What Is Inconel Etching

Inconel etching is a crucial process in the fabrication and manufacturing of components made from Inconel alloys. Inconel, a family of austenitic nickel-chromium-based superalloys, is known for its exceptional resistance to high temperatures, corrosion, and oxidation. Its unique properties make it indispensable in various industries, including aerospace, automotive, chemical processing, and marine engineering. However, working with Inconel presents challenges due to its hardness and resistance to traditional machining techniques. Etching emerges as a preferred method for shaping and patterning Inconel components with high precision and efficiency.

In the realm of modern manufacturing and engineering, the pursuit of precision and innovation stands as an unyielding cornerstone. From aerospace applications to medical devices, the demand for materials capable of withstanding extreme conditions while maintaining intricate designs continues to propel the boundaries of what is achievable. In this landscape, Inconel, a family of superalloys renowned for its exceptional resistance to corrosion and high-temperature environments, emerges as a stalwart companion in the pursuit of technological advancement.

At the nexus of this quest for excellence lies BE-CU, an industry leader in providing cutting-edge solutions for precision manufacturing challenges. With a rich tapestry of expertise spanning decades, BE-CU has cemented its reputation as a trailblazer in the field of chemical etching services. Leveraging state-of-the-art technology and a relentless commitment to quality, BE-CU has consistently pushed the envelope of what is achievable in precision manufacturing.

Inconel Etching Service – Types of Inconel® for Etched Parts

Central to BE-CU’s repertoire of services is its unparalleled Inconel etching service, a cornerstone offering that epitomizes the company’s dedication to excellence and innovation. Inconel, a nickel-chromium-based superalloy prized for its exceptional mechanical properties and resistance to oxidation and corrosion across a broad spectrum of temperatures, presents unique challenges and opportunities in the manufacturing landscape. BE-CU’s Inconel etching service stands as a testament to the company’s ability to not only meet these challenges but to surpass them with unparalleled precision and efficiency.

At the heart of BE-CU’s Inconel etching service lies a deep understanding of the unique properties and characteristics of this formidable material. Inconel’s exceptional resistance to oxidation and corrosion, coupled with its high tensile strength and creep resistance, make it an ideal candidate for a wide array of demanding applications. However, its formidable nature also presents significant challenges when it comes to traditional machining and fabrication techniques. It is in this crucible of challenge and opportunity that BE-CU’s expertise truly shines.If you want expert support from a vendor you can trust, look no further than the precision etching services offered by Be-cu.com for your next inconel project.

