Laser Cutting For Plastic

Laser cutting is a non-contact subtractive manufacturing process that utilizes a highly focused laser beam to precisely cut through materials. When it comes to plastic, this technology offers unparalleled precision, allowing for intricate and complex designs to be realized with minimal material waste.Plastic, with its diverse range of types and properties, presents a unique set of challenges and opportunities for laser cutting. Common plastics suitable for laser cutting include acrylic, polycarbonate, PET, and ABS. Each type of plastic responds differently to the laser cutting process, necessitating a nuanced approach based on the material’s characteristics.

Laser cutting for plastic stands at the forefront of modern manufacturing, revolutionizing the way we approach design and fabrication. As technology continues to advance, the applications and benefits of laser cutting will likely expand, ushering in a new era of precision and efficiency in plastic manufacturing processes. Whether in prototyping, signage, medical devices, or electronics, laser cutting has proven itself as a versatile and indispensable tool, shaping the future of plastic fabrication.

Plastic Laser Cut Service – Custom Laser Cutting Plastic Parts Company

At Be-Cu prototype, we offer laser cut services for different plastic materials.

Be-Cu.com

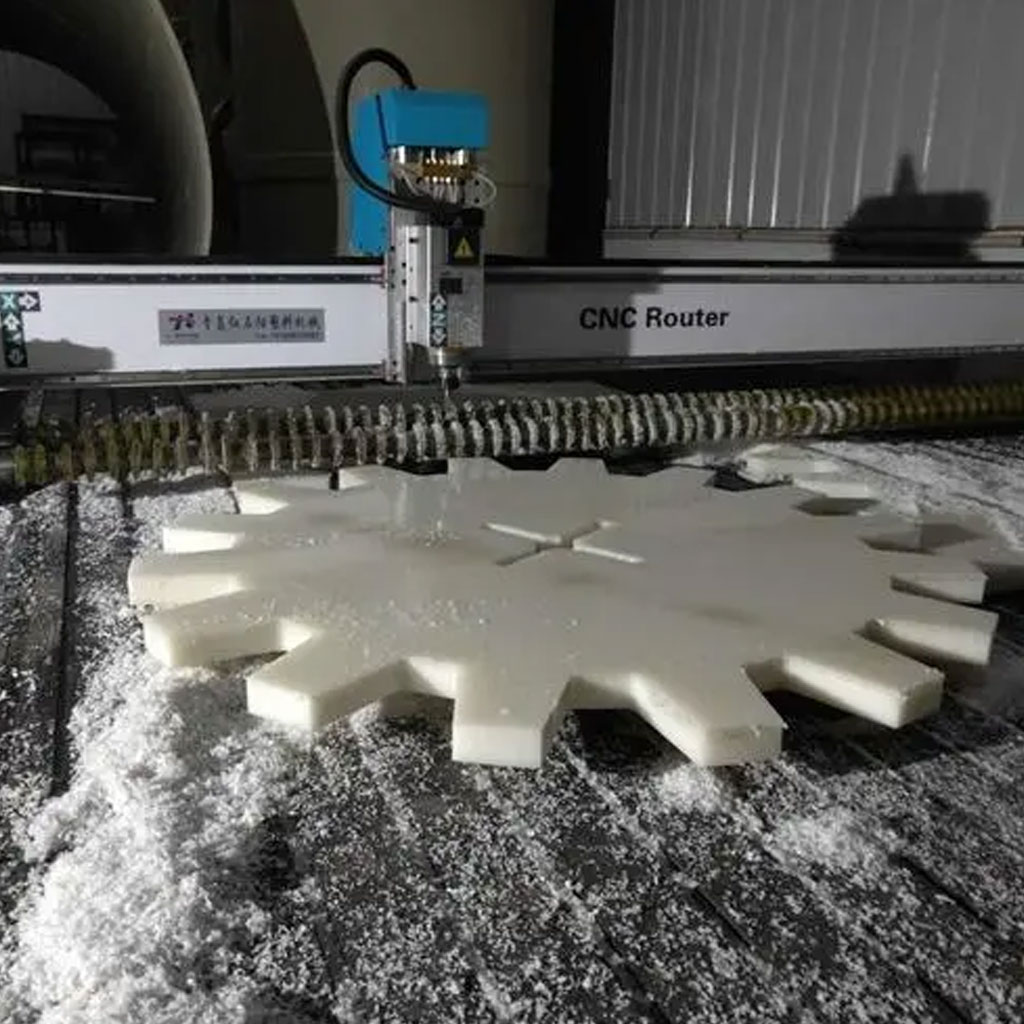

Our team of expert plastic laser cutters are skilled at creating parts that fit tight tolerances and are consistently produced over high volumes.We also provide a variety of finishes. Our laser cutter are fully-equipped with various cutting tools that allow us to create parts with tight tolerances and intricate designs. We can used cnc machines also add features such as threads, holes, and slots to your parts.

There are many reasons why our plastic laser cut are above other competitors. For one, our machines have high-quality laser tool holders and precision cutting tools. This ensures precise and accurate cuts, even on complex designs.

Our plastic laser cut machines are some of the most advanced and precise machines on the market today. With our cutting-edge technology, we can produce parts and products with exceptional accuracy and detail. Our laser cutter tools are versatile and can be used for various applications. Whether you need to cut small or large parts, our plastic laser machines can handle the job.

Our plastic laser cutting service and non-metal cutting department is cost-effective, and no job is too big or too small. The plastic cutting we offer at Be-Cu ensures high-speed automated routing of all types of plastics, and we can cut and manufacture plastics to meet any design requirements – from simple cuts to complex shapes, dual head and single head machines cut nested parts very efficiently.

Our Plastic Laser Cut Capabilities And Benefits

- Most Materials in Stock

- State-of-the-Art Laser Cutter

- Cut Parts from All Types of Plastics

- Many Products Annealed for Maximum Strength

- Custom Parts Made from Samples, Prints, or Sketches

- Post Machining Inspection with 100% Inspection Reports Available

- Precision Plastic Components, Custom-Cutting to Your Specifications

For more information on our plastic laser cut capabilities and what we can build for your company, get in touch with us today to get started.

What Plastics Is Best For Laser Cut?

Laser cutting is applicable to various types of plastic materials, each with its own characteristics and considerations. Here are some common types of plastics used in laser cutting:

Acrylic (PMMA)

It comes in various colors and finishes.

Laser-cut acrylic edges are typically smooth and flame-polished.

Polyvinyl Chloride (PVC)

Some laser cutters may have specific ventilation requirements for working with PVC.

Polycarbonate (PC)

Can be used for applications requiring a tougher material than acrylic.

Polyethylene (PE) and Polypropylene (PP)

Laser cutting can be done, but the edges may not be as polished as with acrylic.

ABS

Polyoxymethylene (POM) or Acetal

Laser cutting can be used for POM, but it may produce a slight yellowing at the cut edges.

Polyethylene (PEEK)

Laser cutting is possible, but PEEK has a high melting point, so laser parameters need to be carefully controlled.

Polytetrafluoroethylene (PTFE)

Laser cutting PTFE requires specialized equipment and precautions due to the material’s characteristics.

When laser cutting plastics, it’s essential to consider the specific characteristics of the material, including its melting point, release of fumes, and potential for discoloration. Always check the manufacturer’s guidelines for both the laser cutter and the plastic material to ensure safe and effective cutting. Additionally, conduct test cuts on scrap material to optimize settings before cutting the final design.

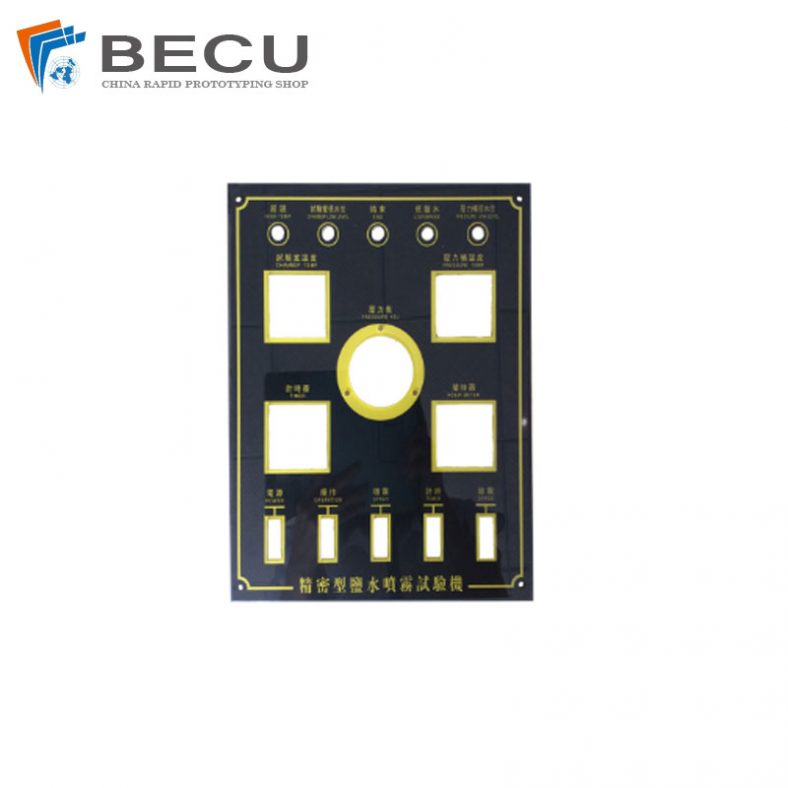

Custom Laser Cut Plastic Projects & Parts Case Studies

Using our top of the Plastic laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of Plastic. Using our high speed Plastic laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision Plastic laser cutting prototypes and parts from our valued customers.