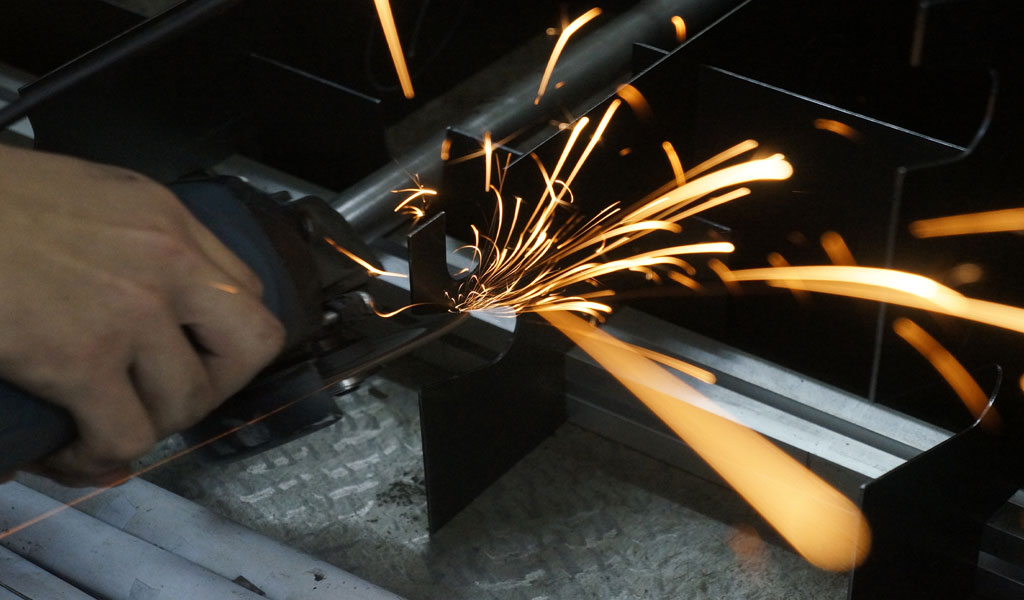

Mild Steel Sheet Metal Fabrication

Mild steel, also known as low carbon steel, is one of the most commonly used materials in the manufacturing and construction industries.

Its versatility, cost-effectiveness, and wide-ranging applications make it a crucial component of various products and structures. Mild steel fabrication, a process that involves shaping and manipulating mild steel into desired forms and products, plays a pivotal role in the production of a diverse range of goods.

Mild steel, characterized by its relatively low carbon content, typically ranging from 0.05% to 0.25%, stands in contrast to high carbon steels, which contain significantly higher levels of carbon. This lower carbon content makes mild steel more ductile, malleable, and easily workable, rendering it suitable for a multitude of fabrication processes.Its notable features include high weldability, formability, and a wide range of mechanical properties, making it an ideal choice for various applications where strength and versatility are essential. Additionally, mild steel is often preferred for its cost-effectiveness, making it a favorable material for mass production and large-scale manufacturing processes.

Mild steel fabrication involves a series of intricate processes, each contributing to the transformation of raw mild steel into the final product. The fabrication process typically begins with the cutting and shaping of the raw material, followed by various forming, welding, and finishing procedures. Advanced technologies and techniques such as laser cutting, CNC machining, and robotic welding have revolutionized the fabrication process, enhancing precision, efficiency, and the overall quality of the final output. Moreover, the incorporation of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has significantly streamlined the fabrication process, enabling manufacturers to create complex and intricate designs with unparalleled accuracy and intricacy.

Mild Steel Grades Used During Sheet Metal Fabrication

The choice of mild steel grade for sheet metal fabrication depends on the specific requirements of the project. While mild steel grades may vary slightly depending on the region and specific standards, the following are some common mild steel grades used in sheet metal fabrication:

Mild Steel (MS) 101

Mild Steel (MS) 102

Mild Steel (MS) 103

Mild Steel (MS) 104

Mild Steel (MS) 105

Mild Steel (MS) 106

The choice of grade depends on factors like the required mechanical properties (e.g., strength, ductility), the intended use of the fabricated components, and cost considerations. Keep in mind that the specific chemical composition of these grades may vary slightly depending on the manufacturer and regional standards. It’s important to ensure that the selected grade meets the project’s specifications and complies with relevant industry standards and regulations to ensure the safety and performance of the fabricated components.

Custom Mild Steel Sheet Metal Fabrication Service In China

Be-Cu prototype is a leading provider of Mild Steel Sheet Metal Fabrication services, catering to the diverse needs of industries across the globe. With a strong commitment to quality, innovation, and customer satisfaction, we have established ourselves as a trusted name in the sheet metal fabrication industry.

At Be-Cu.com, quality is the cornerstone of our operations.Our core expertise lies in Mild Steel Sheet Metal Fabrication. Whether you need customized components, prototypes, or large-scale production runs, we have the capabilities to fulfill your requirements. Our services include:

- CNC Laser Cutting For Mild Steel

- CNC Punching For Mild Steel

- CNC Bending and Forming For Mild Steel

- Welding and Assembly For Mild Steel

- Powder Coating and Finishing For Mild Steel

Be-Cu mild steel sheet metal fabrication company are a partner dedicated to your success. Be-Cu prototype has an experienced team of design experts who will create various product design and manufacturing solutions through CAD/Solidworks, and aesthetic designs for various application scenarios.With a rich history, a passionate team, and an unwavering commitment to quality, we are ready to tackle your most demanding fabrication challenges. Contact us today and experience the difference.

Why Use Our Mild Steel Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal mild steel parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication mild steel to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off mild steel laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom mild steel laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other mild steel sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Our Case Studies Gallery Of Mild Steel Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom steel sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

-

LCD Display Advertising Machine Sheet Metal Frame

-

Custom 32 Inch Ordering Machine Kiosk Chassis

-

SPCC Sheet Metal Fabrication Financial Device Enclosure