Laser Cutting For PTFE

PTFE is a synthetic fluoropolymer of tetrafluoroethylene and is known for its non-stick properties, chemical resistance, and high-temperature stability.

Laser cutting is a precise and efficient method for cutting a variety of materials, including polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon. PTFE can be cut using relatively low laser power settings because it vaporizes easily. The specific power requirements depend on the thickness of the PTFE sheet.

Teflon’s high coefficient of expansion and stress creep properties can make it difficult to achieve tight laser cutting tolerances. It’s essential to design your application with PTFE’s inherent properties in mind, instead of trying to force the polymer to act against its nature.

Be-Cu prototype inc custom made-to-order laser cutting ptfe/teflon plastic component parts and ptfe cnc machining for commercial and industrial customers & OEMs. We work to your specifications and can produce small prototype quantities when needed, and short run and larger production run quantities.

PTFE/Teflon Plastic Material Properties

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a high-performance plastic with unique material properties. Here are some key properties of PTFE:

| Property | Value/Description |

|---|---|

| Chemical Formula | (C2F4)n |

| Common Name | Polytetrafluoroethylene (PTFE), Teflon |

| Density | 2.15 – 2.3 g/cm³ |

| Melting Point | 327 °C (621 °F) |

| Thermal Conductivity | 0.25 W/(m·K) |

| Coefficient of Friction | 0.05 – 0.10 (dynamic) |

| Tensile Strength | 20 – 30 MPa |

| Elongation at Break | 200 – 400% |

| Hardness (Shore D) | 50 – 65 |

| Dielectric Constant (ε) at 1 MHz | 2.1 – 2.3 |

| Dissipation Factor (tan δ) | 0.0002 – 0.0004 |

| UV Resistance | Excellent |

| Water Absorption | < 0.01% |

| Thermal Expansion Coefficient | ~ 135 x 10^-6/°C (below 19 °C) |

| Specific Heat Capacity | 1.0 – 1.4 J/(g·K) |

PTFE Laser Cut Manufacturer – Teflon Laser Cutting Service

Be-Cu Prototype is now offering complete PTFE Laser Cutting Precision Cut Service.

Be-Cu.com

Be-Cu stands at the forefront of the industry, blending Expertise in PTFE Laser Cutting Services with an unwavering commitment to quality and affordability. This combination has set us apart as a leader in PTFE cutting . We utilize our in-house PTFE compression molding capabilities to create stock forms and near net shapes for efficient cutting of custom ptfe parts. Our top PTFE Laser Cutting Expertise showcases advanced skills and in-depth knowledge in PTFE cutting to meet the stringent quality standards of our clients. This expertise is crucial in maintaining our position as a leading provider in the Laser Cutting industry.

Our approach to PTFE Laser Cutting Solutions at Be-Cu is holistic, focusing on delivering efficient and effective services.

Benefits Of Laser Cutting PTFE

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient Laser Cut factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

The Material Of PTFE Laser Cut

Polytetrafluoroethylene (PTFE), when subjected to laser cutting, remains classified as a thermoplastic material. PTFE is inherently a non-melting material, and laser cutting is achieved by a localized heating process rather than full melting. The laser beam heats the PTFE to the point where it vaporizes or becomes pliable, allowing for the creation of precise cuts.

In terms of material classification, PTFE is part of the thermoplastics family. Thermoplastics are polymers that can be melted and re-molded multiple times without undergoing significant chemical changes. PTFE, like other thermoplastics, exhibits the property of becoming pliable when heated and solidifying upon cooling.

The laser cutting of PTFE falls under the broader category of laser processing of thermoplastics. Laser cutting provides advantages for thermoplastic materials, including precision, minimal heat-affected zones, and the ability to create intricate designs.

It’s worth noting that the classification is based on the behavior of the material under heat and its ability to be reshaped. PTFE, even though it has a high melting point, undergoes localized heating during laser cutting, allowing it to be shaped and cut without undergoing a complete melt.

