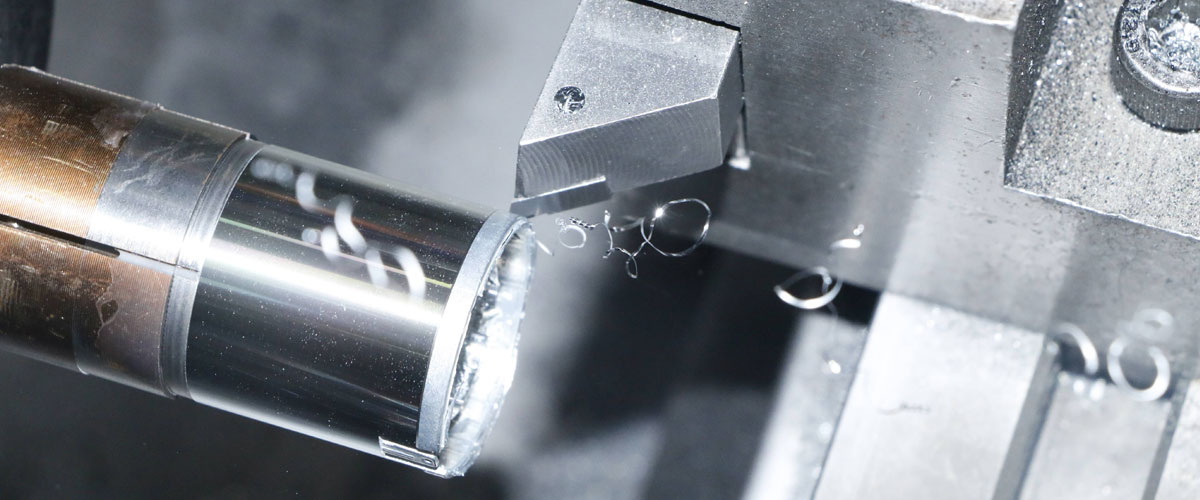

In the realm of precision manufacturing, CNC machining stands tall as a beacon of innovation and accuracy. As businesses around the world seek reliable and high-quality machining services, the choice of location becomes crucial. With its advanced technology, skilled labor force, and the status of being the world’s leading learn manufacturing country, usa has enticed global companies to establish factories in its growing region.

The precision CNC machining parts industry in usa has seen over 100 years of development. At the heart of USA CNC machining lies a tapestry of technological advancements and unparalleled expertise. The United States boasts a cutting-edge technological landscape, and this reflects in its CNC machining capabilities.

American manufacturers harness state-of-the-art machinery and tools, ensuring that each component is crafted with the utmost precision and efficiency. The expertise of skilled professionals further enhances the overall quality of CNC machining in the USA, setting it apart on the global stage.

This article aims to assist in identifying reputable CNC machining parts manufacturers in USA by highlighting the top 30 companies in the industry. These manufacturers are recognized for their well-equipped facilities, utilization of superior machining methods, and employment of experienced engineers. In the end, it also provides some guidelines to help you identify a reliable manufacturer for your CNC machining projects.

Overview of the Global CNC Machining Manufacturing Market

The CNC machining market has been witnessing steady growth due to increasing demand from various industries, including automotive, aerospace, healthcare, and electronics.The global CNC machining market is expected to reach over 46 billion USD by 2027, growing at a CAGR of 8.1% from 2024 to 2029.

This growth is driven by many factors, including:

- The adoption of Industry 4.0 practices, including the Internet of Things (IoT) and data analytics, can enhance the efficiency and connectivity of CNC machining systems.

- The market is populated by both established companies and smaller players offering specialized CNC machining services. Competition often revolves around technological capabilities, speed, and cost-effectiveness.

- The CNC machining market is expected to continue evolving with advancements in automation, artificial intelligence, and robotics. Integration with digital technologies is likely to be a key driver for future growth.

The global CNC machining market is witnessing many trends, including increasing demand for automation and robotics, growing adoption of additive manufacturing, and development of new materials and machining processes. However, the market is also facing challenges, such as rising labor costs, increasing competition from low-cost producers, and stringent environmental regulations.

The future of the global CNC machining market is expected to be driven by the continued demand for precision and complex machined parts, the growing adoption of CNC machining in various industries, and the technological advancements in CNC machines. The market is estimated to grow steadily in the coming years, with Asia Pacific being the fastest-growing region.

Why Choose CNC Machining Service Company in USA?

In the world of manufacturing, precision and efficiency are paramount. As industries evolve, the demand for high-quality, accurate, and intricate components is on the rise. This is where CNC machining services play a pivotal role. When it comes to choosing a CNC machining service company, the USA stands out as a hub for innovation and excellence. Let’s delve into the compelling reasons why opting for CNC machining services in the USA is a strategic choice.

- Cutting-Edge Technology:The USA is at the forefront of technological advancements, and this extends to CNC machining. Leading CNC machining service providers in the country leverage cutting-edge technology to ensure precision in every detail. From multi-axis machining to advanced tooling, these companies are equipped with state-of-the-art solutions.

- Skilled Workforce:A crucial element that sets CNC machining services in the USA apart is the availability of a highly skilled and experienced workforce. Machinists and engineers in the country undergo rigorous training, ensuring proficiency in operating CNC machines and programming complex codes. This expertise translates into the production of superior quality components.

- Quality Assurance Standards:The USA adheres to stringent quality assurance standards across industries. CNC machining service companies in the country comply with these standards, guaranteeing that the manufactured parts meet or exceed customer expectations. From material selection to final inspection, quality is embedded in every step of the process.

- Customization and Flexibility:Clients often require customized solutions to meet specific design requirements. CNC machining services in the USA excel in providing tailored solutions. The flexibility of CNC machines allows for the production of intricate and unique components with utmost precision, meeting the diverse needs of different industries.

- Quick Turnaround Times:Time is a critical factor in manufacturing, and CNC machining services in the USA understand the importance of quick turnaround times. Leveraging efficient processes and advanced automation, these companies can deliver high-quality components within tight deadlines, contributing to overall project efficiency.

- Innovation and Research:The USA fosters a culture of innovation and continuous research and development. CNC machining service providers in the country are at the forefront of adopting new techniques and technologies, ensuring that clients benefit from the latest advancements in the field.

- Global Competitiveness:With a reputation for excellence, CNC machining services in the USA contribute to the global competitiveness of industries. Businesses around the world choose American CNC machining companies for their reliability, precision, and commitment to quality.

In conclusion, choosing a CNC machining service company in the USA is a strategic decision driven by technology, skilled workforce, quality assurance, customization, quick turnaround times, innovation, and global competitiveness. These factors collectively position the USA as a premier destination for those seeking top-notch CNC machining solutions to meet the demands of the ever-evolving manufacturing landscape.

How to Choose the Right CNC Machine Shop in USA?

In the realm of manufacturing, the selection of the right CNC machine shop is a critical decision that directly influences the quality, accuracy, and efficiency of your components. With a myriad of options available, it’s essential to navigate the landscape wisely. This comprehensive guide sheds light on the key factors to consider when choosing the right CNC machine shop in the USA.

- Expertise and Experience:Begin your quest by assessing the expertise and experience of the CNC machine shop. Look for a company with a proven track record in handling diverse projects. An experienced shop is more likely to have encountered various challenges and developed effective solutions.

- Advanced Machinery and Technology:The backbone of any CNC machine shop is its machinery. Ensure that the shop is equipped with advanced CNC machines and technology. This includes multi-axis machining capabilities, high-speed machining, and the latest tooling options. State-of-the-art equipment contributes to precision and efficiency.

- Skilled Workforce:A skilled and knowledgeable workforce is instrumental in delivering high-quality components. Verify that the CNC machine shop employs experienced machinists and engineers who are proficient in operating CNC machines and programming intricate codes.

- Quality Control Measures:Quality assurance is non-negotiable in precision machining. Inquire about the quality control measures implemented by the CNC machine shop. This may include inspection processes, testing protocols, and adherence to industry standards. A commitment to quality ensures that the final products meet or exceed your expectations.

- Customization Capabilities:Every project comes with unique requirements. Choose a CNC machine shop that offers customization capabilities. Whether it’s complex geometries, tight tolerances, or specific material preferences, the ability to tailor solutions to your needs is a valuable asset.

- Turnaround Time and Efficiency:Time is often of the essence in manufacturing. Evaluate the CNC machine shop’s turnaround times and overall efficiency. A shop that can deliver precision components within reasonable timelines contributes to the success of your projects.

- Communication and Collaboration:Effective communication is key to a successful partnership. Opt for a CNC machine shop that values collaboration and maintains open lines of communication. A shop that understands your requirements and keeps you informed throughout the process fosters a positive working relationship.

- Industry Certifications and Compliance:Check for industry certifications and compliance with relevant standards. A CNC machine shop that adheres to quality and safety regulations demonstrates a commitment to professionalism and reliability.

- References and Reviews:Seek references from past clients and review online testimonials. Insights from others who have worked with the CNC machine shop can provide valuable information about their performance, reliability, and overall satisfaction.

- Cost Considerations:While cost should not be the sole determinant, it is undoubtedly a factor to consider. Request detailed quotes from prospective CNC machine shops, considering factors such as materials, complexity of the project, and additional services offered.

- In conclusion, choosing the right CNC machine shop in the USA involves a thorough assessment of expertise, machinery, workforce, quality control, customization capabilities, efficiency, communication, certifications, references, and cost considerations. By diligently considering these factors, you can forge a partnership with a CNC machine shop that aligns with your precision machining requirements and contributes to the success of your projects.

Top 30 CNC Machining Companies in USA

| Company Name | Region | Year Founded | Employee Size |

|---|---|---|---|

| Protolabs | Minnesota | 1999 | 50000-100000 |

| UNITED | Michigan | 1979 | 100-500 |

| METRO STEEL USA | Florida | 1914 | 500-1000 |

| Owens Industries | Wisconsin | 1944 | 500 – 1000 |

| Ardel Engineering | Minnesota | 1984 | 100-500 |

| RCO Engineering | Michigan | 1973 | 500-1000 |

| Jabil | Michigan | 1966 | 200000 |

| Summit CNC | Colorado | 2021 | 51 – 200 |

| Advance CNC | Ohio | 2002 | 500-1000 |

| Wisconsin Metal Tech | Wisconsin | 1994 | 500 – 1000 |

| Midwest Metal Products | Iowa | 1964 | 500 – 1000 |

| ESI Engineering Specialties | Connecticut | 1990 | 1000 – 5000 |

| BDE Manufacturing Technologies | Oregon | 2007 | 100-500 |

| Miller CNC | California | 2007 | 51 – 200 |

| Avanti Engineering | Illinois | 1972 | 500-1000 |

| Pioneer Service Inc. | Illinois | 1990 | 500-1000 |

| Cox Manufacturing | Texas | 1956 | 500-1000 |

| Machining USA, LLC | Florida | 1995 | 51 – 200 |

| Superior Joining Technologies | Illinois | 1998 | 500-1000 |

| Focused on Machining | Colorado | 2016 | 500-1000 |

| Micron Manufacturing | Michigan | 1952 | 500-1000 |

| PlasTex Precision | Texas | 1992 | 500-1000 |

| Swiss Technologies Inc. | Tennessee | 1924 | 500-1000 |

| American Micro Industries | Pennsylvania | 1936 | 500-1000 |

| Koss Aerospace | Ontario | 1975 | 1000 – 5000 |

| Decatur Mold Tool & Engineering | Indiana | 1966 | 1000 – 5000 |

| MW Industries | Texas | 1976 | 500-1000 |

| Cheetah Precision | Minnesota | 1980 | 100-500 |

| Intrex Aerospace | Colorado | 1974 | 500-1000 |

| ABS Machining | Ontario | 1971 | 1000 – 5000 |

Protolabs

Protolabs was founded in 1999 by Larry Lukis, a successful entrepreneur and computer geek who wanted to radically reduce the time it took to get injection-molded plastic prototype parts. His solution was to automate the traditional manufacturing process by developing complex software that communicated with a network of mills and presses. As a result, plastic and metal parts could be produced in a fraction of the time it had ever taken before.

- Over the next decade, Protolabs would continue to expand them injection molding envelope, introduce quick-turn CNC machining, and open global facilities in Europe and Japan.

- In 2014, we launched industrial-grade 3D printing services to allow product developers, designers, and engineers an easier path to move from early prototyping to low-volume production.

- And in 2017, we acquired Rapid Manufacturing to further expand our machining capabilities and introduce sheet metal fabrication into our suite of services. But that’s not all! Global online manufacturing platform, Hubs, also joined the Protolabs family in early 2021.

Our growth and expansion of capabilities over the past two decades has always been about providing you, our customer, with the best possible digital manufacturing experience in the industry. That continued evolution will never stop, and it’s what helps shape our vision and mission as a company.

UNITED CNC MACHINING

Located in Auburn Hills, Michigan UNITED CNC MACHINING, a Paravis Industries company, is a leading manufacturer of prototype and limited production CNC machined components as well as the tooling, fixtures, and gauges required for your in-house production. Our dedication to quality products, on-time delivery, and competitiveness guarantees United CNC Machining will be a valuable asset to your corporation.Industries:

- Aerospace

- Defense

- Medical

- Transportation

- Naval

- Automation

- Alternative Energy

- Optics

- Off-Road / Petroleum

United CNC Machining combines the latest machining technologies with highly skilled machinists, responsive customer service and creative innovation to meet even the most stringent requirements. Understanding today’s compressed delivery requirements, we have supercharged our facility with more than 30 CNC centers to immediately launch your projects and beat our competition to your receiving dock with machined parts that exceed your expectations.

