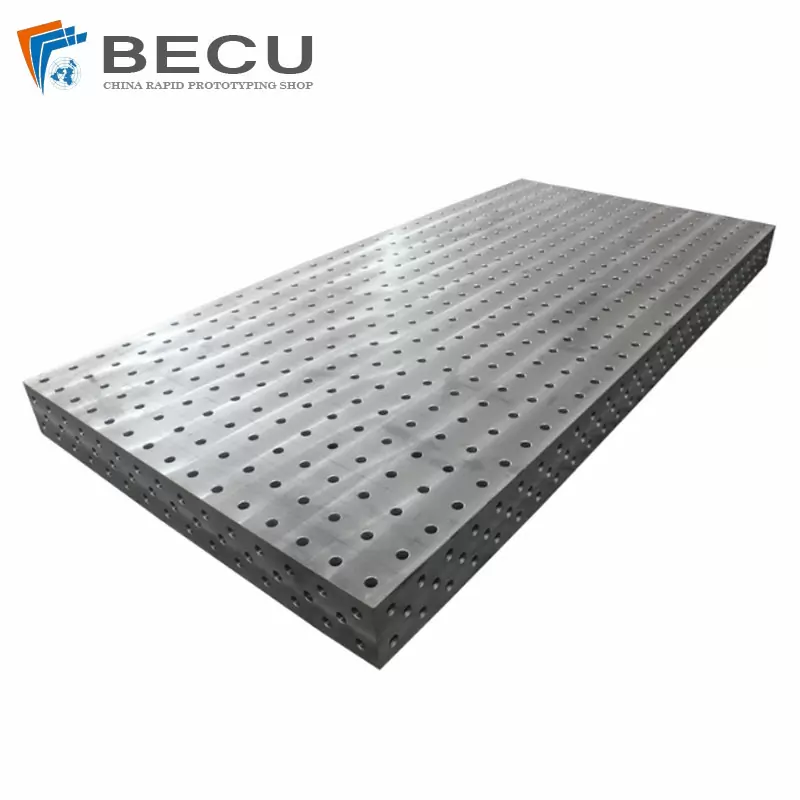

3D Flexible Welding Platform

- No.: Casting Iron

- Color: Custom

- Surface Treatment: Custom

- Product Material: Casting Iron

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Welding Platform

- Production Process: Large CNC Machining

- Size: According To Customer’s Drawings

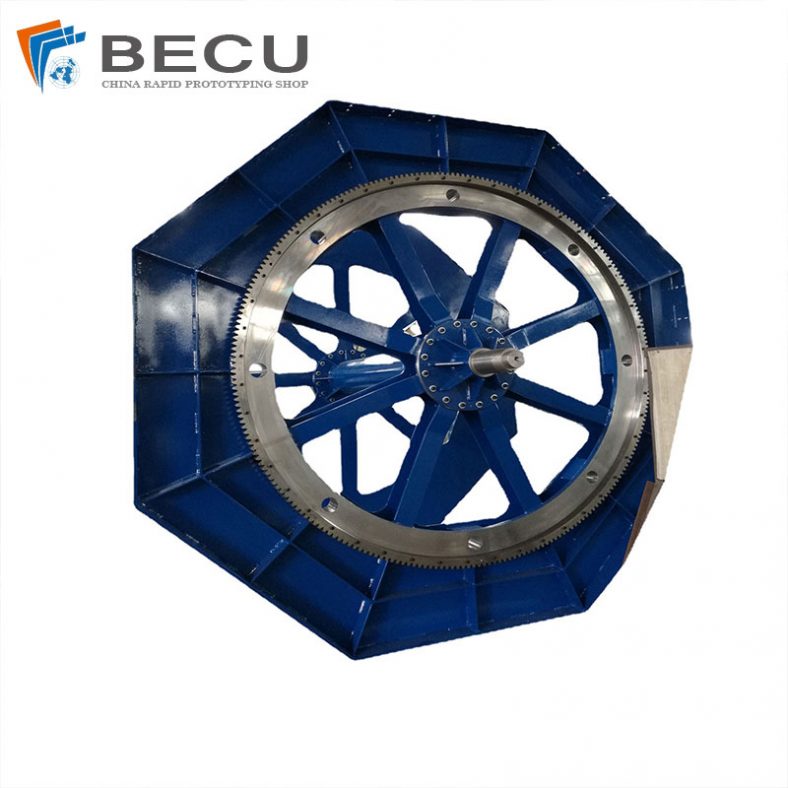

High-Quality Large Machining 3D Flexible Welding Platform

The flexible welding platform is widely used in equipment manufacturing and welding processing industries, completely changing the clamping and positioning method in the traditional industry, and promoting the generation of new process methods.Precision Large CNC machining and fabrication services for the sheet metal,welding, and other industries. Works with ferrous and non-ferrous materials. Capabilities include assembly, stamping, forming and casting. Low, medium and high volume production runs are available. Contact us for your 3d flexible welding platform.

