11KG Machinery Parts

- Material: Gray Iron

- Casting Process:Sand Casting

- Casting precision grade: CT6-CT13 grade

- Casting surface roughness: Ra6.3-800

- Annual Volume: 100,000 per year

- Casting size: 20mm – 2000cm

- Leakage test requirement:Custom

- Casting Single Weight: 20g-1200kg

- Application:Machinery

- Utilizes coreless furnaces with 500 to 10,000 pound size and 50,000 gross pounds per shift melting capacities, AOD with 6,000 pounds rate and heat treat furnaces with up to 2,175 degrees temperature.

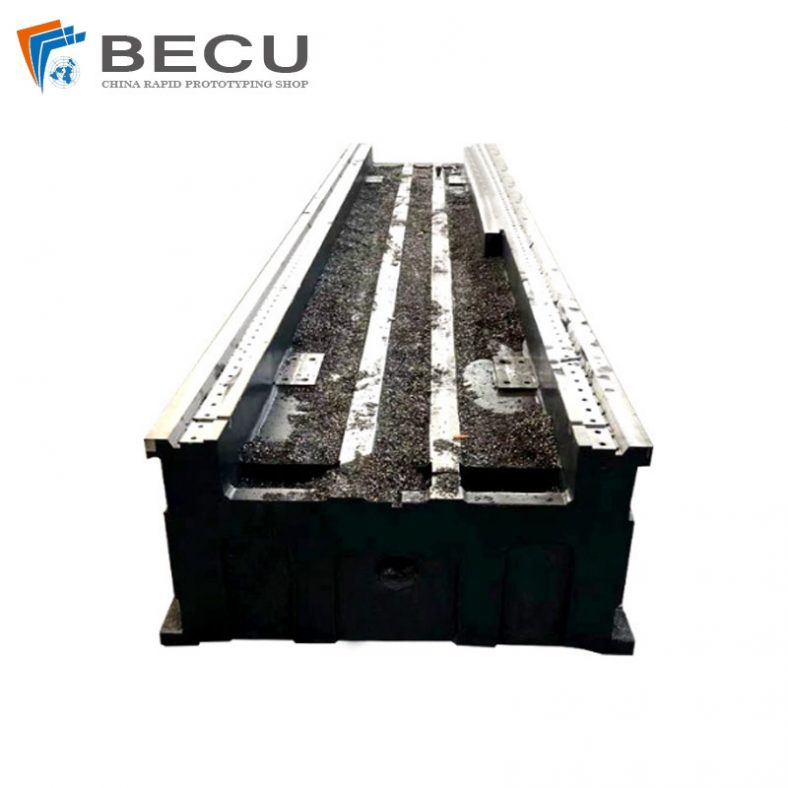

High-Quality Custom 11KG Gray Iron Sand Casting Machinery Parts

Custom manufacturer of medium sized and net shape horizontally parted 11KG Gray Iron Sand Casting Machinery Parts. Casting mold types include automatic molding and cope and drag. Ductile iron, ferritic, pearlitic and high silicon molybdenum ductile iron materials used. High silicon molybdenum castings are heat resistant. Available in dimensions up to 29 in. length, 29 in. width and 12 in. height with +/-0.8 mm tolerance. Additional services include finishing, inspection, prototyping and solidification modeling. Low to high volume production. Blanket orders accepted. Serves the agricultural, automotive, commercial, hydraulics, marine, military, mining, transportation and other industries. AutoCAD and SolidWorks® files accepted. Meets TS 16949 standards.

The Advantages Sand Casting Of 11KG Gray Iron Machinery Parts

- – Experience in casting for many years and served customers all around the world;

- – Good customer feedback and good reputation;

- – Competitive price and quality service;

- – Advanced machining and inspecting equipment;

- – Good quality control system;

- – Punctual delivery time.

- – Small order is welcome.

Sand Casting Processing Technology

- Resin sand steel casting process

- Casting Steel Produced by Modified Sodium Silicate Sand

- Water glass precision steel casting process

- Silica Sol Precision steel Casting process

The Production Equipment Of Sand Casting

- Be-cu Company has many years’ experience in casting industry.

- We have 96 workers for sand casting, 3 engineers and 6 quality inspectors. We are mainly engaged in ductile iron casting ( materials: 400-18, 400-15, 450-10, 450-12, 500-7, 600-7, 700-2, 800-2) and gray iron casting ( materials: HT150, HT200, HT250, HT300) , and the weight is between 0.5kg to 100kg ( for 100kg+, we have out source).

- Our factory has installed dust removing equipment and our products are environmental protection.

- Our products are totally for export and mainly export to Europe and America, therefore, we know the technical standard of Europe and America very well.

Why Choose Our Sand Casting Service?

1.Rich experience and resources of various manufactures

Our foreign trade sales team members have many years working experience.Our company has enormous resources of various manufacturers and distributors.And we can meet customers’ various needs in quality,quantity,price and delivery time etc.

2.Excellent service before purchasing

According to clients’ circumstances, we will recommend most suitable parts for them.Our company haenormous resources of various manufacturers and distributors.Professional service and positive feedback.

3.Competitive price and guaranteed quality

Competitive and reasonable price to help customers to win markets, reliable supplier and stable quality guarantee.

Specifications of 11KG Gray Iron Sand Casting Machinery Parts

| Available product name | Sprocket, gear, flange,gear box,valve, Roller, pulley,casting,forging,stamping,injection parts, Mchining parts, bearing house, worm gear and worm shaft , spline shaft/house , wheel hub, Mould design and other harware products |

| Material | Stainless steel, Metal, Aluminum&alloy, Carbon steel,Iron,Brass,plastic,zinc&alloy… |

| Production Process | Precision casting, sand casting,die casting,forging ,welding,gravity casting,lost wax casting,investment casting,stamping,CNC machining,injection… |

| Surface Treatment | Sand blasting,baking paint,chorme/zinc plating,spray paint,spray coating,oxygenation, polishing, electroplating, grind,oil blooming,blacking, Knurl, E-coat,deburring…… |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Green sand、Furan Resin Sand、Cold Harden Resin Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless steel, Carbon steel, Aluminum, Brass, Bronze,Custom By Be-Cu COM |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Sand Casting Company

Sand casting, also known as sand molded casting, is a process that uses non-reusable sand molds to form metal castings. This is a common production method for a wide range of metal parts from a few ounces to a few tons. Sand casting is not only versatile in terms of its product size, but it can also make very complicated or detailed castings and can cast almost any metal alloy.BE-CU.COM provides superior quality sand casting parts and components to industries including automotive, transportation, mining, petrochemical, electrical, energy and others. We cast sand casting parts up to 10 metric tons. Materials can be aluminum alloy, ductile iron, brass alloy, gray iron etc. We offer high precision CNC machining and other secondary operations. We also offer rapid prototype services. Both low to high-production volume sand casting are welcome.

-

Ductile Cast Iron Large Gantry Machine Tool Bed Castings

-

Malleable Cast Iron Agricultural Machinery Support Seat

-

CNC Machining Cast Iron Explosion Proof Junction Base

-

CNC Machining Large V-belt Pulleys

-

Ingot Molds For Aluminum ASTM A27

-

Stainless Steel Bathroom Hardware Sand Castings By Gravity casting

-

2 KG Building Parts By Green Sand Casting

-

5.5KG Automobile Fence Precision Parts By Green Sand Casting