As quality can never be jeopardized, we adhere to the stringent requirements of ISO-9001 and AS9100.

METRO STEEL USA

At Metro Steel USA, our unwavering dedication to customer satisfaction forms the very core of our mission. With an unrelenting commitment to excellence, we continually strive to deliver high-quality components and products with unwavering punctuality, all with the express aim of ensuring the utmost satisfaction of our valued customers. Quality is not just a mere consideration; it is an integral part of our organizational philosophy, woven into the fabric of our operations. Our management team stands as a paragon of dedication, resolutely focused on the relentless pursuit of continuous improvement in both our products and services. This pursuit is guided and fortified by a comprehensive framework of risk management and change management policies and procedures, ensuring that we remain agile and responsive in an ever-evolving marketplace.

As we fast forward to the present, the ownership of Metro Steel has been in the capable hands of Bryan Shepherd since 2001. Under his guidance, the company has experienced remarkable growth in both size and capabilities. The integration of advanced CNC technology, such as Laser, Plasma, Press Brakes, Machining, and more, has further expanded our ability to provide value-added processing solutions. Located in Tavares, Florida, Metro Steel USA now stands as a formidable presence with a sprawling 200,000-square-foot facility.

Owens Industries

From its inception in 1944 during the war efforts to the present day, Owens Industries, Inc. continues to excel in the CNC machining of very tight tolerance, ultra-high precision components. Based in Oak Creek, WI, we have developed a reputation for quality and reliability, we have a growing list of references who trust Owens, and Owens alone, with their every CNC machining need. We provide the highest quality CNC machining services including:

- 5-Axis Work

- Precision CNC Milling with 3 and 4-Axis Work

- Ram/Sink/Plunge EDM

- Wire EDM

- Micromachining

- CNC Lathes/Turning

- Deburring

- Limited Grinding

Our facility was specially designed and constructed for our ultra high-end machining processes, utilizing temperature and dust control systems to ensure each component we machine can meet the exact specifications of the project. Specializing in the ultra-precision CNC machining of complex and precise components, we machine the parts “normal” machine shops may find “impossible” to achieve.

The CNC professionals at Owens Industries offer a wide variety of services for businesses just like yours, and our ultra-precise CNC Swiss machining is top-of-the-line and offers quality precision parts at the most affordable prices. Our Tornos Swiss machining lathes are operated by our CNC professionals, ensuring your parts are manufactured precisely, accurately, and with the tightest tolerances.

Some of the industry-specific applications we use CNC Swiss machining for include:

- Aerospace electronics and instrumentation

- Optical measurement components

- Medical and Surgical tools and devices

- Guidance systems

- Watch industry components

- Micro Computer fittings and connectors

- Robotic mechanisms

- Fuel systems

- Defense systems

Take a controlled machining environment, pair it with highly capable staff and industry-leading equipment, and the result is a CNC machine shop with unbeatable capabilities in our field of service. Beyond Owens Industries facility’s controlled environment, we have a highly skilled team of people and industry-leading machines giving us, and your company, an upper hand in the production of all components. Our machinists are teamed up with the best German and Swiss companies to develop specially calibrated 5-Axis Machining Centers and 5-Axis Wire EDM for your unique needs. Our engineers have worked with a Swiss EDM manufacturer and a Japanese support systems manufacturer, to integrate a specially developed 5-axis system capable of achieving unparalleled accuracies – precision calibrated and aligned to achieve absolute perfection. Aside from collaborative work with our employees, our equipment contributes to our success.

Ardel Engineering

During that time, Ardel has been presented with many challenges across a broad spectrum of customers and industries. These challenges and their solutions have all helped to propel Ardel to a reputation for Quality, Delivery, Reliability, Efficiency, Confidentiality, and Partnering.

Ardel’s philosophy from day one has been to support our customers in building their product. Whether it is a component or a product subassembly, Ardel is constantly adding new equipment to improve the quality and efficiency that is needed to compete in today’s marketplace. It is our goal to exceed our customers’ expectations. By finding the best employees and using the latest technological improvements this goal can be met.

Ardel is certified to the latest international quality management system, ISO 9001:2015. Under this certification, Ardel is able to offer its customers total control of material and processes. With the latest CMM and other measurement instrumentation, verification and documentation becomes standard.

Ardel uses electronic data communications throughout the organization. From e-mails, to drawings, to purchase orders, to payments, Ardel has become fully paperless with some customers. Some customers have even requested to use credit cards for project management and cost control.

RCO Engineering

From the early days onward, RCO has earned trust from the automotive industry’s leading brands. By the mid-1980s, we were a go-to partner for automotive engineering, prototyping, and product development services with particular expertise as one of the leading automotive seat manufacturers. As client needs grew, we expanded our capabilities and offerings. This led to important roles within the aerospace design industry as well as the defense industry.

Today, our employees find that RCO operates under the same values that Paul Sr. had when he started the company. These values eventually formed the basis for RCO’s operating philosophy. Emphasis is placed on teamwork and respect for our employees. These values, along with our never ending quest to provide our customers with excellent quality, service, and value will ensure that RCO Engineering, Inc. will be a competitive force well into the 21st Century.

Jabil

Jabil is a global manufacturing company with more than 200,000 employees across 100 locations in 30 countries. We’re big; but we’re not a household brand because most of what we make is for our customers. That list includes 300 of the biggest brands in the world in every market from healthcare, packaging, smartphones and cloud equipment to automotive and home appliances.

At Jabil, we strive to make ANYTHING POSSIBLE and EVERYTHING BETTER.

We combine unmatched breadth and depth of end-market experience, technical and design capabilities, manufacturing know-how, supply chain insights, and global product management expertise to enable success for the world’s leading brands. We are driven by a common purpose: to make a positive impact for each other, our communities and the environment.

Summit CNC

Summit CNC (formerly Precision Parts Fast) is an ISO 9001:2015 compliant prototype and low volume precision CNC machine shop located in the Denver, Colorado area. We are dedicated to servicing the prototype and low volume production needs of our customers, which primarily consist of mechanical engineers and purchasing agents from OEMs and engineering firms in Colorado and the western United States. The company’s specialties include tight tolerance machining of hard metals such as stainless steels and titanium, soft metals like aluminums and coppers, and plastics. Our owners and operators, Jason Korbelik and Brian Korbelik, come from a 3rd generation manufacturing family. Not only do Jason and Brian oversee the day to day business operations at Summit CNC, they are also both CNC machinists. This benefits our team and our customer because they know exactly what goes into machining your parts!

