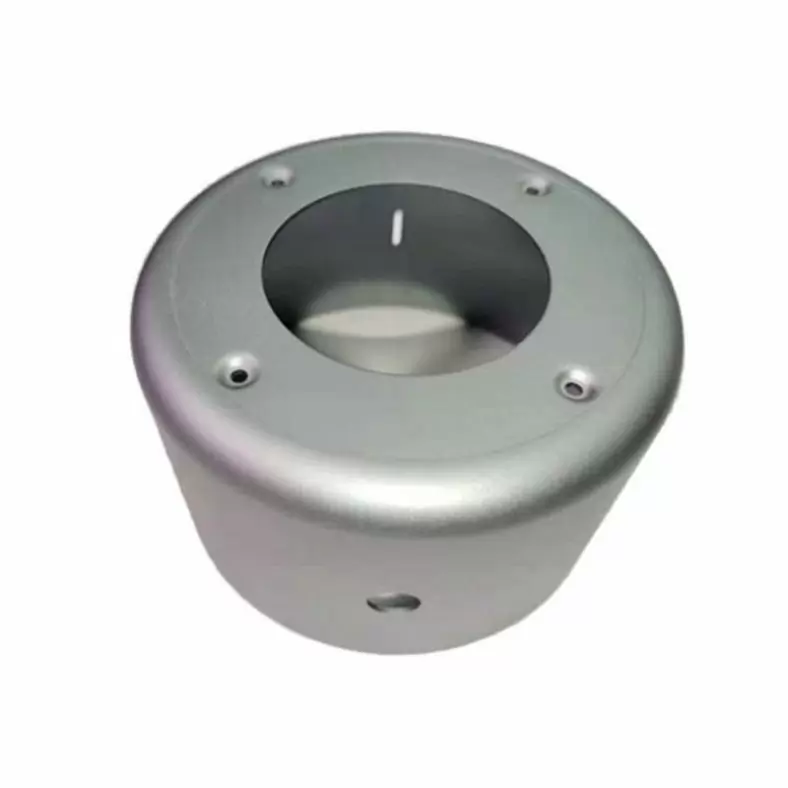

Medical Blood Gas Analyzer Bracket

- Material: SECC Steel

- Process: Metal Stamping And Mold Making

- Stamping Size: Custom Size

- Stamping Type: Metal Forming

- Stamping Mold: Compound Mold

- Tolerance: Custom

- Fine Blanking Method: Multi-Station

- Surface Treatment: Custom

High-Quality Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

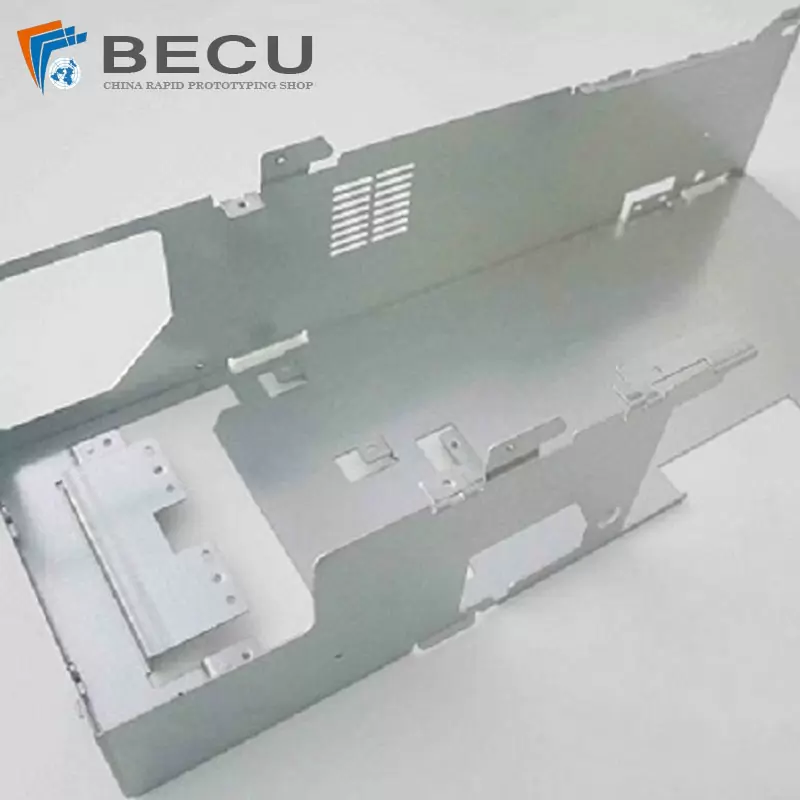

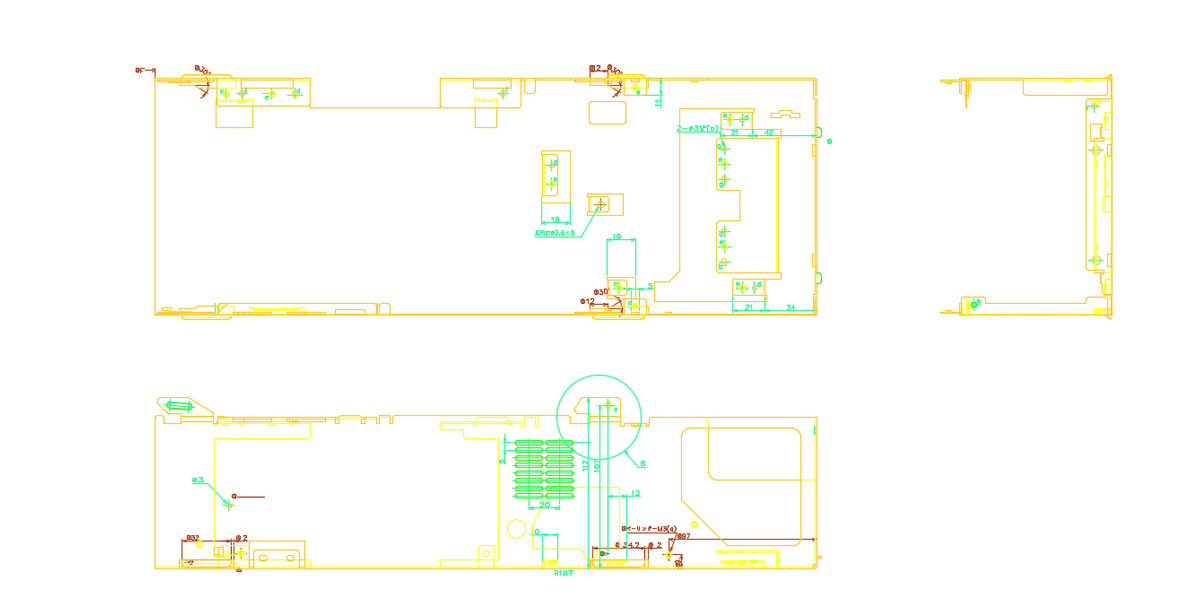

The galvanized sheet metal stamping shown is a bottom housing precision part designed by Be-cu.com for a bank unattended terminal circulation module. This case mainly shows the parameters, process and some common problems of the part from various aspects. Be-cu.com focuses on the development of value-added services for metal stamping products, and has won the “National High-tech Enterprise”.This part has the following features:

- The structure is stable. The part is made of galvanized sheet and has good tensile properties. The surface treatment layer also has outstanding anti-corrosion properties and moderate hardness;

- Beautiful, as shown in the figure, the product has a bright luster and can also be used as an appearance part;

