In such cases, it is convenient to use a machine tool that is capable of simultaneous machining, such as 5 axis machining.Division machining is essential, but what is division machining in the first place? Here, we provide detailed information on the fundamentals of division machining, the main processes and the benefits.

The Basics Of ‘Division And Machining Process.’

What Is Division Machining?

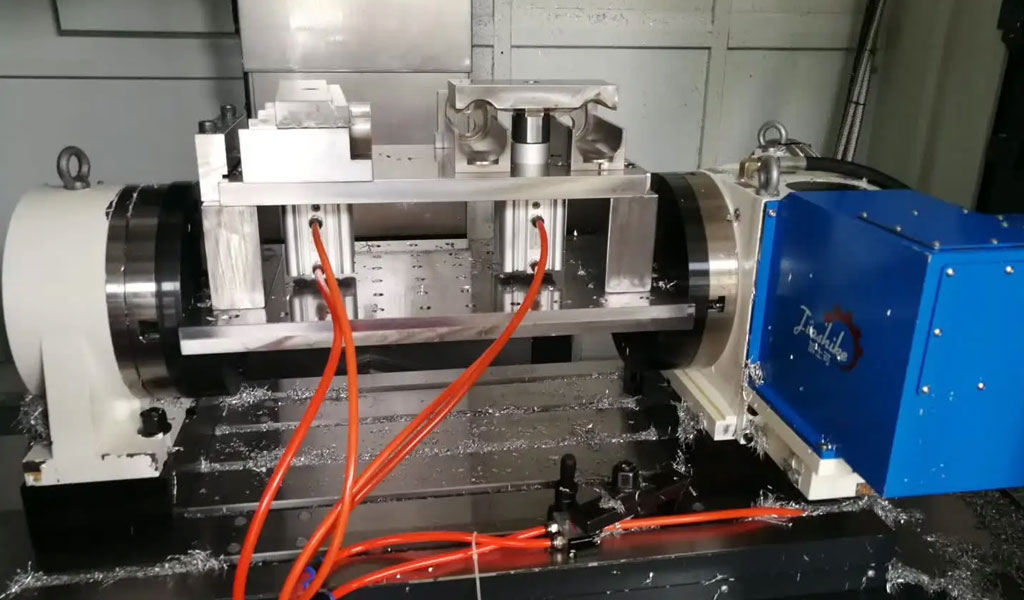

Division machining refers to machining by tilting and fixing the rotary axis at an arbitrary angle, making it possible to realise undercuts and other operations. There are a variety of machining methods, but in recent years, such as ‘division machining 5-axis machining’ has been attracting a lot of attention. The differences between this and normal 5-axis cnc machining are as follows.

5 Axis Machining

Machining is carried out in five axes: the X, Y and Z axes used for 3D machining on general machining centres, plus the rotation and tilt axes.

Indexable 5-Axis Machining

The rotary and tilt axes are rotated and positioned at an arbitrary angle, and machining is carried out in the X, Y and Z axes.

The machining method in which all five axes (XYZ, rotary and tilting axes) are operated simultaneously is known as ‘simultaneous 5-axis machining’, and enables more complex parts to be machined efficiently and accurately for manufacturing.

Main Processes In Division Machining

When division machining, the machine posture of the table is first set so that it is easy for the operator to check. The division machining angle is determined from the shape to be machined, and any angle can be specified by direct input. In some cases, depending on the machine structure and other factors, two different division machining angles can be produced, so check the machine posture so that the operator can easily check the machined part.

Once the machine posture from the operator’s point of view has been created, the tool and workpiece should be tucked in and checked for movement and interference, including the structure, before path calculation. Before actually performing the calculation, check that the division machining angle set in the stroke check matches the machine specifications and start machining.

The Advantages Of Division Machining

The Capable Of Machining From Multiple Directions

In addition, it is possible to set the two machining axes of the rotary shaft and the inclination shaft beforehand, and there is Merritt that can approach the tool from the optimum direction. As a result, the number of steps to replace the work can be reduced, so that it is possible to shorten the machining time and reduce the cost by other machining machines.

In addition, it is possible to reduce the cost by the necessity of the special tool tip, and unnecessary special jig. In addition, it is possible to improve the processing quality by reducing the number of work done by the hand, not only the complicated machining which can not be realized without using the electric discharge machine until now.

The Capable Of Being Processed

As for convenience, it is likely that simultaneous machining is more excellent than the five spindle machining. However, in some cases, it is not always easy to assign five axes machining. When the number of axes to be driven simultaneously increases, the relative position of each axis is relative to the temperature change of the member, the vibration of the head and the member, the backlash, the operation time, and so on.

However, in the world of precision machines, this few microns can be lost. In the five axis machining, fine adjustment is possible for each angle, so it can be processed while finely correcting. This makes it possible to produce more accurate work.

To Reduce The Load On A Machine

In the simultaneous five axis machining, it is not only easy to generate errors of several microns, but by driving simultaneously, the rigidity of the machine becomes low. This can’t be avoided by any chance. Therefore, there are many cases in which five spindle machining is used to avoid the reduction of rigidity. The five axis machining is characterized by the difficulty of reducing the stiffness compared to the five axis machining.

Thus, the simultaneous five axis machining is not superior to the five axis machining in all parts. It is not only the function but also the precision of the construction of the object that the company aims at, and the synthesis of the machine, etc., and there is an option of choosing the five axis machining machine which is not the five axle machine at the same time.

Division machining, also known as division 5-axis machining, enables more detailed machining by adjusting the rotational and tilting axes in addition to the three XYZ axes in advance. Demand is considerably higher than for simultaneous 5-axis machining, due to the higher precision and rigidity of the machine itself. When performing indexed 5 axis machining, be sure to select a CAM that supports indexed machining.