Advance CNC

Advance CNC is a high volume production machine shop located in Central Ohio serving American manufacturers across the United States. Our facilities in Grove City and Cincinnati Ohio are equipped with 24/7 automation technologies and specialized tooling that help to solidify Advance as the experts in aluminum machining.

Our high-speed CNC machines, high-tech tooling, and super-fast spindle speeds allow us to machine your parts at much faster speeds and with greater accuracy than ever before. For your convenience, we offer 4-axis, 5-axis, and Swiss CNC machining capabilities at our Columbus and Cincinnati, Ohio, machine shops.

Our expertise in high speed 4-Axis & 5-Axis aluminum machining has made us the largest machine shop in Central Ohio and one of the most trusted machining companies across the United States.

In every job we do, we strive to be easy to work with. Whether it is running lights out to achieve faster lead times, or utilizing our stocking program for blanket orders

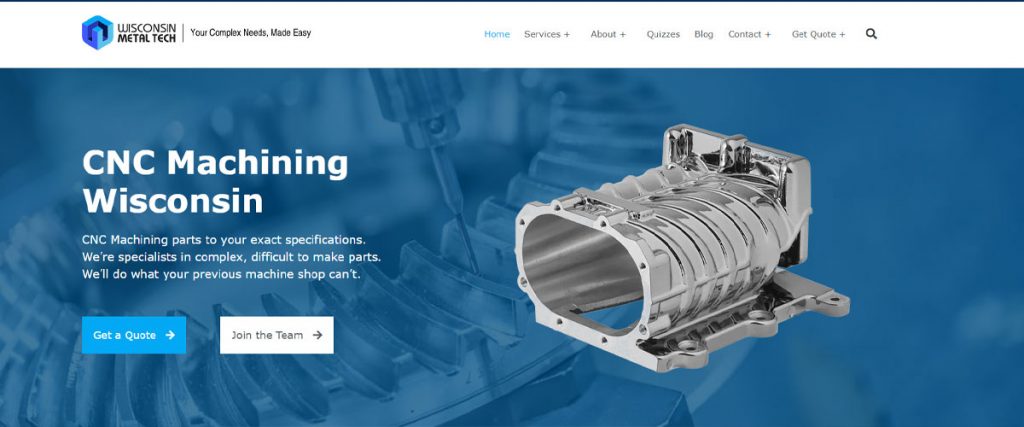

Wisconsin Metal Tech

At Wisconsin Metal Tech, we serve a wide range of customers including original equipment manufacturers and contract part and assembly providers across the Midwest, nationwide, and the world with CNC Metal Machining.

We offer various services to meet our customers’ diverse needs.

Some rely on us solely for rod and bar supply, while others take advantage of our value-added secondary services such as sawing, heat treating, plating, or grinding.

- Rapid Turnaround Time: We understand that time is of the essence for our customers, and that’s why we prioritize rapid turnaround times for on-demand parts.

- Elimination of Variation: We pride ourselves in our ability to eliminate variation and maintain lot-to-lot quality, reducing the need for on-site inspection.

- Cost Reduction: Our track record for cost reduction is another reason why so many customers return to us.

- Reliable Quality: We maintain reliable, lot-to-lot quality on our CNC metal maching to eliminate the need for on-site inspection.

- Single-point Project Management: Our single-point project management approach ensures accountability and control throughout the entire process, from initial estimate to delivery.

Customers return to Wisconsin Metal Tech for our commitment to speed, accuracy, and expertise in CNC metal machining, grinding, and other related services.

Our state-of-the-art technology, highly skilled team and commitment to quality set us apart from the competition.

Trust us to meet your metal machining needs on time, on budget, and to the highest standards.

Midwest Metal Products

Located in Cedar Rapids, Iowa, Midwest Metal Products has been a leader in the metal fabrication industry for over 55 years. Our commitment to quality, service and on-time delivery is paramount – every order, every time.

Our manufacturing facility has the most advanced processes and technology to continually meet industry standards, producing products that exceed our customers’ goals.

Starting with the most detailed part, Midwest Metal Products programs all dimensions directly into our CNC equipment. And throughout the manufacturing process, each job is monitored by Statistical Process Control (SPC)-trained employees to maintain efficiency and accuracy.

ESI Engineering Specialties Inc.

At ESI, we understand the worlds where our customers work. For more than three decades, we’ve built our company on delivering a new level of engineering solutions and manufacturing services, including the latest automated systems. In fact, a major part of our experience comes from serving automotive clients with safety-critical parts—one of the most quality, time and efficiency-driven industries in the world.

We’ve designed an automated assembly machine that simultaneously inspects every part for 10 criteria, using advanced vision technology. Built for a unique seat-belt application, this system is just one of the technologies we’ve created to meet precise specifications. Fully automated, it eliminates labor costs. Inspecting every single part, backed by Six Sigma Black Belt Trained QA personnel, ESI takes quality assurance to new heights.

BDE Manufacturing Technologies

BDE Manufacturing Technologies (BDE) is a state-of-the-art CNC machine shop in Beaverton Oregon, about 15 miles west of Portland Oregon. We are a full service organization that provides a wide variety of support for our clients. This includes preproduction consulting and planning, design services, tooling, prototyping, production, and assembly capabilities.

BDE’s senior staff has an average of 20+ years’ experience in the manufacturing arts with skills in many different disciplines. The average length of service at BDE is over 12 years. Our staff is fully supported with 2 seats of Autodesk Inventor 2016 and 10 seats of Mastercam 2017 on the latest Intel based multi-core work stations. Our new modern 35,000 sq. ft. facility is equipped with cutting edge server and networking technologies powered by a 5 server rack-mounted array.

BDE has implemented Global Shop Solutions as our Enterprise, Resource, Planning tool (ERP Software). This software controls the entire shops activities from CRM through Quoting, Order Entry, Purchasing, Shop Floor Control, Quality Control, Gathering of labor and material costs, Routers, Work Orders, Inventory control, Shipping and receiving, and all of the Accounting Functions(A/R, A/P,P/R).

Our shop floor staff is fully supported with a state of the art tool management system that is integrated with our supplier’s database. This system maintains all tooling that is used by the machine tool. This insures that “best in class” tool holding and cutting tools are always available to assist our machinists in their craft.

Our founder, Bob Hale, has a strong “can do” philosophy which he has infused throughout the company. By bringing all parties together to focus on solutions, BDE has built a strong reputation for helping customers fulfill their manufacturing needs. This philosophy is the driving force behind the constant evaluation and implementation of new technologies. Our people are always pushing the envelope for better and faster methods. As a result, BDE has developed a very strong and diverse manufacturing capability. Our staff is fully capable of designing and building all types of tooling, fixtures, prototypes, short run production, and just about anything else that requires precision craftsmanship.

