovative and offering unique solutions is essential, and our cutting-edge technology and skilled team are poised to help you achieve just that.Our Paper Laser Cut Service opens doors to a realm of design opportunities that were previously limited by traditional cutting methods.

Paper laser cutting techniques embody the seamless interplay between imagination and technology. Each technique adds a layer of complexity, dimension, and functionality to the art of paper crafting.

Be-Cu Prototype offering vector cutting, raster engraving, kiss cutting, perforation, creasing, multi-layer cutting, etching, and embossing, creators gain access to a diverse toolbox of creative possibilities. Our advanced laser engraving technology ensures meticulous attention to detail, resulting in crisp and accurate engravings. From intricate patterns to intricate logos, we transform your designs into captivating, tactile experiences.

Traditional cutting methods can be time-consuming and costly, especially for intricate designs. Our laser cutting service streamlines the process, reducing production time and waste, ultimately leading to cost savings for you and your clients.Our advanced laser cutting technology ensures pinpoint accuracy, allowing intricate and complex designs to be translated onto paper with utmost precision. This accuracy enhances the quality of your projects and reduces the need for time-consuming post-processing.Whether you’re in the design, event planning, or creative industries, our Paper Laser Cut Service can elevate your projects to new heights. We invite you to visit our facilities, witness our technology in action, and discuss how we can collaborate to bring your vision to life.

Why Use Our Paper Laser Cutting Services

- No MOQ:One-off Iron laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom Paper laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the crafts, art, packaging, prototyping, and even commercial production and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

At Be-cu.com, we have dedicated experts that can handle all of your paper laser cutting services. We can assure the precision, quality, and affordability of your project components.Upload your CAD files today for one-on-one support service, and you will get a response(send your drawings to [email protected]) within 12 hours.

Paper Laser Engraving And Paper Cut Service

The delicate dance between creativity and technology has given rise to paper laser cutting, a fusion that has reshaped the possibilities of artistic expression and design. Through a variety of techniques, paper transforms from a flat surface into a medium of intricacy, depth, and functionality.

Vector Cutting

Raster Engraving

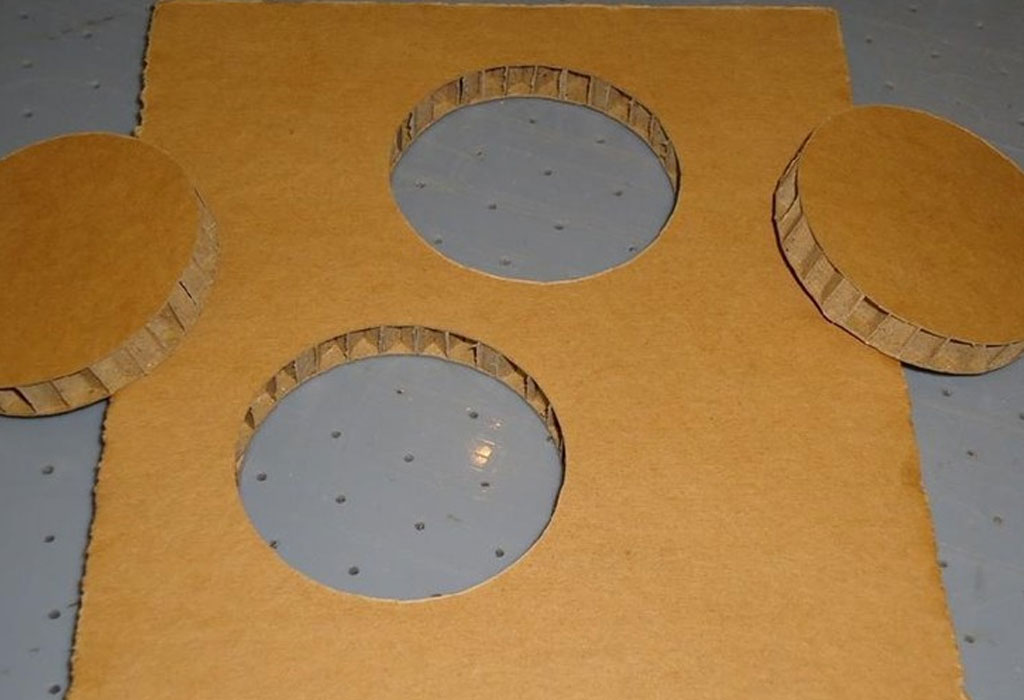

Kiss Cutting

Perforation

Etching and Embossing

Creasing and Scoring

Multi-Layer Cutting

Combining Techniques

Our Case Studies Gallery Of Paper Laser Cutting and Paper Laser Engraving

Paper laser cutting produces durable, end-use papercutting with a wide selection of paper materials and finishes that meet your specifications, for a variety of industries.Compared with traditional laser cutting companies, we have a large amount of precision machines, so we can do precision post-machining in house.Send your CAD files or inquiry to us, a fast, free online laser cutting quote of required paper model will be back. Get your Paper Laser Cut into fabrication in the shortest time.