The Features Of 3D Flexible Welding Platform

- Economy: The cost\time of one-to-one tooling invested in each product change can be almost no longer spent. The device is easy to operate and stable to use. Users can splicing out tooling with different requirements according to their needs and speed, just like children play with assembled toys.

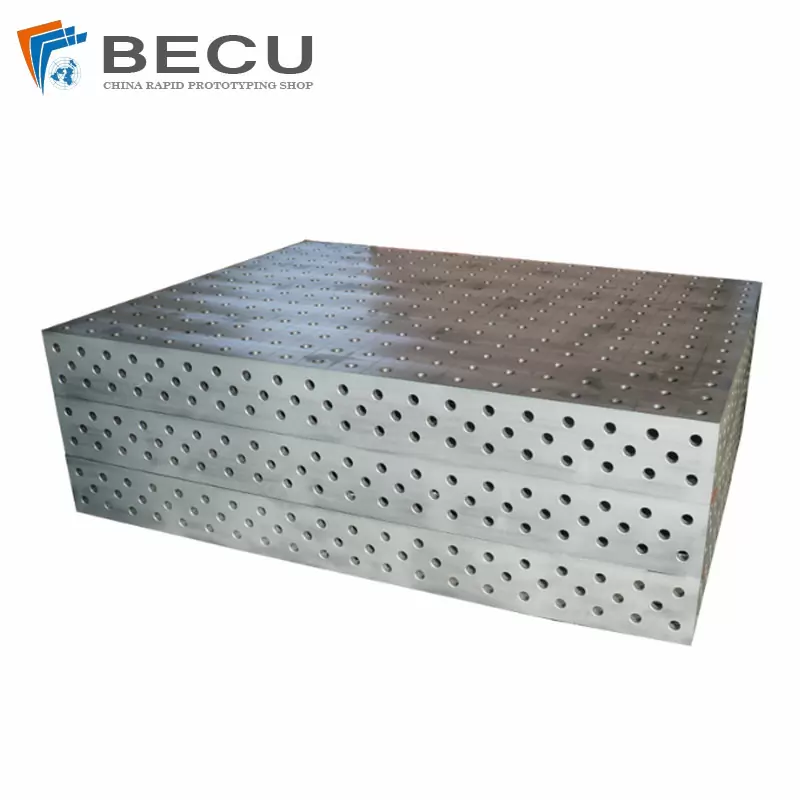

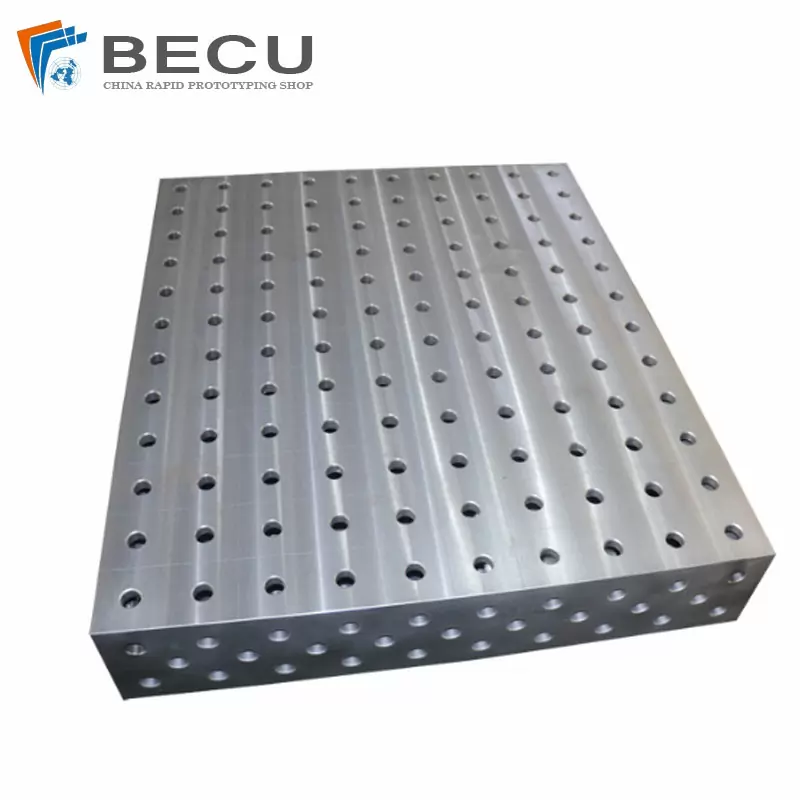

- Flexibility: The flexible welding platform has high bearing capacity and stable rigidity. Its five surfaces are machined with regular holes and engraved with network cables. The welding platform can be easily extended and extended, combined. The extended standard table tops can be connected directly together with modular positioning and clamping. In the process of installing, adjusting and positioning the workpiece, the general functions of the flexible three-dimensional combined welding tooling system are displayed with excellent quality, especially in the application of large workpieces. There are various assembling methods, as long as users give full play to their imagination, they can almost achieve the same positioning and clamping functions of any one-to-one fixture. The assembly speed is suitable, and the assembly and disassembly are convenient; the work surface can be assembled and combined according to the shape and size of the workpiece. The design of the scale and module size on the table allows the operator to build the required tooling according to the size and speed of the workpiece without measuring tools.

- Accuracy: Under the action of a concentrated load of about 2 tons and 1M2, the deformation amount of the flexible welding platform does not exceed 0.50mm, and under the action of a uniform load, the deformation amount is only 0.024mm, all of which can meet the needs of most welding. And the needs of assembly and processing, the accuracy of its assembly is acceptable, and the center tolerance of the positioning hole of the working platform is determined to be within 0.05mm. This high precision will be reflected in the products processed by the user, so this table can also be used as a reference platform for inspection tools.