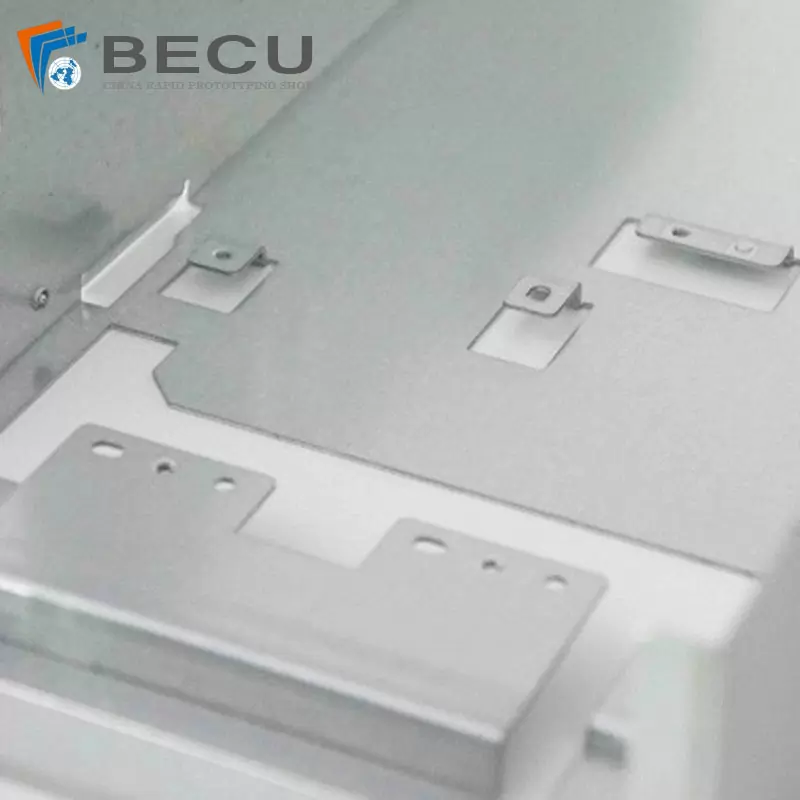

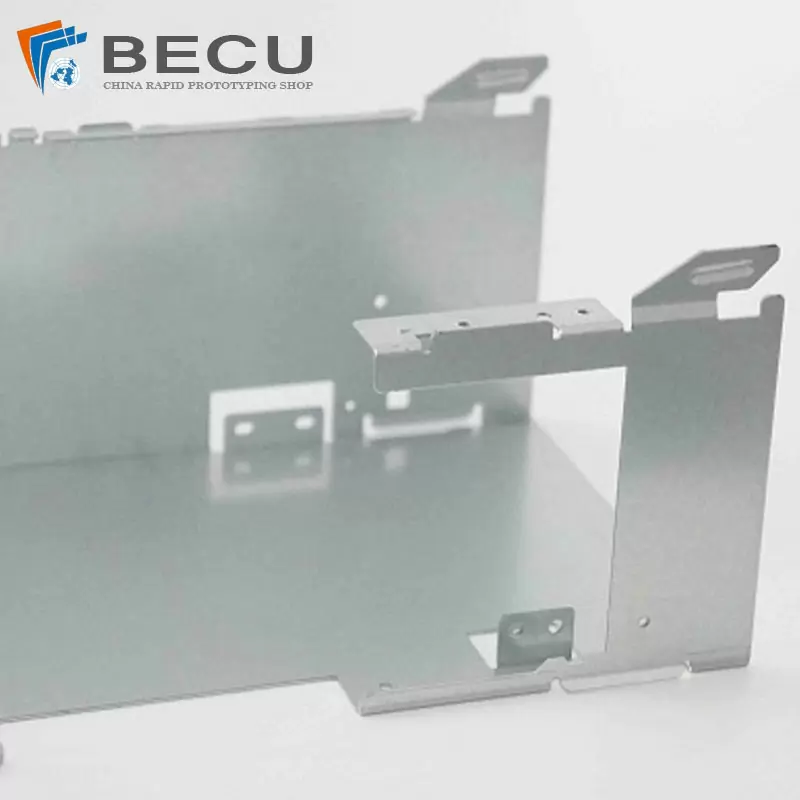

- Rigorous, the components have been optimized by 3 designers, and the bending angles and the positions and sizes of special-shaped holes have been tested and adjusted many times to ensure their assembly performance;

- Iterative, customized mass production, version upgrade and update can be flexibly dealt with, reducing cost input;

- Durability, the service life is more than 15 years;

Note: More detailed photos of products at the bottom of the page are used to show the product features of galvanized sheet metal stamping parts.

The Parameters Of Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

| Product Size | 433.5*158*112mm | Expand Size | 763*455*1mm |

|---|---|---|---|

| Product Material | SGCC | Material Thickness | 1.0mm |

| Product Weight | 931g | Mold Type | Single die & compound die, 7 sets in total |

| Surface Treatment | none | Processing Difficulty | complex |

| Size Tolerance | ±0.1mm | Angle Tolerance | ±0.3° |

The Production Process Of Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

| Serial Number | Process | Punch Tonnage | Process Description And Precautions |

|---|---|---|---|

| 1 | Composite Blanking | 200T _ | The shape and prototype hole of the product are punched out at one time, and at the same time, the size requirements of the product and the burr height requirements of the product can be guaranteed; |

| 2 | Beer Hole, Turn Pig’s Mouth, Convex Rice, Stretch | 200T | There are 4 processes in this trip, and the prototype is punched out. The structure of the stamping die in this trip is relatively complex and requires high precision; |

| 3 | Hit The Front, Turn The Pig’s Mouth, L Song | 200T | There are 3 processes in the stroke, the functions are as above; remove the peripheral burrs to prepare for subsequent processing ; |

| 4 | Press Nails | Auxiliary process | The pressure riveting process makes the parts and nuts (rivets) tightly combined to meet the assembly requirements of customers; |

| 5 | Teeth | 14-M3 | Tapping on 14 special holes, pay attention to the deviation of the vertical angle of the holes, and the deviation of the size of the holes is less than or equal to 0.1mm; |

| 6 | L Song, Z Song | 200T | Complete stamping and bending in 2 places in one stroke; |

| 7 | Beer Hole, W Song, L Song | 200T | In the fifth stamping stroke , the W-curve of the part is carried out through the die, and the angle requirement will be higher and the processing efficiency will be higher; |

| 8 | Teeth | 4-M3 | Tapping on 4 special holes, pay attention to the deviation of the size of the holes ; |

| 9 | V | 200T | The sixth stamping stroke ; |

| 10 | V | 200T | The last stamping and bending process; |

| 11 | Quality Inspection | Auxiliary process | Comprehensively check the dimensional error of galvanized sheet metal stamping parts and whether the appearance requirements after surface treatment are qualified; |

| 12 | Package | Auxiliary process | Packaging engineers design exclusive packaging solutions to ensure the quality of products in the follow-up operation process and avoid losses; |

Why Choose Our Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing Service?

