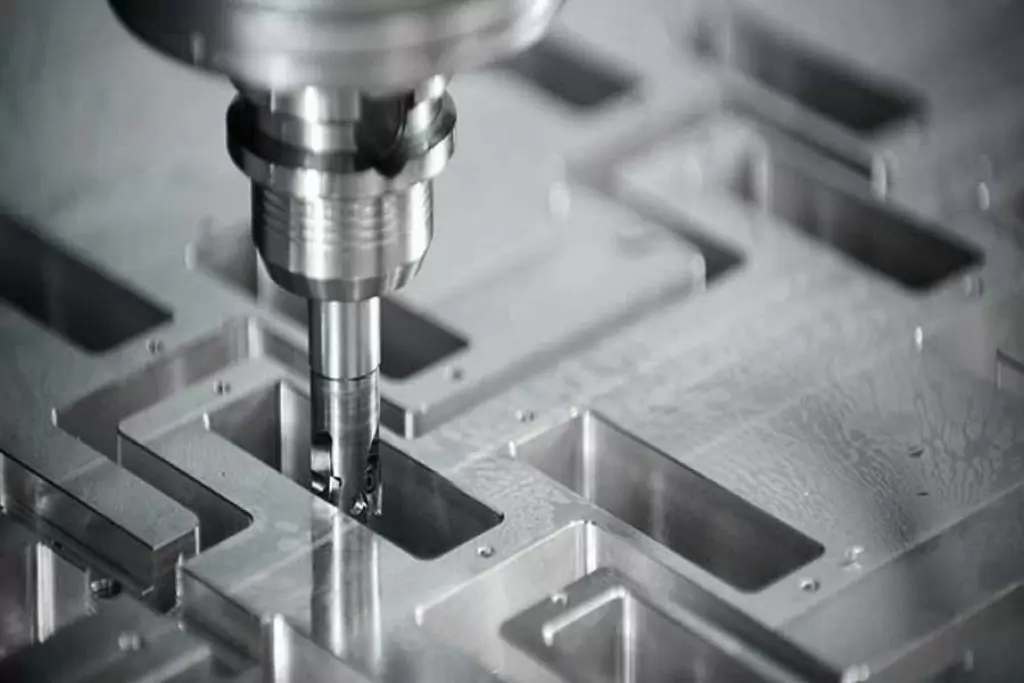

The wide application of CNC machine tools in production has allowed more and more processing companies to discover its advantages. Although China CNC machining tools are more expensive, many companies engaged in processing are still flocking to them, mainly relying on their efficient processing.

The efficient processing of the CNC system is mainly due to the advanced nature of the system, such as the automatic tool changing system, which effectively shortens the processing time to a certain extent and is very helpful in improving processing efficiency.

