Copper Sheet Metal Fabrication

Copper is the metal that binds the world’s telecommunication systems and is considered one of the best electrical conductors.Copper has a density of 8.96 and a melting point of 1083°C. It has good electrical and thermal conductivity, excellent plasticity, and is easy to be processed by hot pressing and cold pressing. Copper is second only to silver in electrical and thermal conductivity. Copper has good weldability and corrosion resistance, and can be processed into various semi-finished and finished products by cold and thermoplastic processing.

Copper is known for being the best electrical conductor and relatively low cost. Be-cu professionals find that copper sheet metal fabrication is a smooth process because copper is a good heat conductor that is easy to shape. Copper also has high corrosion resistance properties to rust, making copper machined parts popular for electrical applications.

Benefits of Copper In Sheet Metal Fabrication

All Copper have a high resistance to corrosion and heat making it a durable metal with a long lifespan.Copper is often able to withstand many years of use without showing signs of wear and tear. Other advantages include:

- High resistance to corrosion

- Easily cut, welded, formed, machined and fabricated readily

- Due to its strength, Copper can be used to reduce material thicknesses, reduce weight and costs

- 100% Recyclable

- Its unique hygienic properties makes it the first choice in hospitals, kitchens, food and pharmaceutical processing facilities

The Copper Alloy Grades Of Sheet Metal Fabrication

Copper and its alloys are widely used in modern mechanical engineering as structural, antifriction, electrical and other materials.There are two commonly used copper and copper alloy sheets, copper T2 and brass H62,

Copper T2 is the most commonly used pure copper with purple appearance, also known as red copper. It has high electrical conductivity, thermal conductivity, good corrosion resistance and formability, but its strength and hardness are much lower than brass, and the price is also very expensive. Mainly used as electrical, thermal and durable consumer goods corrosion components, generally used in power supply parts that need to carry large currents.

Brass H62 is a high-zinc brass with high strength and excellent cold and hot workability. It is easy to be used for various forms of pressure machining and cutting. Mainly used for various deep drawing and bending stress parts, its electrical conductivity is not as good as red copper, but it has good strength and hardness, and the price is relatively moderate. In the case of meeting the electrical conductivity requirements, brass H62 should be used instead. Red copper can greatly reduce the cost of materials, such as bus bars. At present, most of the conductive sheets of bus bars are made of brass H62, which has proved to fully meet the requirements.The comparison table with the old standard is shown in Table 1-1 below:

Copper Sheet Metal Fabrication Services – Sheet Metal Manufacturing Copper Parts Suppliers & Manufacturer

Copper alloys offer a lot of desirable properties that make them ideal for Sheet Metal Fabrication. But even after choosing the ideal copper alloy for your product design, the success of your manufacturing project still depends on your manufacturer.

You want to work with a manufacturer that has state-of-the-art equipment as well as highly qualified engineers and laser operators capable of sheet metal fabrication copper and copper alloys.

Be-cu.com is a popular name in the copper sheet metal fabrication industry and a leading provider of sheet metal manufacturing services across the globe. Backed by over 30 years of professional experience, we’ve helped many innovative companies create copper sheet metal components accurately while meeting their surface finish, precision, and tight tolerance requirements.

A highly skilled staff and advanced equipment allow us to deliver sheet metal fabrication copper parts with tolerances of ±0.0005” or better. Copper sheet metal fabrication technology ensures perfect repeatability, from the first part to the last, in any quantity, whether you need a single prototype component or high volume production runs with tens of thousands of pieces. Anything you require, from the simplest parts to the most intricate, can be manufacturing to match your exact specifications.Learn more about our cost-effective sheet metal fabrication services.

Why Use Our Copper Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal Copper parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication copper to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off copper laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom copper laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings u0026amp; finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

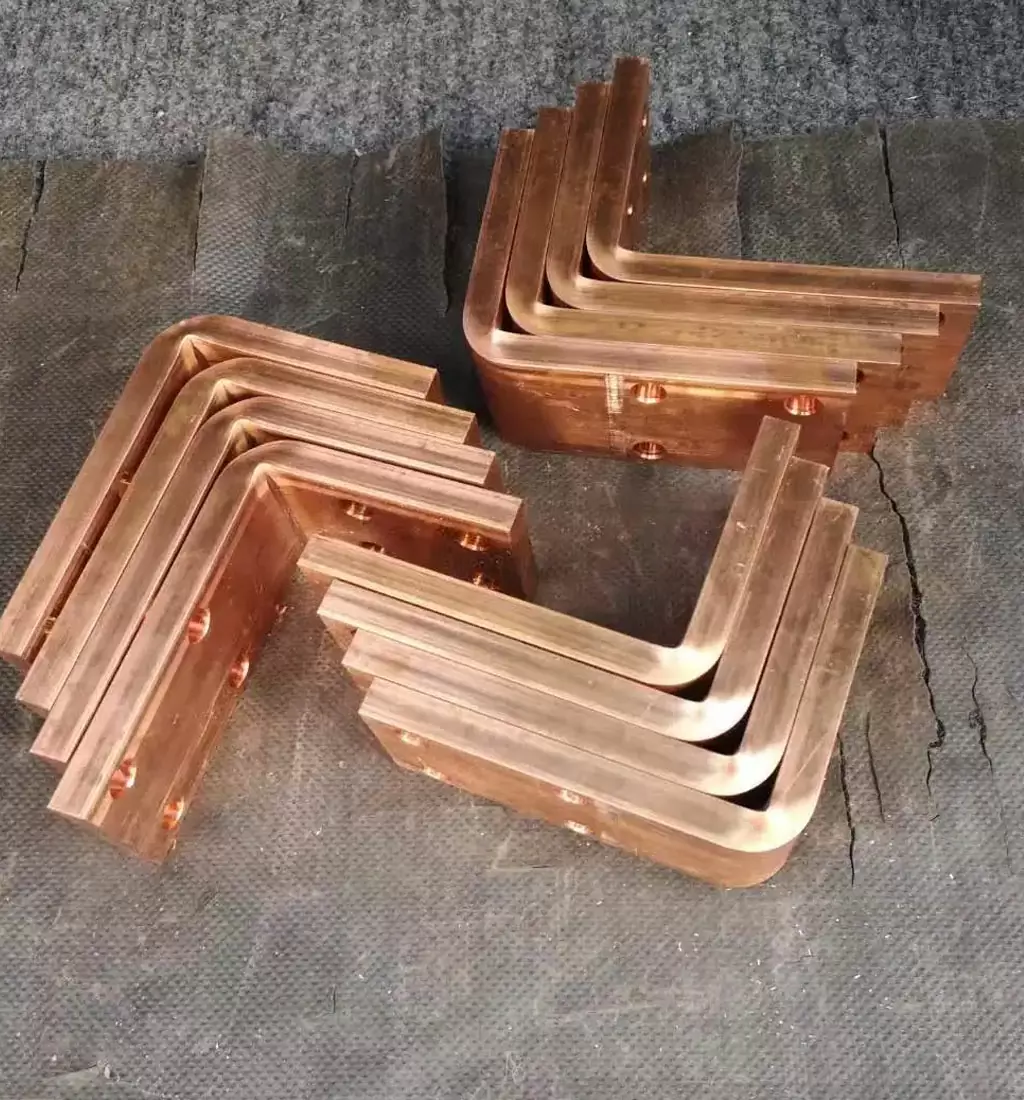

Our Capabilities And Case Studies Gallery Of Copper Sheet Metal Fabrication

As a single-source manufacturing solutions provider, Be-cu.com offers a comprehensive group of services, including Copper sheet metal fabrication.

Using sheet metal fabrication, we manufacture copper parts that exhibit a high degree of structural integrity.Copper sheet metal parts have no seams, enabling them to tolerate high pressure, and the sheet metal process itself realigns the grain structure of the metal to improve tensile strength. The enhanced metallurgical properties allow the use of lighter gauge metals to achieve the desired strength characteristics, which saves on material cost. sheet metal fabrication also results in high-quality finishes that reduce the need for secondary operations.

Inside our sheet metal fabrication department, we manufacture parts for a variety of purposes, from automotive applications to medical equipment. We have the capacity to achieve tolerances as close as ±0.005” for specialty applications that require extreme precision. Our sheet metal fabrication capabilities are supported by our machining, fabrication, and finishing departments, making the use of sheet metal fabrication virtually limitless. For more information about the sheet metal fabrication process or any of our other production capabilities, contact us directly.