Our customer base has grown dramatically over the last decade and stretches far beyond our immediate area, including but not limited to: Hillsboro, Beaverton, Portland, Tigard, Tualatin, Wilsonville, Forest Grove, Newberg, McMinnville, Gresham, Clackamas, Vancouver, Corvallis, Eugene, Tacoma, Seattle, Spokane, Boise, Palo Alto, San Diego, Tucson, Green Bay, Singapore, The Netherlands, Sweden, and Israel.

Miller CNC

Our Vision is to continuously advance the limits of human and technological innovation.

Our Mission is to reliably provide mission-critical metal parts to world class manufacturers who are solving the world’s most challenging problems.

Our Core Values:

- We are reliable

- We embrace growth

- We simplify complex work

- We are problem solvers

- We have high standards

Miller CNC, located in San Diego, California was founded in 2007 as a small family-owned business with just two CNC mills and a CNC lathe. Initially, Miller CNC offered CNC machining services to local San Diego companies that operated businesses in industries from off-road racing, underwater rovers, surgical equipment, and everything in between. In 2009 Todd Cuffaro, the company’s current President and the sole owner sold the assets of his off-road racing business and purchased a majority stake in Miller CNC. The first objective was to find a niche in which Miller CNC could become an industry leader. Based on the technical expertise of the team, the clear path was to focus on CNC machining hard metals, exotic alloys, 5 Axis Milling, and complex parts. This led to the company obtaining AS9100 and ISO9001:2015 certification in 2010, acquiring more equipment, and building a larger team. Miller CNC has experienced double-digit growth nearly every year since 2009 and is now an industry-leading full-service CNC machine shop serving customers in the aerospace, defense, space, energy, medical and industrial manufacturing industries.

We believe that in order to support our customers’ missions we must continuously improve our capabilities, which requires significant investment in talent and technology. Miller CNC is dedicated to developing the best team possible and empowering our team to perform their best work. This has led us to purchase some of the industry’s most capable CNC Mills, CNC Lathes and QC inspection equipment, develop a robust AS9100 and ISO9001:2015 certified Quality System which includes companywide utilization of Shoptech E2 ERP system, and perhaps most importantly, constantly train and develop our team.

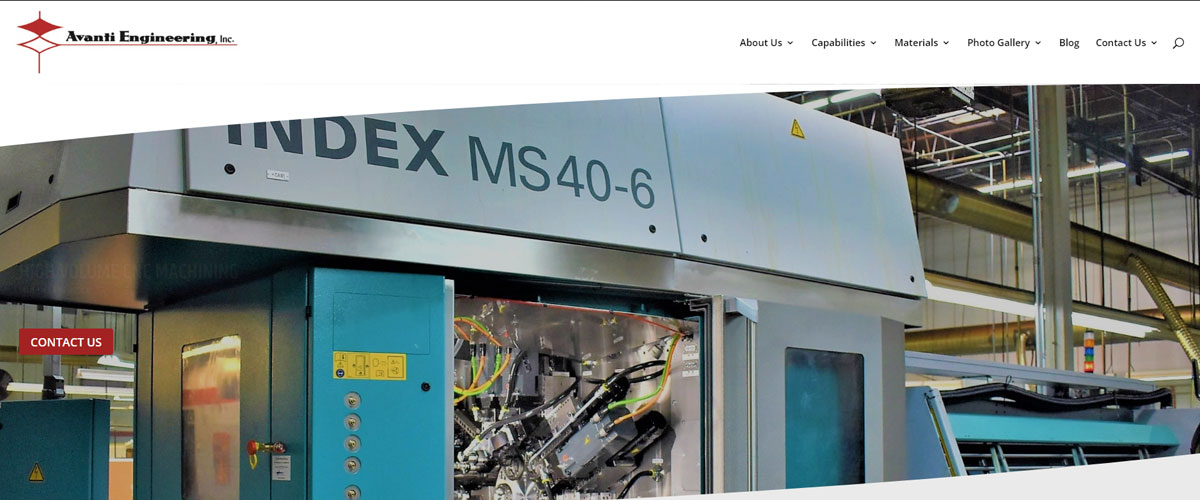

Avanti Engineering

‘Avanti’ translated is Italian for ‘move forward’ and moving forward is exactly what Avanti Engineering, Inc. has been doing since 1972. Founder and CEO Joseph J. Bratta began in a small garage-based operation on a Davenport. His philosophy of superior service combined with quality machine parts and competitive prices are just a few of the ways in which Avanti Engineering sets itself apart from the competition. Established in 1972 by CEO and founder Joseph J. Bratta, Avanti Engineering, Inc. is a family-owned business that’s committed to providing high-quality, precision-machined parts at affordable prices. The operation started as a small garage-based operation based in Davenport; it rapidly grew and matured into the Avanti Engineering of today.

“From day one, our philosophy has been to blend superior service with quality work and competitive prices. This has been our unwavering attitude,” Bratta explained. He attributes the company’s success to the collective emphasis on customer satisfaction. Today, Avanti Engineering operates out of a 55,000-square-foot facility, located in the Chicago area..

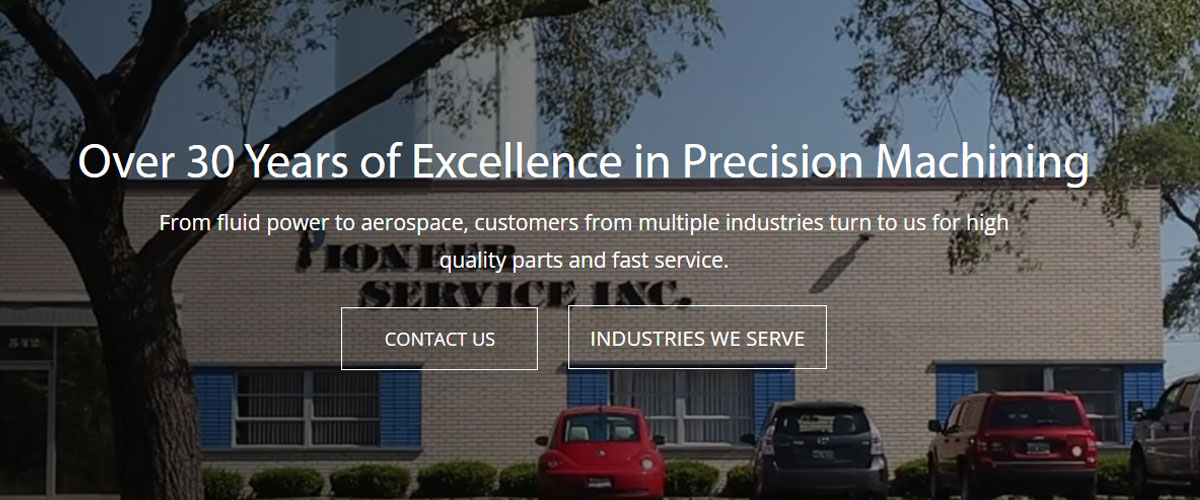

Pioneer Service Inc.

In 1990 Pioneer Service started with a few Brown and Sharp screw machines and Centerless grinders, and a team intent on developing a precision machining business that delivers top quality turned parts.

Over 30 years later, that mission is our purpose and vision.

Pioneer Service continues to deliver quick turn-around for precision Swiss machined parts and centerless grinding services. We serve a vast number of industries including: Medical, Aerospace, Electric Vehicles, Hydraulics, Motion Control, Oil & Gas, Sporting Goods, Food Equipment, Lawn and Garden and many others.

Our team takes pride in building long-term relationships with our clients by continually supplying them the highest quality parts with reliable, on-time delivery.

COX Manufacturing

Being a 67-year-old, third-generation screw machine products company, Cox Manufacturing understands that customers expect high quality parts delivered on time and at competitive costs. We have continually invested in our shop floor technology and our people. With these investments and thirst for “Continuous Improvement”, we are one of the finest production machining facilities in the United States and numerous auditors have stated as much.

- Today, we employ 190 people and are growing still.

- We have one of the best Work Force Development programs in our industry with an Apprenticeship Program certified by the Department of Labor.

- We schedule approximately 100 primary machines – 270 spindles – to produce across 3 shifts.

- Every week, we produce and ship over 1.7 million precision components to diverse industries coast to coast.

Machining USA, LLC

Machining USA is the premier CNC job shop in the the Southeastern United States. The company handles production runs of all sizes and is dedicated to delivering unmatched American quality. With over 29 years of industry experience, the company offers unparalleled value to the production process to assure optimal production quality. Machining USA reduces delivery time and costs, without compromising quality, by implementing proprietary production methodologies.

Superior Joining Technologies, Inc.

Superior Joining Technologies, Inc. (SJTI) has grown and developed into a highly technical and precise welding operation serving any industry that needs that level of expertise and documentation, most notably aerospace. We work to support our customers, grow each employee and then reach out to have a positive impact on our community—especially as it pertains to supporting the manufacturing industry as a whole.

Originally, the name Superior Joining Technologies, Inc. (SJTI) was created to emphasize our core competency in Precision Welding (defined as joining, or uniting, metal parts…), focusing on our commitment to high quality machinery, close tolerance tooling and fixtures and an adherence to industry standards by gifted and disciplined craftsmen.

Throughout the past twenty-five years, we have built relationships and earned the trust of our customers by joining with them in solving design issues, developing new products and forming flexible manufacturing networks to provide complete solutions. By joining multiple processes within our 55,000 sq. ft. facility, we have reduced lead-time to our customers and have greater control of cost fluctuations. Through the power of partnerships, we have joined with various providers of high quality processes and products successfully raising the level of quality compliance and reducing costs.

We have an expressed desire to see our employees succeed. Our organization has joined with them to encourage continuous education by offering tuition reimbursement which has enhanced both professional and life skills. We also offer eight hours of paid community service on an annual basis to all full-time employees.

With a passion for the education of our communities’ youth, we are continually joining with schools, service organizations and trade associations in and around our area to contribute to their goals of enriching the life experience of students and providing exposure to the rewarding world of manufacturing.

Focused on Machining

I began my professional career in the Air Force where I spent 6 years as an Aircraft Mechanic on the C-17. As a flight mechanic I traveled the world with a toolbox and a laptop and ensured the aircraft remained operational in obscure locations like Afghanistan, Iraq, and even Antarctica. I separated from the Air Force to pursue a Bachelor’s degree full time at the University of Northern Colorado, where I graduated with honors from the Monfort College of Business with a Bachelors degree in Business Administration with an emphasis in Finance. After graduation I did a few internships in finance but ended up with Centennial Bank where I worked for over five years as a Commercial Banker.

While working at the bank I also attended the University of Colorado at Denver where I received my MBA. With a strong interest in manufacturing, in 2016, I acquired Focused on Machining. Currently the President of Focused on Machining, I manage the day-to-day operations, business development, and strategic planning for the business. Since I’ve owned the company, we’ve grown over 300% in the last four years with the addition of many new customers and pieces of equipment. Our primary growth sectors have come from the aerospace, defense and medical industries. Focused on Machining continues to seek growth opportunities with both new and existing customers.

Micron Manufacturing

Since 1952, Micron Manufacturing Company has grown from its humble beginnings as a screw machine shop to an award-winning leader of precision machined components. Micron can provide simple to highly technical parts, made from a variety of materials such as aluminum, brass, bronze, copper, plastics, stainless steel, and steel.

Today, Micron serves a variety of industries with a wide range of CNC machining capabilities that include:

- Turning

- Milling

- Light assembly

- Design for manufacturing

- Prototyping for production

- Inventory management

Micron has established partnerships to provide additional services, including:

- Grinding

- Plating

- Heat treating

- Finishing

Micron builds their customer relationships from the beginning with the quoting process. It starts with a feasibility process with engineers that specialize in design for manufacture, and continues through implementation of your part to production. Design and engineering support, along with the best machinery available, results in quality parts, on time, on budget, for all sizes and complexities.

PlasTex Precision

At PlasTex Precision, our highly skilled staff brings a unique set of versatile talents to the CNC machined plastics market. Spanning more than 35 years of combined experience, our backgrounds include engineering plastics fabrication, manufacturing, distribution, applications analysis, and field level sales. This diversity of experience gives us distinct competitive advantages that include:

The employment of best practices in every facet of the PlasTex Precision operation. From initial introduction until your parts ship out the door, PlasTex Precision has proven processes that ensure you receive the right material, made into the right parts, all within the right timeframe.

A unique capacity to create effective solutions for our customers when faced with challenging applications. While other operations will simply “no quote” your project when out of their scope, our sense of urgency coupled with industry experience drives us to work alongside our customers until an effective solution is found.

The ability to partner with you from the inception of an idea all the way through the manufacturing process. Our years of field applications knowledge can assist you in product development and carry you into prototype and testing. PlasTex Precision will then work to adjust if necessary until the desired prototype results are reached. Finally, we move with our customers to the production phase where our manufacturing expertise delivers the right product at the right time.

Extensive competencies in Mastercam programming designed to reduce lead times, CAD drawing capabilities, custom in house tool-making to meet your project needs, and wide-ranging reverse engineering capabilities.

Our select group of employees was brought together for one reason: To bring the engineering plastics fabrication world to a new level of customer service, professionalism, and dependability. At PlasTex Precision, we stand ready and capable to become your total CNC machined plastics partner.

PlasTex Precision Manufacturing is headquartered out of Houston, Texas. We are proud to be Texans, but we are even more proud of the clients that we serve locally, throughout the United States, and around the globe. Our clients have come to depend on reliable, precise, and timely turn-around on their products. Our growth comes from customer referrals and we strive to ensure that our clients are more than pleased to recommend our services to others. Give PlasTex Precision a call about your next CNC plastic machining project and discover for yourself why we are so much more than “just another plastics machine shop”.