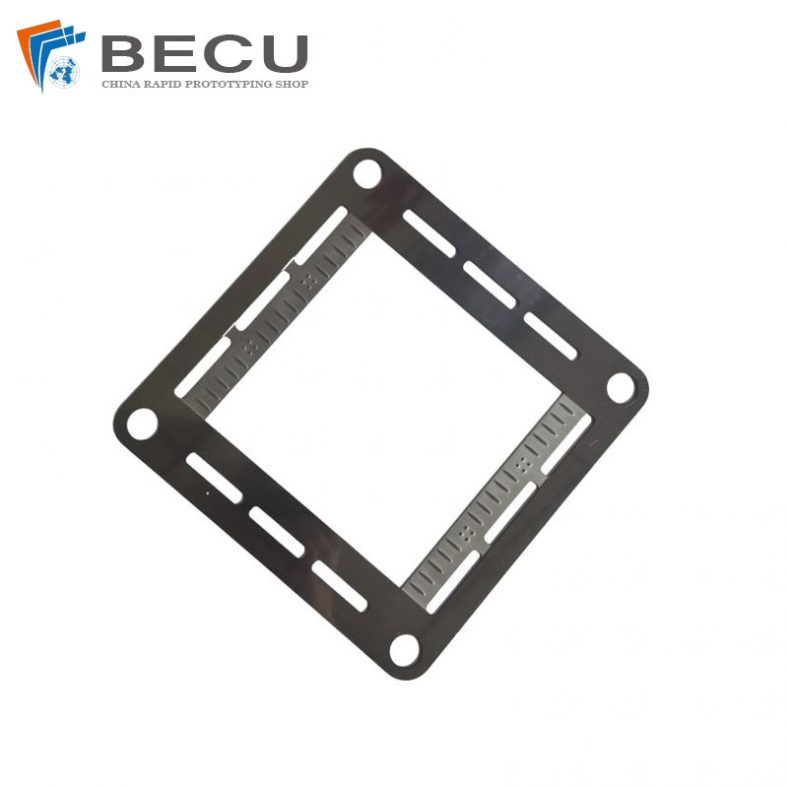

BE-CU etching works primarily with 2 types of Inconel: Inconel® 625 and Inconel® 718. Most of the Inconel® parts we have etching include complex cooling channels, aerodynamic surfaces, and identification markings with precision. Many of the components we etched require tight extremely fine surface finish results in order to maintain sealing surfaces or other critical-to-function features. We have developed methods to meet or exceed even the most critical demands.

Etching Inconel® 718

Inconel® 718, a precipitation-hardenable nickel-chromium alloy, owes its remarkable properties to a strategic combination of elements including nickel, chromium, iron, niobium, and molybdenum, among others. This alloy exhibits exceptional mechanical strength and stability across a wide range of temperatures, making it ideal for applications in extreme environments. Its resistance to corrosion and oxidation further solidifies its position as a material of choice for critical components in aerospace engines, gas turbines, and nuclear reactors.

Etching Inconel® 625

Inconel® 625, a nickel-based superalloy, derives its remarkable properties from a unique combination of elements including nickel, chromium, molybdenum, and niobium, among others. This alloy exhibits exceptional resistance to corrosion and oxidation, as well as high strength and toughness at elevated temperatures. These characteristics make it an ideal material for applications requiring reliability, durability, and performance in harsh environments. From chemical processing to offshore drilling, Inconel® 625 is a material of choice for critical components subjected to corrosive media, high temperatures, and mechanical stress.

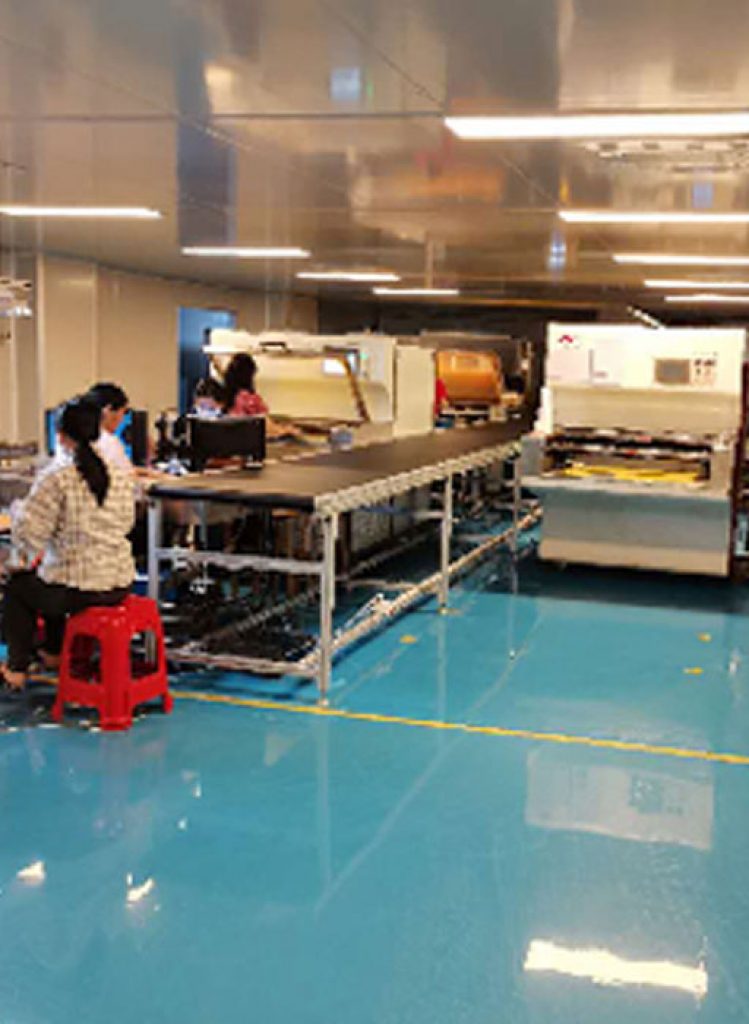

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

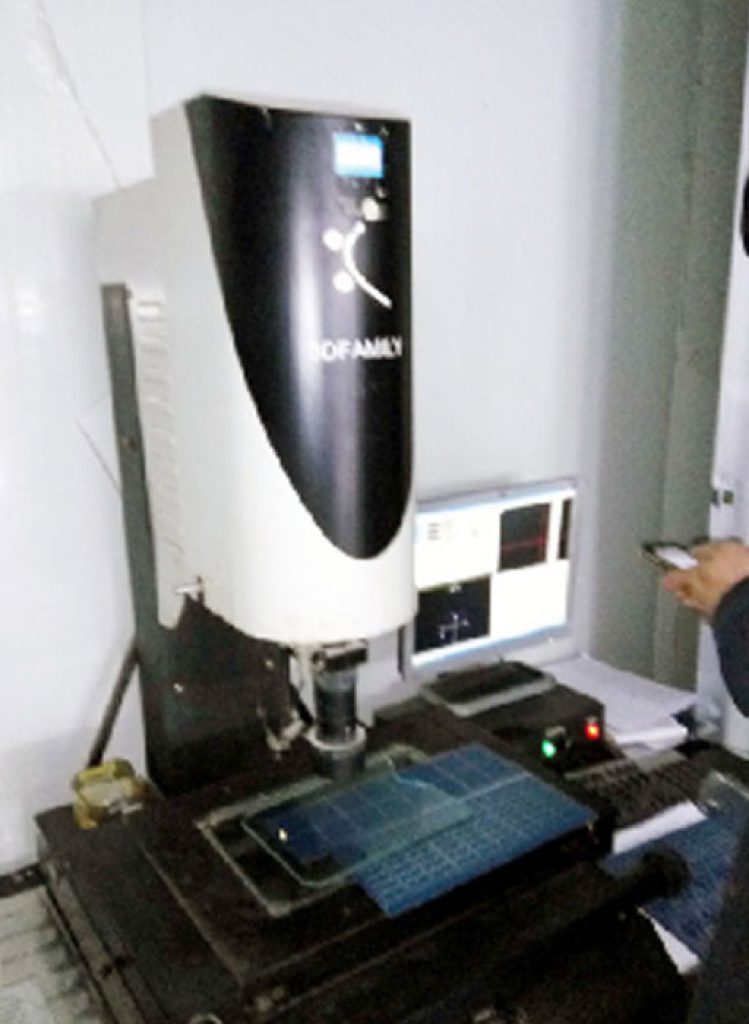

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Inconel Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Inconel Chemical Etching Parts & Case Studies In China

As one of professional Inconel Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Nickel material characteristics. So we can offer you the best etching Inconel solution according to your requirements of Inconel parts and products.

-

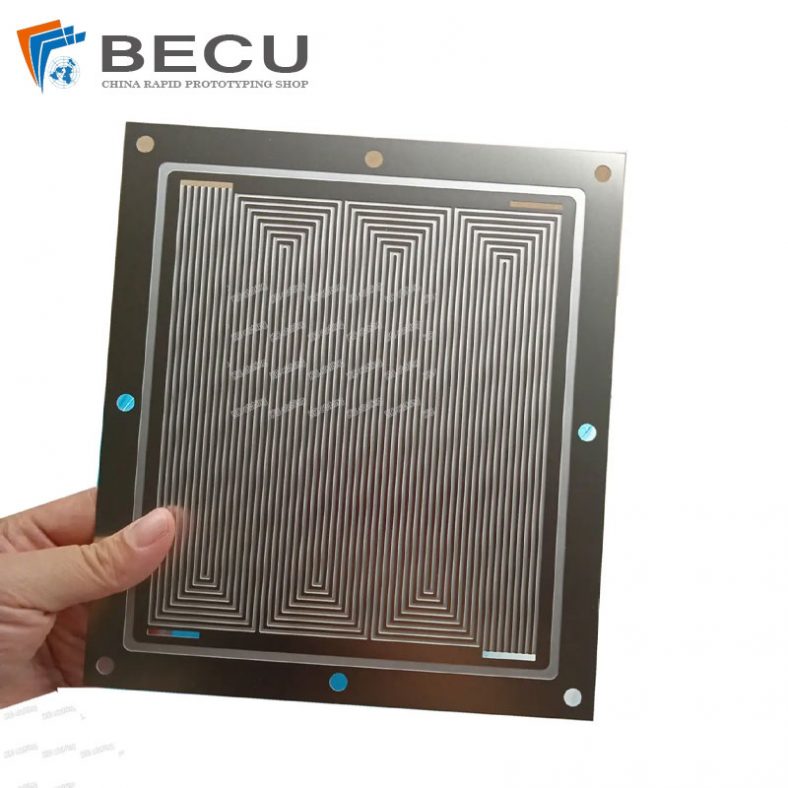

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

Laser Cut And Etching 303 Jewelry Pendant

-

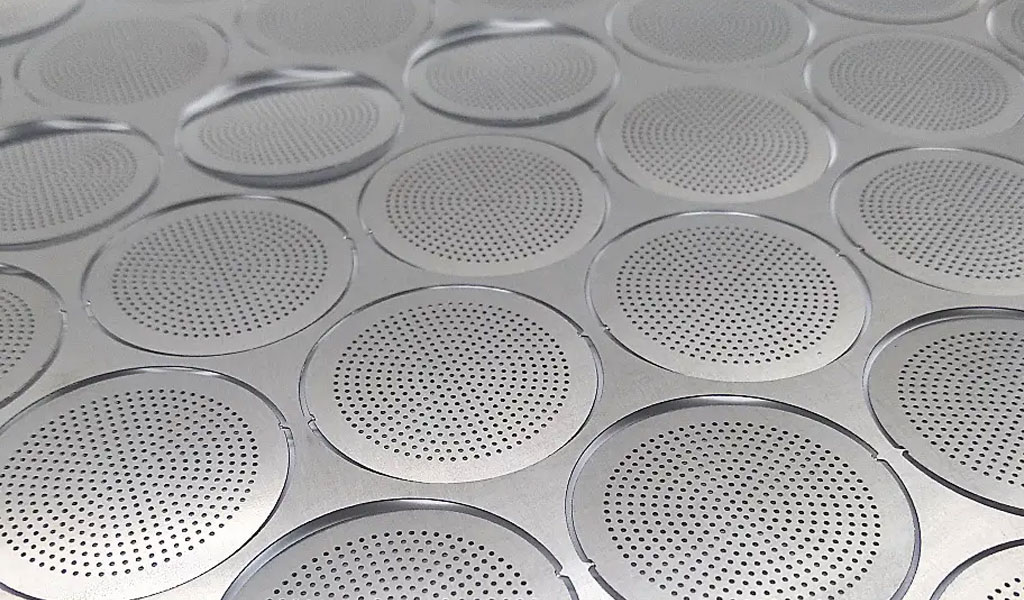

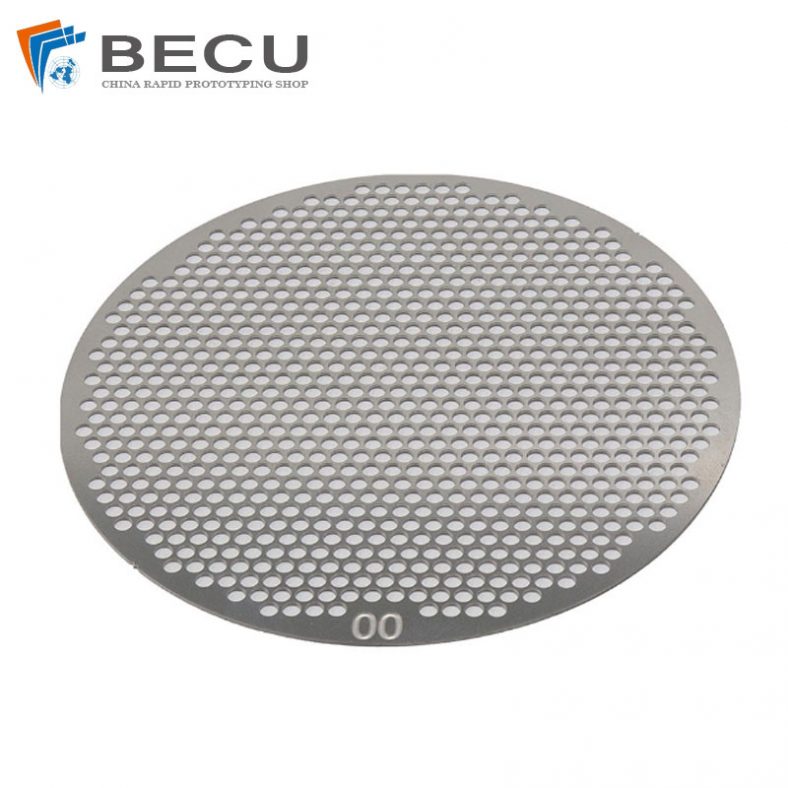

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

