Tungsten Steel Mold Parts

- No.: Tungsten Machining

- Color: Custom

- Surface Treatment: Custom

- Product Material: Tungsten-Copper

- Proofing Cycle: 7 days(100000 pcs/M)

- Accuracy: 0.005mm

- Hardness: 58-62

- Squareness: 100mm

- Product Category: Mold Parts

- Production Process: Sintering

- Size: According To Customer’s Drawings

High-Quality Custom Precision Grinding Tungsten Steel Mold Parts

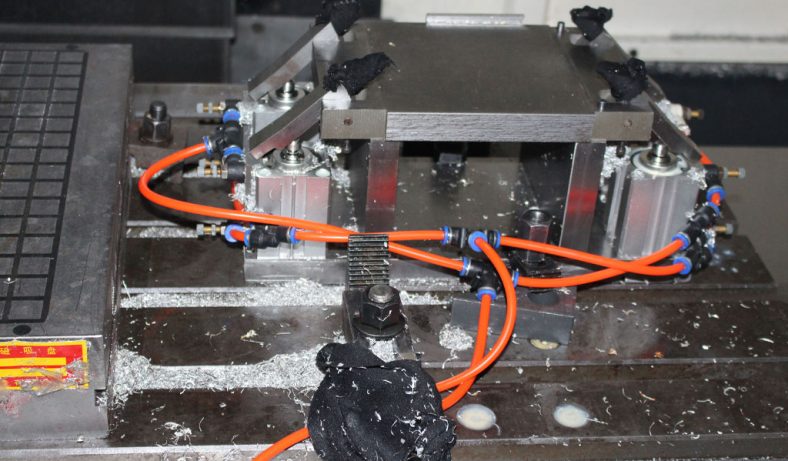

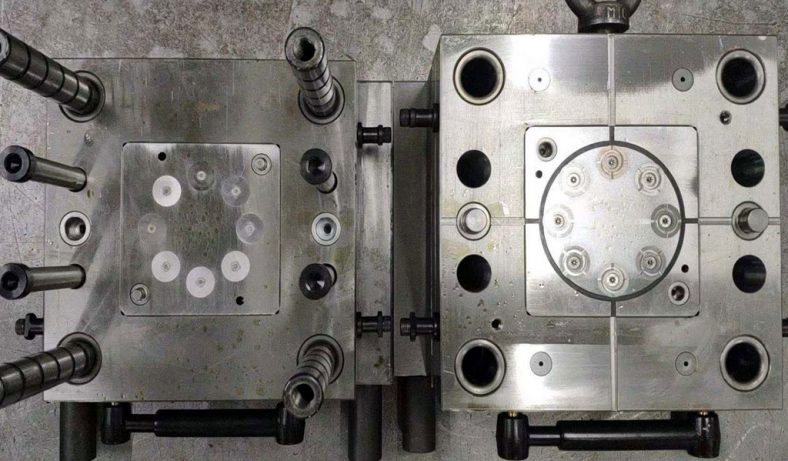

Precision grinding is a critical process in the manufacturing of tungsten steel mold parts. This process involves the meticulous removal of material from the workpiece to achieve the desired dimensions, surface finish, and tolerances. Tungsten steel, known for its high hardness and resistance to wear, is a preferred material in mold making due to its durability and ability to withstand high temperatures. Precision grinding of tungsten steel mold parts is essential in various industries, including automotive, aerospace, electronics, and medical device manufacturing, where high precision and reliability are paramount.

The Advantages Of Custom Precision Grinding Tungsten Steel Mold Parts

- Precision mold manufacturing company, quick response and easy communication.

- Simple quoting process, competitive price with high quality products.

- Professional team provides all-round technique support and secondary services for each machining project. State of the art service meets or exceeds your expect.

- Strict testing and quality mold production control, 100% inspection before shipment.

- Good machining capabilities.

- Reliable finishing and packaging to ensure the safety during the transportation.

We also make all kinds of electrode and precision inserts from provided drawing, whether molded in or fixed in after molding.With the highly trained molding engineers,operators, technicians and designers’ thorough understanding of mold building and capability,the inserts we make could reach +/-.002mm tolerance,which will fit in with your mold perfectly to assure high reliability and smooth running production,as well as to save lots of your time and cost.

Be-cu Company Mold Making Policy

| Fast DFM Reports | Although we check your design feasibility when providing a quote, we can provide a fast and thorough DFM (design for manufacturability) report before production begins. In the DFM report, we’ll identify any errors or issues that might cause a manufacturing problem down the line. |

| Wide Range Of Molds | We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly. |

| Fast Turnaround | Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster. |

| Molding Capabilities | Be-cu can ship your molds to you directly, but we can also handle injection molding and other production services to deliver you prototypes and final parts using those molds. |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

China Top Mold Parts and Mold Making Company

BE-CU.com is a professional manufacturer of precision mould parts. We have the ability to manufacture all kind of precision mold parts, they are commonly used in precision plastic mold, auto mold, medicine mold, and precision automation machine.Our products including: Mold cavity,inserts,core pin,punches, ejector/sleeves pins, sleeves, leader pins, guide sprue bushings, ejector blades etc.We are fully equipped with CNC machining centers, precise surface grinder, numerical control machine, punch formers and precision centerless grinding machines etc.

BE-CU Precision Parts Co.,Ltd. is established in 1995, is a professional manufacturer of precision mould parts. Our factory, located in the mould town--Chang'an. It is a professional company in research, development and manufacturing of precision mould components,we have over 30 years experience in this field,our advanced precision equipment and scientific quality control ensures customers satisfaction.

Our complete and advanced mold making facility provides a fundamental advantage as a complete product solution partner. Whether redesigning an existing mold or embarking on a brand new project, our team is able to deliver the highest quality tooling for molding with some of the shortest lead times in the industry.Our tool room is equipped with the latest resources in mold making technology, including CAM, CNC milling, grinding, EDM, inspection and more. These characteristics, coupled with a highly skilled staff encompass our mold-making department.Whatever you need prototype molds for the short-run production, or mass production molds for millions shots, Be-cu.com can handle them for you smoothly.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

OEM Stainless Steel Press Brake Tooling