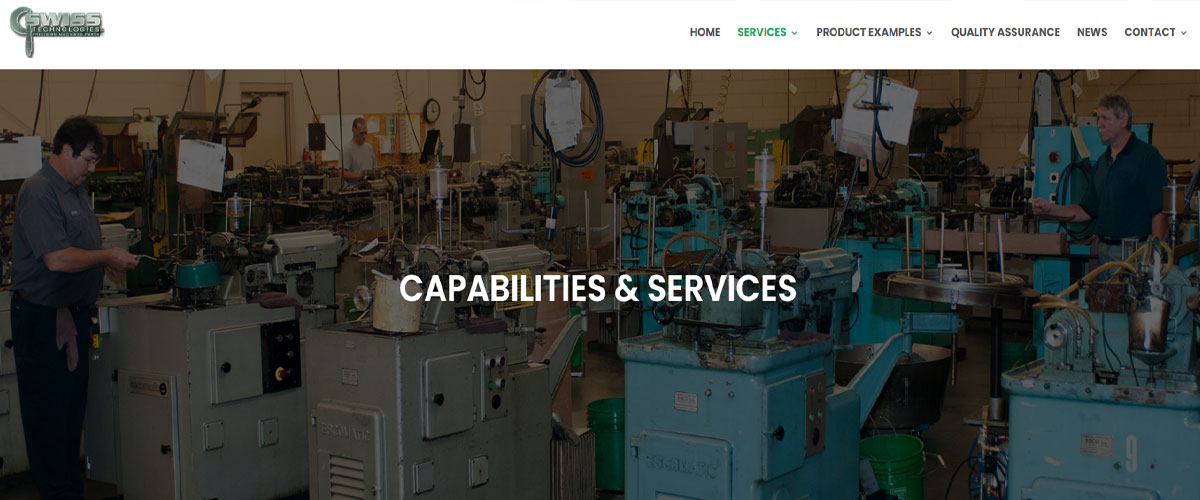

Swiss Technologies Inc.

At Swiss Technologies, we employ a variety of advanced turning equipment to meet customers’ precision machining needs. Primary machining capabilities include turning, threading, drilling, knurling, and broaching parts from 0.020″ to 1.496″ on our Swiss lathes, 2-5/8″ on our multi-spindle screw machines, and up to 3″ on our Mazak and Haas CNC Machines. Our machines include a variety of CNC Swiss machining lathes, Escomatic screw machines, and multi-spindle screw machines.

Having a variety of machinery available for production allows us to efficiently produce a wide range of product types and volumes. For low volume jobs, CNC lathes can machine complex geometries without the cost of dedicated tooling. For higher volume jobs, screw machines can be used for maximum efficiency. This versatility also allows for flexible production scheduling. If a customer contacts us with a quote package that is ideal for the Escomatic machines, but can’t wait for tooling to be fabricated, the initial order can be run on the CNC Swiss lathes. This ensures that the customer receives the parts they need, while providing additional cost savings on future orders.

We work with a variety of materials including steel, stainless steel, brass, aluminum, copper, and some plastics. Tolerances as tight as ±0.0003” depending on part configuration, can be held. All dimensions are confirmed to print using NIST traceable measurement devices. Our ISO 9001:2015 quality management certification is proof of our dedication to providing the highest level of quality and customer service. Because we focus solely on machining and are set up for lights-out manufacturing, overhead is kept to a minimum. By minimizing our operating costs, customers receive premium machining services at a very competitive cost. For more information about our Swiss machining capabilities, see the table below, or contact us directly.

American Micro Industries

American Micro Industries plays a number of roles for a diverse group of clients in the manufacturing, automotive, aerospace, military contracting, and other industries. We can supply bulk quantities of electrical insulation and sound deadening materials. We also have extensive in-house manufacturing capabilities that include CNC machining, die and laser cutting, plastic machining and more.

Koss Aerospace

Koss Aerospace was established in 1975 in Mississauga, Ontario. Originally founded as Koss Machine & Tool Company. The company established it’s reputation by focusing on high quality production of aircraft components. During the early years of business, the company built parts for McDonnell Douglas and Dehavilland Aircraft. Koss was recognized as a Gold Certified Supplier to McDonnell Douglas/Boeing and maintained a ship to stock status.

The company has since changed its name to Koss Aerospace to emphasize their presence in the Global Aerospace and Defense Industry. Today Koss Aerospace proudly continues to supply parts for those same customers; Dehavilland which is now Bombardier and The Boeing Company.

Decatur Mold Tool & Engineering, Inc.

Decatur Mold Tool & Engineering, a business specializing in injection mold manufacturing, is proud to announce national certification as a Women’s Business Enterprise by the Great Lake’s Women’s Business Council, a regional certifying partner of the Women’s Business Enterprise National Council (WBENC).

“For over 55 years, Decatur Mold has built its reputation on delivering quality results for our customers,” said President and CEO, Rhonda Hoerle. “As a family-owned business, we are committed to continuing this legacy of great service for our customers and creating a place where our employees can build fulfilling careers. Our certification as a WBE is the next phase in our development as a company and we are excited to offer our customers the opportunity to add diversity to their supply chains.”

The WBENC standard of certification implemented by the Great Lakes Women’s Business Council is a meticulous process including an in-depth review of the business and site inspection. The certification process is designed to confirm the business is at least 51% owned, operated, and controlled by a woman or women.

By including women-owned businesses among their suppliers, corporations and government agencies demonstrate their commitment to fostering diversity and the continued development of their supplier diversity programs.

MW Industries

Since 1976, MW Industries has been a manufacturer of custom fasteners, brackets, metal stampings and washers for a wide variety of customers in a countless number of industries.

MW Industries is your one-stop machine shop for all your custom metal stampings, precision metal stampings, and drawn metal stampings; custom fasteners in both standard (English) and metric sizes, grades and materials; custom washers, in a wide range of materials and styles; and custom brackets, for your specific application in the metal, plastic or other material you require. Additional value-added services that MW Industries provides include recommending the best material that should be used to produce your component (if needed); prototyping services, proving the design concept is feasible; CAD/CAM capabilities, including ProE, AutoCAD, and other applications, from design assistance (the initial concept) to production, as well as handling your existing CAD files; and a comprehensive in-house quality control system, assuring your component, from a couple of parts to production runs in the millions, consistently meet the tolerances and specifications called for in the design.

Another important part of MW Industries’ success is our knowledgeable staff, with over 400 years’ combined experience in all aspects of custom machining and fabricating. With our extensive line of manufacturing services, from punch press work to complete tool and die services, MW Industries can meet and exceed all of your custom fabrication and machining requirements.