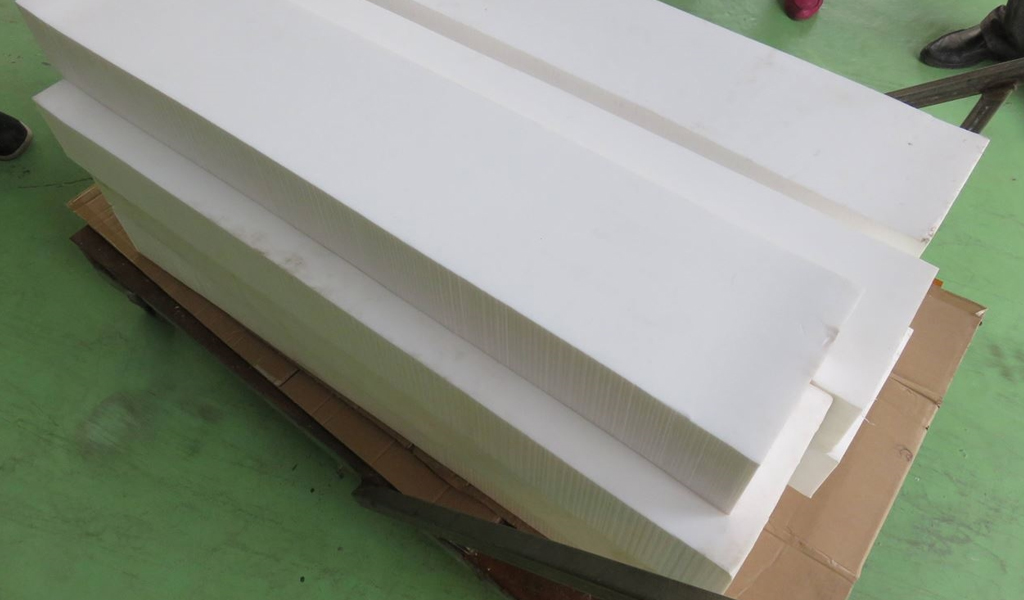

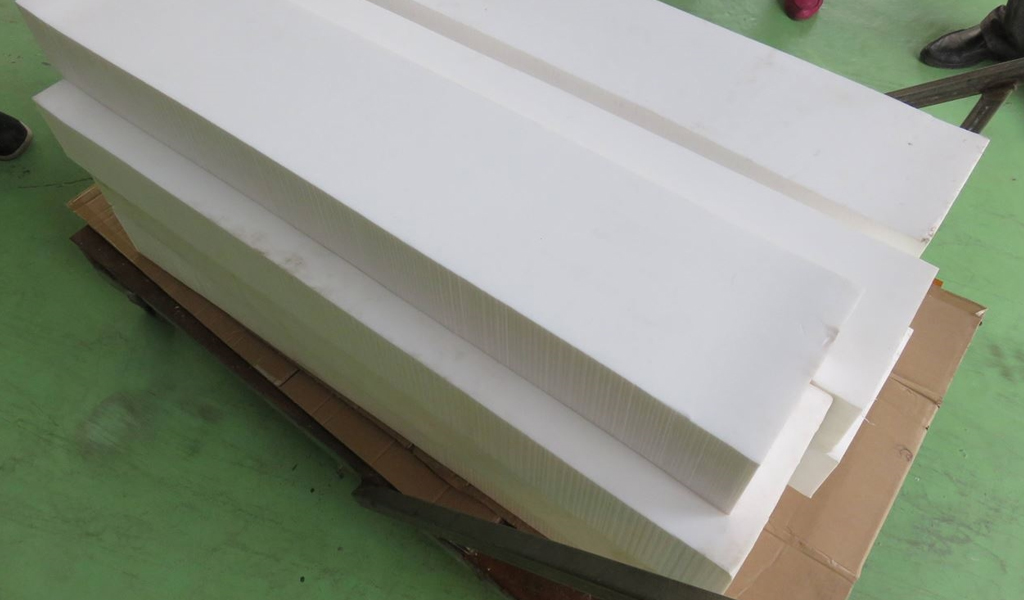

Custom Laser Cutting PTFE Projects & Parts Case Studies

Using our top of the PTFE laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of PTFE. Using our high speed PTFE laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision PTFE laser cutting prototypes and parts from our valued customers.