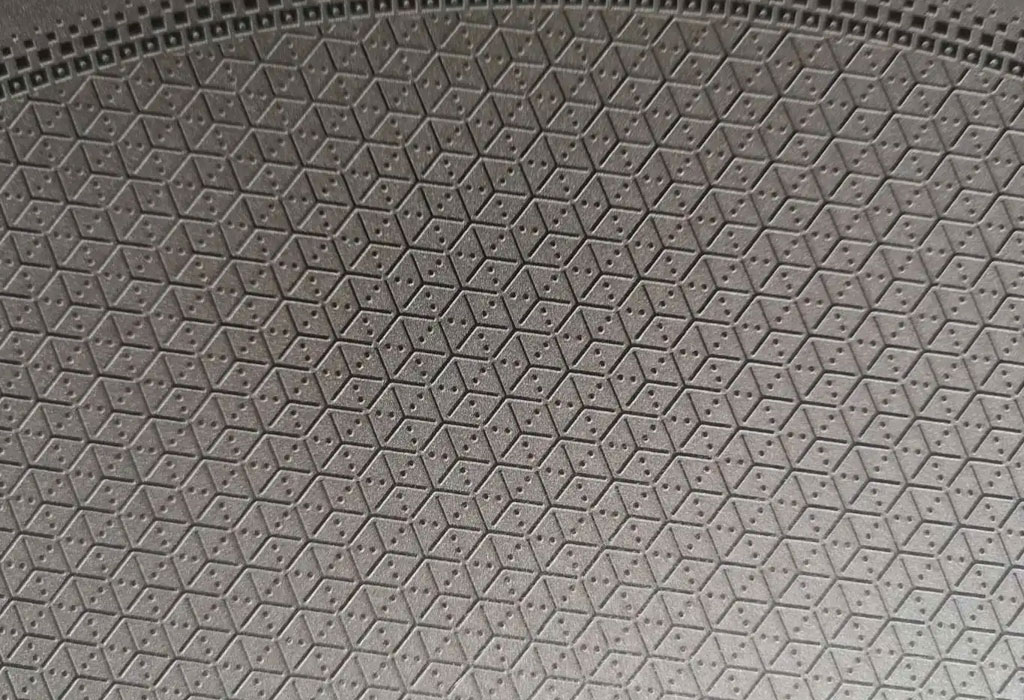

Precision Etching Automotive Audio Grille

-

Metal Etching 5 Inch Round Car Horn Protection Net

Surface Finishing Options for Inconel Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Online Cooperate With Inconel Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.