Principle Of Automatic Tool Change In Tool Magazine

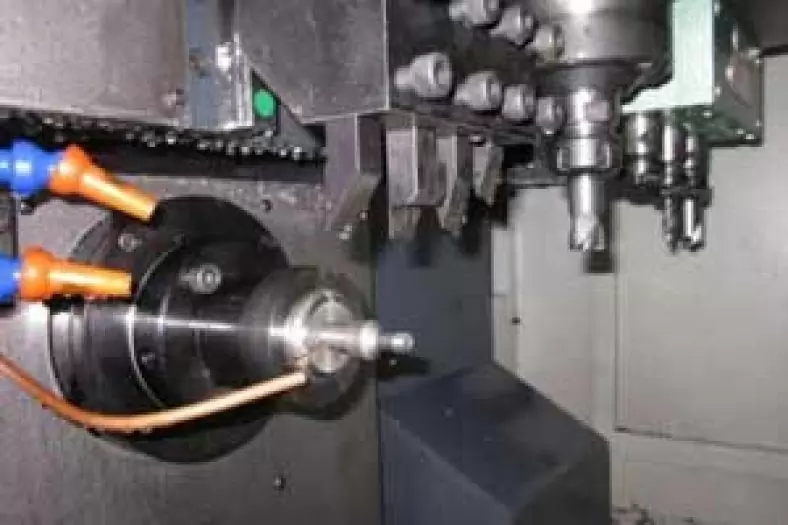

The tool magazine includes a tool sleeve rotating mechanism and a tool changing manipulator. The tool magazine is disc-shaped in shape and has an index plate inside. The rotary motion of the tool magazine is powered by a three-phase asynchronous motor with a holding brake. The three-phase power supply is supplied to the motor through the AC contactor. At this time, the holding brake is opened and the tool magazine runs. If the three-phase power supply is cut off, the holding brake is locked and the tool magazine stops running immediately.

Through the movement of the index plate and the logical combination of the related detection component groups, each tool pocket can be accurately stopped at the tool change position. After the tool holder stops at the tool change position, the cylinder controls the tool holder to be in a horizontal or vertical state to facilitate the manipulator’s tool change. The tool holder indexing table can rotate clockwise or counterclockwise, so that the tool to be replaced can be searched for in the shortest time.

The movement of the tool magazine tool-changing manipulator is also powered by a three-phase asynchronous motor with a holding brake. Through the gear transmission mechanism, the uniform rotational motion generated by the motor is converted into regular forward, stop, and rotational motions of the manipulator. The gear transmission is equipped with a micro switch set. This microswitch group is used to control the manipulator to clamp the tool, the manipulator to take the tool out of the spindle and tool holder, and the manipulator to be in the original position.

A torque limiter is built into the rotating tool holder of the tool magazine and the reduction transmission mechanism of the manipulator to prevent damage to the internal mechanical structure.

Specific Implementation Of Automatic Tool Change In Tool Magazine

The tool magazine manipulator is the main mechanism for realizing automatic tool change. Its task is to remove unused tools from the spindle and return them to the tool magazine after a process is completed. At the same time, it also loads the tools for the next process into the spindle, and then the manipulator returns to the original position to wait for the next work cycle.

The regular motion of the tool magazine manipulator is realized by three-phase asynchronous motors and gear transmission mechanisms, but these actions also need to be realized by the electrical system. The tool holder in the tool magazine moves to the tool changing position according to the instructions of the T code, and then the tool is exchanged. During the working process of the machine tool, the tool causes the robot to pick up or install the tool according to the instructions. Therefore, the electrical system is required to complete each action accurately and reliably according to the movement sequence of the tool change process.

Electrical Action Sequence

- Start tool selection, and the tool magazine rotates forward or reverse to find the nearest tool.

- The tool holder counting and indexing plate positioning signals stop the tool holder motor, and a tool holder stops accurately at the tool change position.

- The electrophosphorus valve that controls the flipping (vertical) movement of the tool holder is energized.

- The tool sleeve is in position vertically, sending out an in-position signal, and the spindle orientation gives a position arrival confirmation signal.

- The manipulator starts from the original position and rotates 90° to the manipulator clamping position.

- The manipulator snaps the tool in place and sends a stop signal, takes the tool out of the spindle and tool holder, and the manipulator motor stops.

- Confirm the tool buckle and release the tool to give the in-position signal.

- After the tool holder is relaxed, start the manipulator to rotate 180° to the tool replacement position.

- The robot motor stop signal stops the robot motor.

- Tool installation confirmation and tool clamping give in-place signals.

- The robot motor starts to return the robot to its original position.

- Robot motor stop signal to stop the robot motor.

- The original position switch of the manipulator sends a signal.

- The solenoid valve that controls the turning (leveling) of the tool holder is energized.

- The proximity switch that flips the set to the horizontal position sends a signal (the tool magazine tool changing action is completed).

The movements of the tool magazine and manipulator can be controlled by NC or PLC, depending on the actual processing conditions of the tool magazine.

The CNC machining center has an automatic tool changer, a tool changer and an automatic pallet exchange device. These devices can complete the processing requirements of different parts of the same workpiece as much as possible after one installation, and minimize the non-failure of the CNC machining center.