- Repeatability: The table top of the flexible welding platform is composed of cast iron/steel structural parts/detailed processing parts/modular components, and its performance is very stable. Individual components can be replaced at little cost. The welding platform is specially processed. During the welding process, only low-cost anti-spatter liquid is needed to avoid welding spatter on the surface of the work table.

- Modularization: All components are classified into categories, standardized and serialized, and matched with each other. Selecting a few modules can realize the functions of positioning and clamping suitable for various speeds.

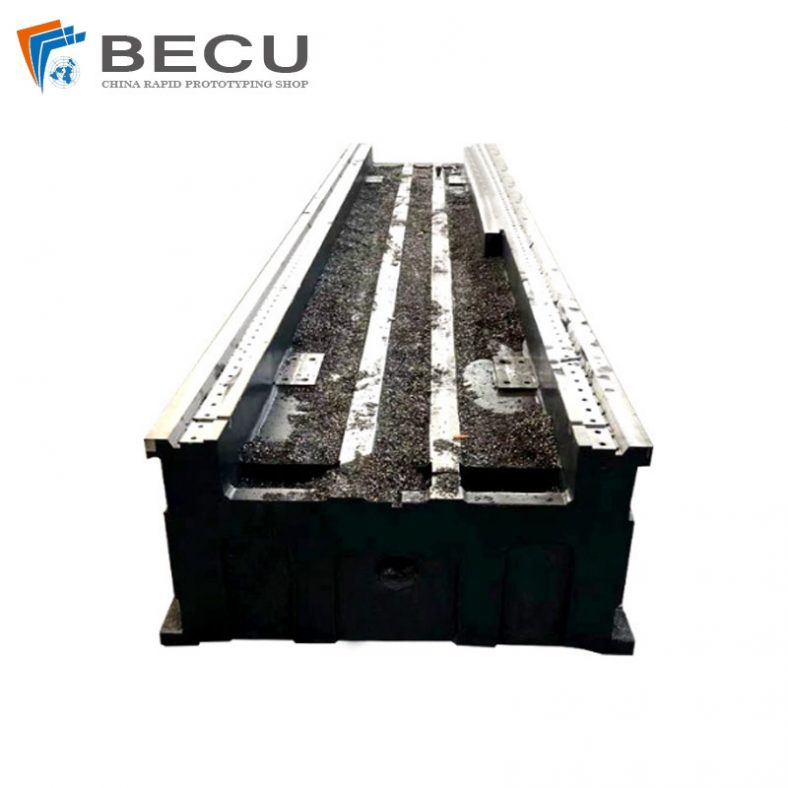

The Advantages Of Large Machining 3D Flexible Welding Platform

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Large Machining 3D Flexible Welding Platform

| Material | Cast Iron |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Welding Platform |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Prototype Company

At Be-cu.com, we provide large and heavy machining services for a vast range of industries. These industries may include niche sectors that require high accuracy, specialist, quality parts, and large part without sacrificing quality. Based on our experience and decades of professionalism, we can carry out large CNC machining projects in-house. This is done by taking them through the initial consultation to the cnc machining large parts as well as inspection of the final products.

If you are looking for a supplier of big size CNC machined parts, no match it is prototyping or volume order, we can make for you. Talk to us by today.