Automotive Parts

- Material: Carbon Steel

- Custom Process: 3D Laser Cutting

- Other Process: Drilling And Cutting

- Casting surface roughness: Ra6.3-800

- Annual Volume: 100,000 per year

- Size: Custom

- Application: Custom

- Precision: +/-0.1mm

- Keyworld: Laser Cutting Steel

High-Quality Three-Dimensional Laser Cut and Welding Automotive Parts

The biggest feature of 3D laser cutting is its high flexibility, which is especially suitable for cutting small batches of 3D sheet metal materials. Its high flexibility is mainly reflected in two aspects:

- It has strong adaptability to materials. The laser cutting machine can basically cut any plate through CNC program;

- The processing path is controlled by the program. If the processing object changes, just modify the program. This is especially obvious when trimming and punching parts. Because trimming dies and punching dies are powerless for processing other different parts, and the cost of molds is high, currently 3D laser cutting has replaced trimming dies and punching dies. mold trend.

Generally speaking, the design and use of fixtures for three-dimensional machining are relatively complex, but no machining force is exerted on the processed plate during laser processing, which makes fixture production very simple. In addition, a laser device can achieve multiple functions if it is equipped with different hardware and software. In short, in actual production, three-dimensional laser cutting has obvious advantages in improving product quality and production efficiency, shortening product development cycles, reducing labor intensity, and saving raw materials.

Why Choose Our Three-Dimensional Laser Cut and Welding Automotive Parts Service?

- High cutting accuracy: the positioning accuracy of the laser cutting machine is 0.05 mm, and the repeat positioning accuracy is 0.03 mm.

- The cutting slit of the laser cutting machine is narrow: the laser beam is focused into a small light spot, so that the focus reaches a very high power density. The material is quickly heated to the vaporization level and evaporates to form holes. As the beam moves linearly relative to the material, the holes continuously form narrow slits, with the slit width generally being 0.10-0.20mm.

- The cutting surface of the laser cutting machine is smooth: there are no burrs on the cutting surface, and the surface roughness of the incision is generally controlled within Ra6.5.

- Laser cutting machine is fast: the cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than wire cutting.

- The cutting quality of the laser cutting machine is good: no-contact cutting, the trimming edge is very little affected by heat, there is basically no thermal deformation of the workpiece, and the sagging formed when the material is punched and sheared is completely avoided, and the cutting seam generally does not require secondary processing.

- No damage to the workpiece: The laser cutting head will not come into contact with the surface of the material, ensuring that the workpiece will not be scratched.

- Not affected by the shape of the workpiece: Laser processing is flexible, can process any graphics, and can cut pipes and other special-shaped materials.

- Suitable for the processing of large products: a single finished product no longer than 1500mm*3000mm can be cut at will. Mold manufacturing costs for large products are high. Laser processing does not require any mold manufacturing. Moreover, laser processing completely avoids sagging during material punching and shearing, which can greatly reduce the production cost of the enterprise and improve the quality of the product.

Contact Be Cu Now for your Custom Laser cutting, We are your best online Laser cutting services choice!

Specifications Of Three-Dimensional Laser Cut and Welding Automotive Parts

| Item Name | Sheet metal fabricating,Laser cutting service |

| Material | Aluminum,Carbon steel,Mild steel,Cold roll steel,Hot roll steel,Stainless steel,SECC,SGCC,SPCC,SPHC,Other metal |

| Thickness | 0.5mm-20mm,Depends on your products |

| High Precision | +/-0.1mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Zinc plating,Electroplating,etc |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