Downtime, to shorten the manufacturing cycle of the product, improve the processing accuracy of the product and other goals. The basic requirements for the automatic tool changer are mainly simple structure, reliable function, rapid exchange, and the tool exchange mechanism completes the exchange of the tool (new tool) in the tool magazine and the tool (old tool) on the spindle.

The performance of the automatic tool changer directly affects the processing efficiency. Although the types of tool magazines are different, the process of changing tools is the same. When the automatic tool changer receives the tool change command, the spindle stops rotating immediately and stops exactly at the tool change position, and the tool is released; the new tool moves to the tool change position with the tool magazine, and the tool is released; the double-arm manipulator moves the new and old tools At the same time, after the tool exchange table is rotated in place, the new and old tools are rotated on the spindle and the empty position of the tool magazine respectively; the spindle is clamped and returned to the original processing position to complete the tool change process.

The movement of the tool during tool change in the machining center consists of four parts; the tool stops with the spindle and moves to the tool change position, the movement of the tool in the tool magazine, the transmission movement of the tool with the tool change manipulator, and the movement of the tool back to the processing position with the spindle. Movement, etc., in which the movement of the tool and the chain in the chain tool magazine is the transfer pair, and the movement of the tool with the spindle is the moving pair.

The transmission motion of the tool changing manipulator includes both the rotating pair and the moving pair. The tool changing process of the tool changing manipulator is completed by the following five stages: the grabbing stage, the pulling stage, the tool changing stage, the inserting stage and the tool releasing stage.

These actions are completed by the following motion pairs; two racks and rollers and cylinders form a moving pair; two racks and two gear shafts form a gear pair; two gear shafts and the cylinder form a rotating pair; The robotic arm and the two gear shafts respectively form a moving pair, which moves back and forth to complete the action of drawing and inserting the knife.

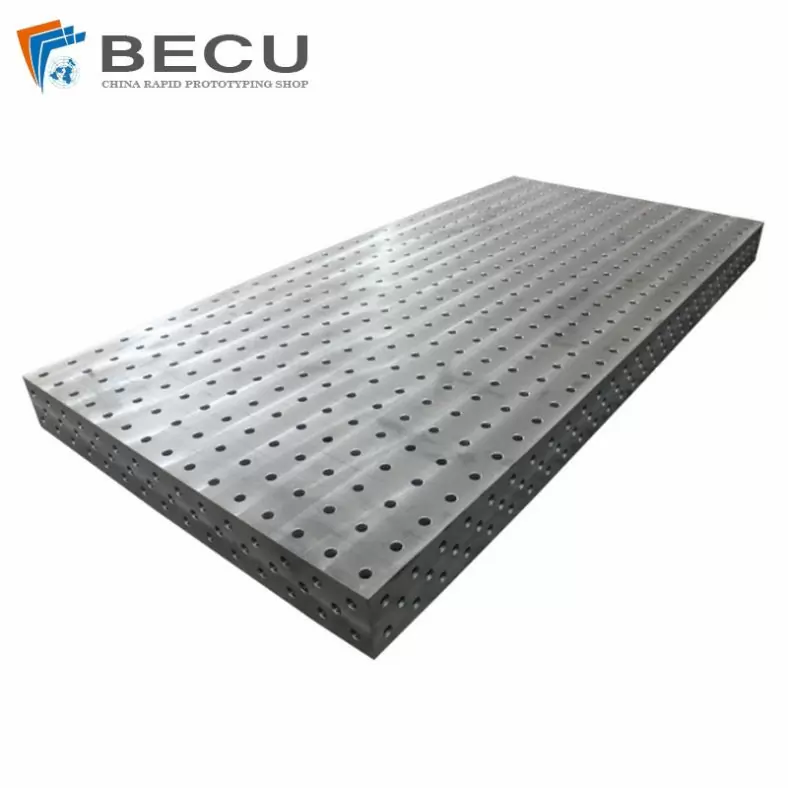

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]