- Are Cost-Efficient

- Manufacture Parts That Are Precision-Built

- Expert-Level Consultation and Design Assistance

- Provide Free Tool & Die Insert Storage and Maintenance

- Offer Complete In-House Tool & Die Capabilities

- BE-CU And His Core Supplier Sipx has large to small precision stamping presses. Our presses range from 40 to 700 tons, with bed sizes up to 150 inches and speeds up to 400 strokes per minute.

- Specializing in automated precision progressive dies, our feed capability ranges from 0.008 to 0.375 inch thick material with coil widths up to 50 inches and weights to 15,000 pounds.

Advanced Equipment to Create a Diverse Range of Designs,Sizes, and Thicknesses Large or Small Parts Can Be:

- – Pierced

- – Formed

- – Drawn

- – Extruded

- – Marked

- – And More!

Expert-Level Consultation and Design Assistance including:

- Engineering drawing analysis

- Design feasibility reviews

- Functionality assessments

- Confirmation of supply tolerances, cost ratios, and other important project considerations

- Informed recommendations about when to use stamping versus other technologies

Contact Be Cu Now for your Custom Metal Stamping, We are your best online Stamping services choice!

Specifications of Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

| Raw Material Thickness | 0.040″ to 0.375″ |

| Material | Stainless Steel (304, 305, 316, 430 & 434), Aluminum (3003, 5052, 6061), Cold Rolled Steel (1008, 1010), High Carbon Steel (1035), Nickel and Pre-plated Steel, Galvannealed Steel, Brass (80-20, 80-15, 70-30), Copper, HSLA. |

| Presses Ranging | 40 to 700 tons |

| Stamping Process | Flanging, punching, bending, necking, trimming, deep drawing, cold extrusion, precision blanking, bulging |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Zinc plating,Electroplating,etc |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Common Problems Of Precision Metal Stamping Bank Unattended Terminal Circulation Module Housing

1.What industry applications does your company’s galvanized sheet metal stamping parts have?

Answer: Our company has been deeply involved in the precision metal processing industry for 23 years, and is committed to the research and development and production of precision metal stamping structural products. The current products of galvanized sheet metal stamping parts are currently involved in the financial industry, communication cabinets, smart home, high-end medical and other industries. , has accumulated processing experience of various metal raw materials, and obtained 17 related patents .

Be-cu.com has been active in foreign advanced production equipment and training high-end technical talents for many years, laying a solid foundation, aiming to contribute more strength and scientific research and technical support in promoting the upgrading of China’s precision and intelligent manufacturing!

2. What are the advantages of metal stamping parts?

Answer: Describe from the following four points:

- Stability . The stamping die ensures the size and shape accuracy of the metal stamping parts, and protects the surface of the stamping parts during processing, and the life of the die is generally long, so the quality of the metal stamping is stable.

- The scope of application is large. Metal stamping can process parts with a wide range of sizes and complex shapes, such as stopwatches as small as clocks, as large as automobile longitudinal beams, covering parts, etc., plus the cold deformation hardening effect of the material during metal stamping, the strength of metal stamping and stiffness is high.

- High efficiency. The production efficiency of metal stamping processing is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because metal stamping relies on dies and stamping equipment to complete the processing. The number of strokes of ordinary presses can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute. It is possible to get a punch.

- Cost controllable. Metal stamping generally does not generate chips and scraps, consumes less material, and does not require other heating equipment, so it is a material-saving and energy-saving processing method, so the cost of metal stamping parts can be well controlled.

The Detail Of BE-CU Metal Stamping Company

BE-CU.COM is a China based manufacturer offering Metal Forming services. Our plant specializes in Stamped Metal parts, post machining services and plating or painting. We press a comprehensive range of standard and complex custom shapes and some very challenging designs. With number of processes under one roof we manufacture all sort of products and offer assembly services.Your part drawings will be reviewed in house by be-cu engineers. The press will be designed around the profile according to the intended use for the metal part. Some design considerations, such as wall thickness, tolerances ant type of the metal may need to be taken into account. Off-tool samples will be provided to you after drawings are approved and tool been made.Our team of assemblers specialize in mechanical and electrical assembly of components. We are experienced with a large variety of assembly from simple one or two part additions to complete complex cabinets and assemblies. Additional services also include but not limited to Powdercoating, Plating, E-Coating, General Engineering and custom packaging.