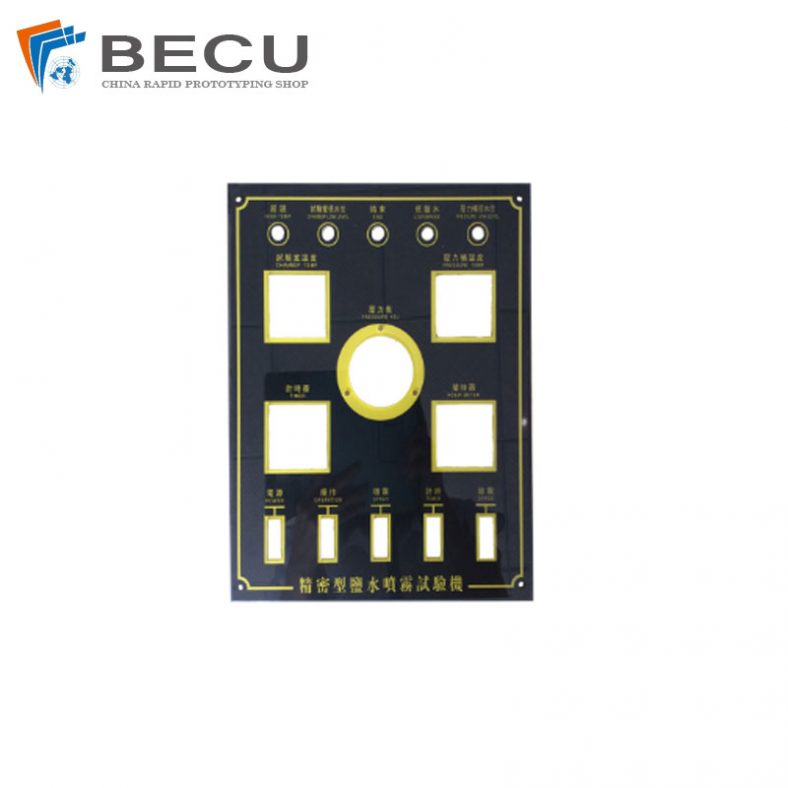

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

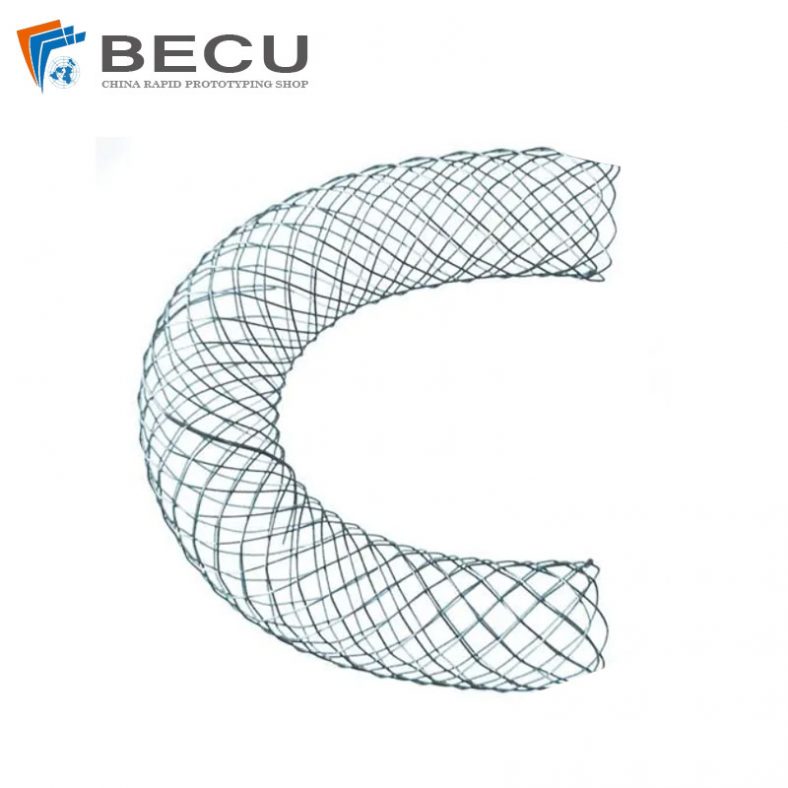

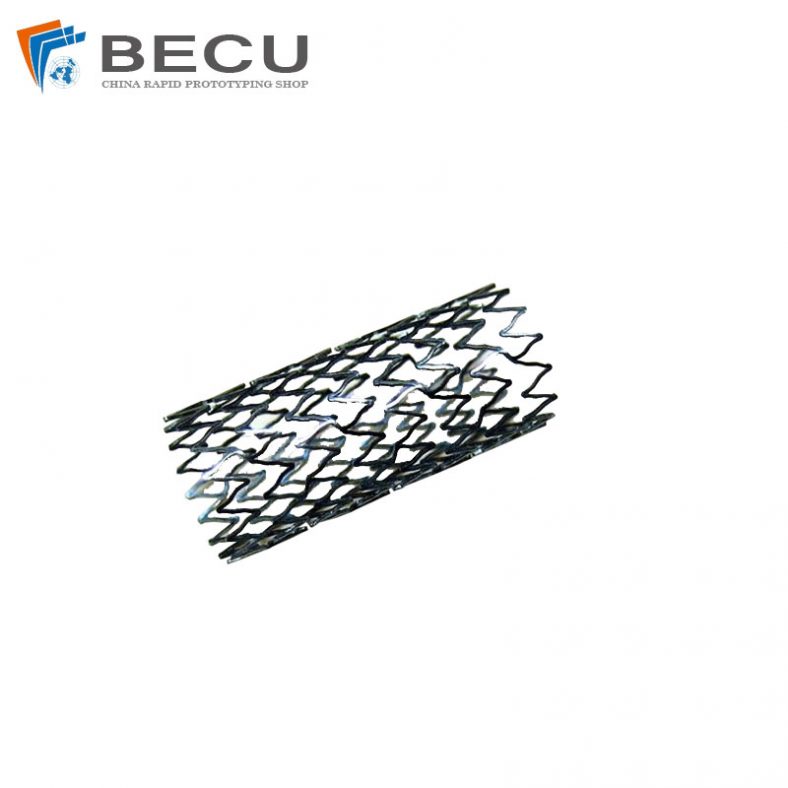

Laser Cut Nitinol Stent For Bile Duct

-

Stents For Carrying Valves And Venous Valve Replacement Devices

-

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings