Military Sheet Metal Fabrication

Military sheet metal fabrication plays a crucial role in the defense and aerospace industries. It involves the design, cutting, bending, and assembly of sheet metal to create various components used in military equipment, vehicles, aircraft, and more. This process requires precision and expertise to meet the high standards of quality, durability, and safety that are essential for military applications.The components produced through this process are integral to the functionality, safety, and success of various military operations and equipment.

Historical Evolution of Sheet Metal Fabrication in the Military

In the realm of modern warfare, technological advancements have reshaped the landscape of military operations. Among the many fields of innovation, sheet metal fabrication stands out as a cornerstone of military engineering. This process, involving the cutting, bending, and shaping of metal sheets to create complex structures, plays a vital role in crafting everything from armored vehicles to aircraft components.

The roots of sheet metal fabrication in military applications trace back to ancient civilizations. The Romans, for instance, utilized metalworking techniques to craft armor, shields, and weaponry. However, it was during the Industrial Revolution that significant advancements in metalworking techniques paved the way for more complex and precise military fabrication.

The World Wars marked a turning point in the integration of sheet metal fabrication into military strategies. The need for rapid production of military vehicles, aircraft, and equipment drove the development of streamlined fabrication processes. Aircraft like the iconic Spitfire utilized intricate sheet metal structures that demonstrated the potential of this method in delivering both strength and aerodynamics.

Benefits of Sheet Metal Fabrication in Military Manufacturing

Sheet metal fabrication has become an indispensable process in military manufacturing due to its numerous benefits that align perfectly with the rigorous demands of defense applications. The precision, versatility, and efficiency offered by sheet metal fabrication techniques have revolutionized military equipment development and production.The key advantages that sheet metal fabrication brings to military manufacturing:

- Precision and Consistency

- Versatility in Design

- Strength-to-Weight Ratio

- Durability and Longevity

- Rapid Prototyping and Production

- Cost-Effectiveness

- Integration of Advanced Technologies

- Customization and Specialization

- Modular Assembly

Applications of Sheet Metal Fabrication in the Military

Sheet metal fabrication plays a pivotal role in the development and enhancement of various military equipment and systems. Its applications span across different branches of the military and contribute to the overall effectiveness and efficiency of defense operations. Here are some of the key applications of sheet metal fabrication in the military:

Armored Vehicles

Aircraft Components

Naval Vessels

Communication and Electronic Equipment

Field Infrastructure and Support Systems

Personal Protective Equipment (PPE)

Maintenance and Repairs

More Military Sheet Metal

Military Sheet Metal Fabrication – Metal Work for Military And Defense

Be-Cu has been at the forefront of technological innovation and engineering excellence, and we are proud to present our latest advancements in precision sheet metal fabrication tailored specifically to meet the rigorous demands of the military and defense sector.

In an era where defense technologies are advancing rapidly, the need for components that seamlessly blend strength, precision, and durability has never been greater. Our dedicated team of engineers and experts have been diligently working on refining our sheet metal fabrication processes to create components that set new standards in quality and performance. Through a combination of cutting-edge technology, state-of-the-art equipment, and an unwavering commitment to excellence, we are proud to offer solutions that cater to the unique challenges of the military and defense industry.

