3D Printing Industrial Product Service In China

BE-CU is focused on industrial-grade 3D printing services, high-precision prototype customization accuracy is 0.016-0.1 layering, SLA laser rapid prototyping, prototype cnc machining, rapid customization of prototype models, prototype complex molds, etc., high-end SLA laser rapid prototyping, Germany Red wax machine printing, high-precision American machine printing, using photosensitive resin material with superior performance, similar to commonly used ABS material, waterproof and durable, high strength, high temperature resistance.

Industrial Product:Appearance design of electronic products, verification of mechanical parts, lighting modeling; hardware and other product prototypes

The Advantage Of 3D Printing Industrial Product

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient 3d printing china factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding 3D Printing Industrial Product Equipment

- P200 Industrial DLP 3D Printer

- ProJet MJP 5500X

- TPM ELITE P5000 SLS 3D Printer

- P480DL SLS 3D Printer

- ASM1500H SLA 3D Printer

- ASM-1200 SLS Molding Machine

- M400-4—SLM Metal 3D Printer

- DQ1200 FDM 3D printer

- Check Out BE-CU Equipment List

-

3D Printing Pool Pressure Cleaner Parts and Accessories

-

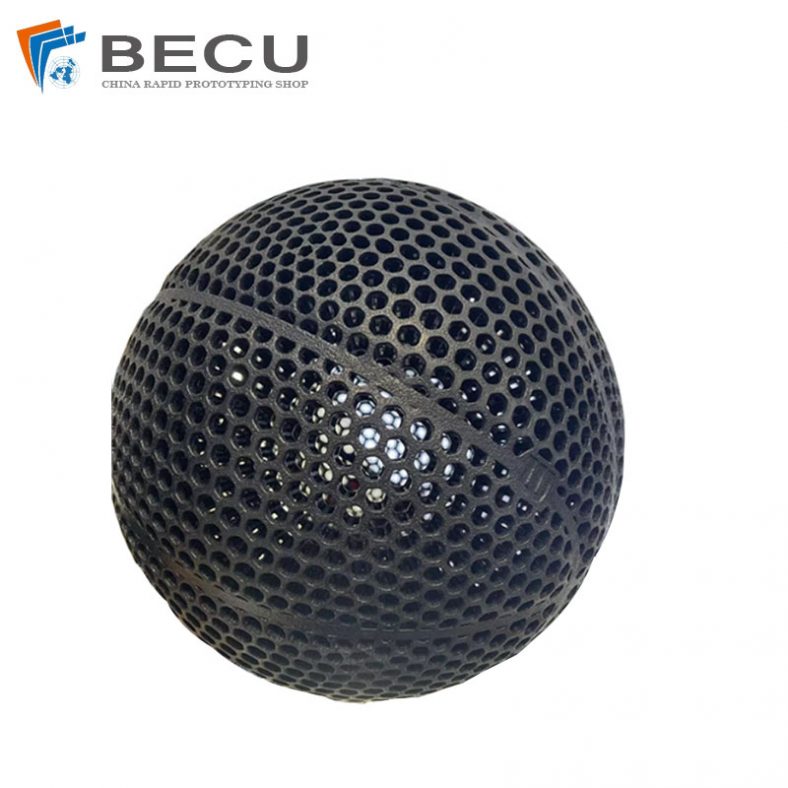

Nylon 3D Printed Size 5 Basketball

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

jetFusion 3D Printing Triceratops Mother and Child Sculpture

-

6061 Aluminum Alloy 3D Printing Black Dusting Parts

-

Development Resin Samples For Sports Shoes

-

3D Printed Sports Shoes Sole Model

-

Powder Sintering 3D Printed Shoe Midsole Sample

-

FFF Fused Wire Extrusion 3D Printed Pure Copper Parts

-

DLP 3D Printing DragonBall Dragon Desktop Ornaments

-

3D Printing Brown Wax Anime Doll

The Advantages Of 3D Printing Over Traditional Manufacturing

1: Manufacturing Complex Items Does Not Increase The Cost

As far as traditional manufacturing is concerned, the more complex the shape of the object, the higher the manufacturing cost. For 3D printers, the cost of manufacturing complex-shaped objects does not increase, and manufacturing a gorgeous complex-shaped object does not consume more time, skill or cost than printing a simple block. Manufacturing complex items without increasing costs will disrupt traditional pricing models and change the way we calculate manufacturing costs.

2: Product Diversification Does Not Increase Costs

A 3D printer can print many shapes, and it can make objects of different shapes every time like a craftsman. Traditional manufacturing equipment has fewer functions and can produce a limited variety of shapes. 3D printing eliminates the cost of training mechanics or acquiring new equipment, a 3D printer only requires a different digital blueprint and a new batch of raw materials.

3: No Need To Assemble

3D printing enables parts to be integrally formed. Traditional mass production is based on assembly lines, where machines produce identical parts in modern factories, which are then assembled by robots or workers (even across continents). The more parts a product has, the more time and cost it takes to assemble. The 3D printer can simultaneously print a door and the matching hinge above it through layered manufacturing without assembly. Omitting assembly shortens the supply chain, saving labor and transportation costs. The shorter the supply chain, the less pollution.

4: Zero Time Delivery

3D printers can print on demand. Just-in-time production reduces the physical inventory of enterprises, and enterprises can use 3D printers to manufacture special or customized products to meet customer needs according to customer orders, so new business models will become possible. Zero-time-delivery production minimizes the cost of long-distance transportation if the items people need are produced close by on demand.

5: Unlimited Design Space

Traditional manufacturing techniques and artisans produce products with limited shapes, and the ability to create shapes is limited by the tools used. For example, traditional wooden lathes can only make round objects, rolling mills can only machine parts assembled with milling cutters, and mold-making machines can only make die-cast shapes. 3D printers can break through these limitations, opening up huge design spaces and even making shapes that may currently only exist in nature.

6: Zero-Skill Manufacturing

Traditional craftsmen need several years of apprenticeships to acquire the required skills. Mass production and computer-controlled manufacturing machines have reduced the skill requirement, however traditional manufacturing machines still require skilled professionals for machine adjustment and calibration. 3D printers take various instructions from design files to make the same complex objects, and 3D printers require less operating skills than injection molding machines. Unskilled manufacturing opens up new business models and enables new ways of producing people in remote environments or extreme situations.

7: Does Not Occupy Space, Portable Manufacturing

In terms of unit production space, 3D printers are more capable of manufacturing than traditional manufacturing machines. For example, an injection molding machine can only make objects much smaller than itself, whereas a 3D printer can make objects as large as its printing table. After the 3D printer is debugged, the printing device can move freely, and the printer can make objects larger than itself. The high production capacity per unit space makes 3D printers suitable for home or office use as they require little physical space.

8: Reduce Waste By-Products

3D printers produce metal with fewer by-products than traditional metal fabrication techniques. The amount of waste in traditional metalworking is staggering, with 90% of raw metal being thrown away on the factory floor.Commercial 3D printing reduces waste when manufacturing metal. With the advancement of printing materials, “net shape” manufacturing may become a more environmentally friendly processing method.

9: Unlimited Combinations Of Materials

Combining different raw materials into a single product is difficult for today’s manufacturing machines because traditional manufacturing machines cannot easily fuse multiple raw materials together during the cutting or die-forming process. With the development of multi-material 3D printing technology, we have the ability to fuse different raw materials together. Raw materials that were previously unmixable are mixed to form new materials that come in a wide variety of shades with unique properties or functions.

10: Exact Solid Replication

Digital music files can be copied endlessly with no loss of audio quality. In the future, 3D printing will extend digital precision to the physical world. Scanning technology and 3D printing technology will work together to increase the resolution of morphological transformation between the physical and digital worlds, where we can scan, edit and replicate physical objects, creating exact copies or optimizing the original.