Cheetah Precision

Cheetah Precision is an ITAR registered and ISO Certified manufacturer of precision machined parts. We specialize in complex parts that require state-of-the-art equipment and high-level expertise in machining design and execution. Our long tenured staff of machinists are the backbone of Cheetah Precision. Cheetah’s core competencies are in 5-axis machining, vertical and horizontal CNC Milling, CNC Lathe Turning, and Swiss turning.

Cheetah Precision can manufacture prototype, 1-off parts, specialty, and initial run parts. We are also well versed to meet production run needs from small to large quantities. We can handle your part needs from inception through full scale build production. We welcome longer run, blanket and release-based production opportunities.

For over 40 years Cheetah has taken great pride in its longstanding customer relationships with leaders in the: Military, Aerospace, Defense, Medical, Automotive, Food Processing, Testing Equipment, Specialty Machinery, Packaging, Medical, and Material Handling industries.

Cheetah Precision embraces our continual improvement process. We believe is constantly upgrading, improving, and adding efficiency to our manufacturing operation.

Cheetah Precision operates out of a 40,000 sq ft fully climate-controlled facility in St Paul, MN, and has another 44,000 sq ft operation located in nearby Minneapolis, MN.

Intrex Aerospace

Intrex Aerospace is an experienced precision CNC manufacturing company. We produce tight tolerance machined components for aerospace, defense and space. We understand the importance of producing quality parts, on-time.

Our 75,000 sq. ft. facility has state-of-the-art equipment and a control process system necessary to manufacture precision aerospace components. We are ISO 9001 certified and AS 9100 certified. We are experienced with providing defense components and are ITAR compliant. Our equipment includes 3 and 4 axis vertical and horizontal machine centers and 5-6-7 axis turn/mills, ensuring flexibility in the high-precision machining of complex shapes and sizes. We have multiple CMMs’ located on our shop floor and in our climate-controlled quality lab. We employ a highly experienced staff of aerospace machinists, many with more than 30 years of precision CNC machining experience. We are especially experienced in producing thin wall turn/mill parts. We produce these and other complex aircraft components using a wide variety of aerospace materials. We also have an experienced quality control team that is thoroughly familiar with a wide variety of aerospace quality requirements, protocols and specifications.

In addition to our aerospace machining capabilities, we have a powerful Epicor ERP/MRP system, capable of managing your complex supply chain requirements. Our system is designed to manage demanding long term agreements (LTA). We offer a complete program management solution and can provide everything from engineering support, raw material sourcing, part machining, special process management, documentation and shipment. The efficiencies gained by our management of the supply chain helps reduce lead times and overall costs.

ABS Machining

Established in 1971, ABS Machining has grown to become the recognized global leader in large Machining, Fabrication, and Assembly for OEMs. The key to our success has been exceptional people, unparalleled facilities and an unwavering commitment to quality. Our people are experts in their given field. Their expertise is matched only by their passion for serving our clients. We continue to invest in our people with education programs, cross training and in our internal accredited apprenticeship center. Our facilities are state-of-the-art and equipped to serve our client’s requirements in:

- Large and Heavy Machining

- Production Machining

- Production Fabrication

- Automated and Robotic Welding

- Specialty Welding and Inconel Cladding

- Complex Mechanical Assemblies

- 5 Axis Machining

Our massive fleet of machines and automated welding systems has delivered solutions to the most technically challenging projects. Our commitment to maintaining unparalleled facilities is evidenced by our renowned continuous capital reinvestment initiatives. ABS’s commitment to quality goes well beyond our ISO 9001:2015 Registration. From the inception of all programs, ABS quality professionals work closely with each customer to ensure all their unique requirements are met or exceeded. It is this commitment that has positioned ABS as a strategic supplier to leading OEMs worldwide.

USA CNC Machining companies vs China CNC Machining companies

Comparing CNC machining companies in the USA and China involves considering various factors such as quality, cost, lead times, and communication. Here are some key points to consider:

Quality:

- USA: CNC machining companies in the USA are known for high-quality precision machining. They often adhere to strict quality standards and certifications.

- China: China has a diverse range of CNC machining companies, and while some offer high-quality services, others may vary in terms of quality. It’s crucial to carefully select a reputable Chinese manufacturer.

Cost:

- USA: Manufacturing costs in the USA are generally higher due to factors like labor costs and regulatory compliance. However, the higher cost may be justified by the quality of work and proximity for faster shipping.

- China: China is known for competitive manufacturing costs. Labor is often less expensive, contributing to lower production costs. However, shipping costs and lead times should be considered china cnc machining company.

Lead Times:

- USA: Proximity to the market can result in shorter lead times when working with US-based CNC machining companies. This can be advantageous for projects with tight schedules.

- China: Lead times can vary. While China has efficient manufacturing capabilities, shipping times need to be factored in. Planning ahead is crucial to avoid delays.

Communication and Language:

- USA: Clear communication is often easier when working with companies in the USA due to a shared language and cultural understanding.

- China: Language differences and potential cultural barriers may exist. Choosing a Chinese manufacturer with good communication practices and English proficiency is important.

Technology and Capabilities:

- USA: CNC machining companies in the USA typically have access to advanced technologies and are at the forefront of innovation.

- China: China has a rapidly growing technological landscape, and many CNC machining companies have state-of-the-art equipment. However, the level of technology can vary among manufacturers.

Volume and Scalability:

- USA: US-based companies may be better suited for smaller production runs or specialized, high-precision projects.

- China: China’s manufacturing sector often excels in large-scale production due to lower costs, making it suitable for high-volume orders.

Ultimately, the choice between USA and China for CNC machining depends on the specific requirements of your project, including budget, timeline, and desired quality. It’s essential to thoroughly research and vet potential suppliers in either location before making a decision.

Outsourcing Your CNC Machining Projects to BE-CU Prototype in China

China suppliers have a huge advantage in price compared to American suppliers, but how you choose will determine the results.When selecting a CNC machining manufacturer, crucial considerations include machine quality and reliability, production capacity with lead time, cost-effectiveness, customization and flexibility, and technical support. Here, I strongly recommend suppliers from China: Be-Cu Prototype.

Considering all these factors, BE-CU stands out for our advanced CNC machining services. As an ISO-certified prototype company, BE-CU is well-equipped with advanced CNC machines and parts inspection facilities. They provide comprehensive machining services, covering CNC milling, CNC turning, Electrical Discharge Machining, and various surface finishes. With over 30 years of experience, cutting-edge technology, and a skilled engineering team, BE-CU is a productive and results-driven CNC machining service provider committed to ensuring your satisfaction. You can experience a one-stop solution for machining services, covering CNC milling, CNC turning, EDM, and an array of surface finishes.

Submit your design file for an instant CNC machining quote or email [email protected]. We look forward to collaborating with you!