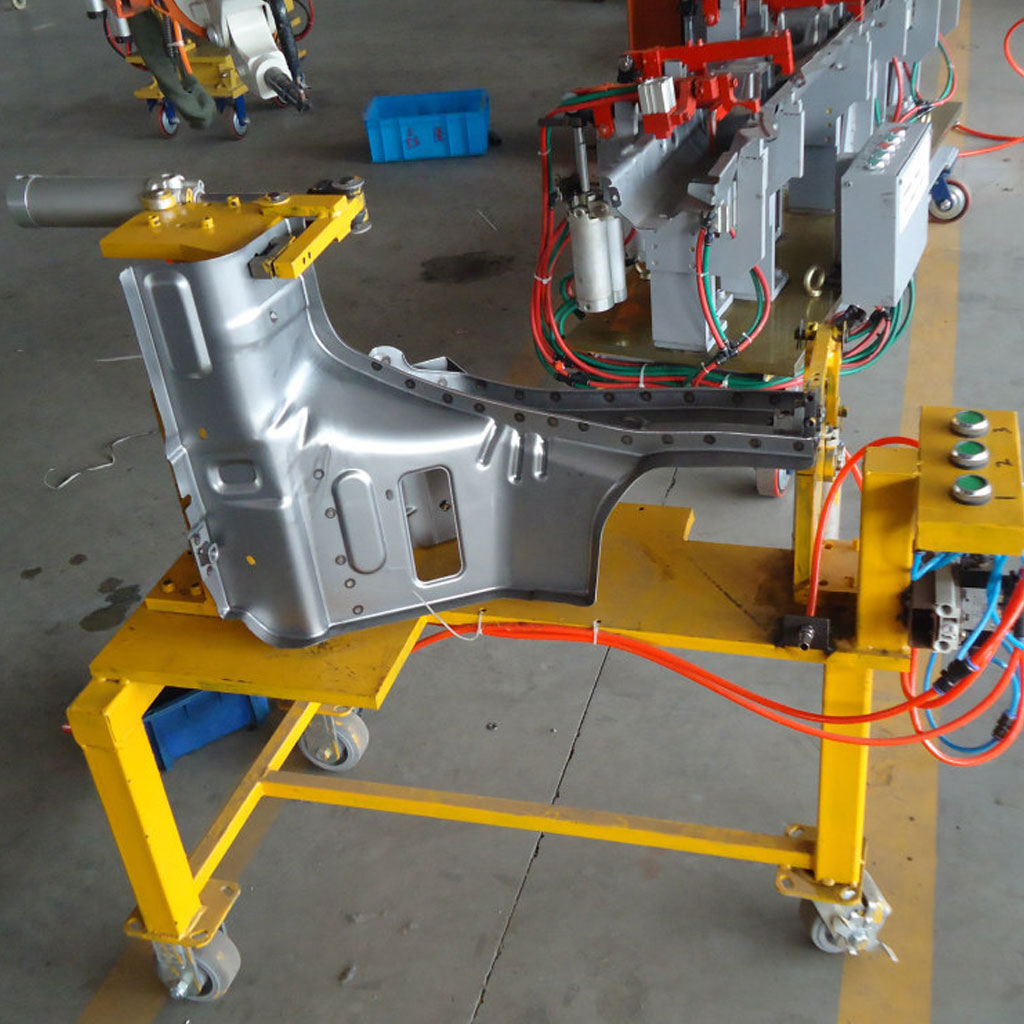

Our precision sheet metal fabrication capabilities encompass a wide range of applications crucial to defense operations.

From ballistic-resistant armor for armored vehicles to avionics enclosures that safeguard sensitive electronics within military aircraft, our components are meticulously crafted to withstand the most demanding environments. We understand that the military sector requires components that not only meet stringent specifications but also contribute to the overall effectiveness and safety of defense systems.

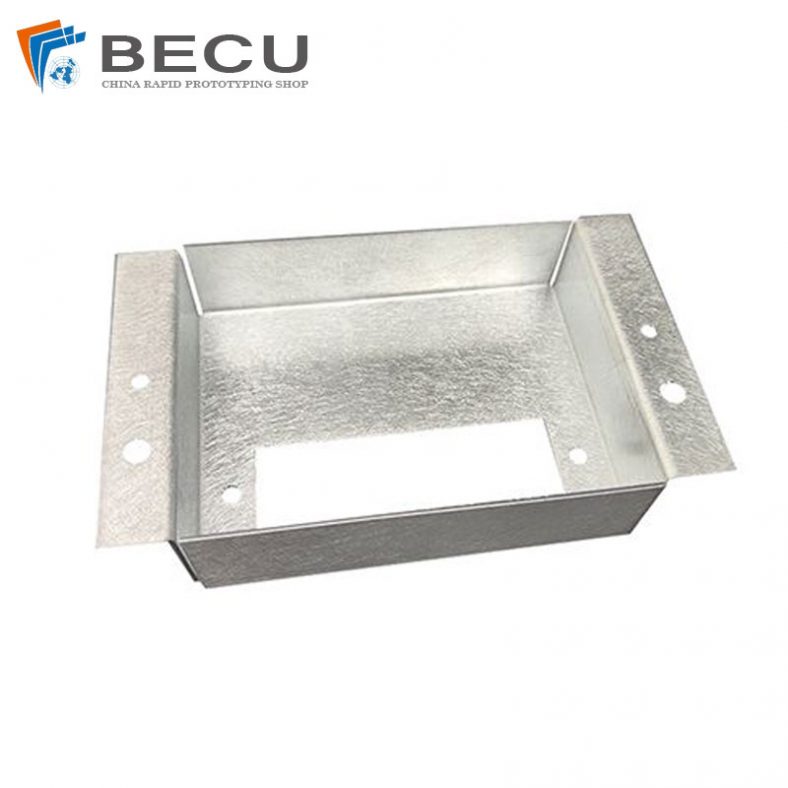

Precision fabrication services including metal and other alloy. Capable of forming parts from 12 in. to 90 ft. length, 0.015 to 0.125 in. material thickness and +/-0.005 in. tolerance. Large run and low to high volume production runs available.

If you need precision military sheet metal fabrication, call the experts at Be-Cu prototype today, or email us at [email protected].

Precision Military Components Made with Our Sheet Metal Fabrication

When you need precision parts manufactured for military applications, Be-Cu uses sheet metal machines to build components with the tightest tolerances. Our precision machining professionals can manufacture the best military-grade parts with the highest quality materials – from laser cutter to welding our technologically-advanced CNC bending machine create the most intricate military components at the most affordable cost.

Our metal fabrication experts work with the most lightweight and versatile materials, and our sheet metal experts fabricate military components with the most precise accuracy, meaning your military-grade parts are made to your exact specifications.Some of the components manufactured with our metal work machines include:

Ballistic-Resistant Armor

Avionics Enclosures

Radar and Sensor Mounts

Communication Equipment Enclosures

Weapon Platforms and Launch Systems

Vehicle Structural Components

When you need military-grade sheet metal parts made with the tightest tolerances, Be-Cu prototype is the way to go. Give us a call today to get more information on our military fabrication services.

Our Capabilities And Case Studies Gallery Of Military Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom Military sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

TA1TA2 Alloy Sheet Metal Manufacturing Machinery Support Parts

-

Sheet Metal Fabrication Aluminum 5052 Medical Box For Fire Fighting

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Fabrication Strongbox Enclosure

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure