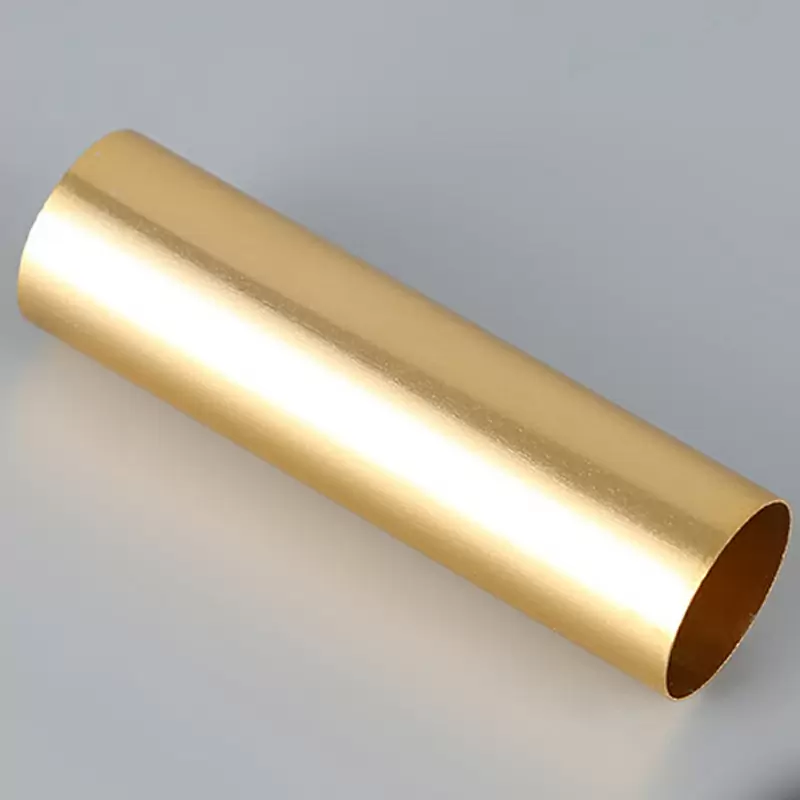

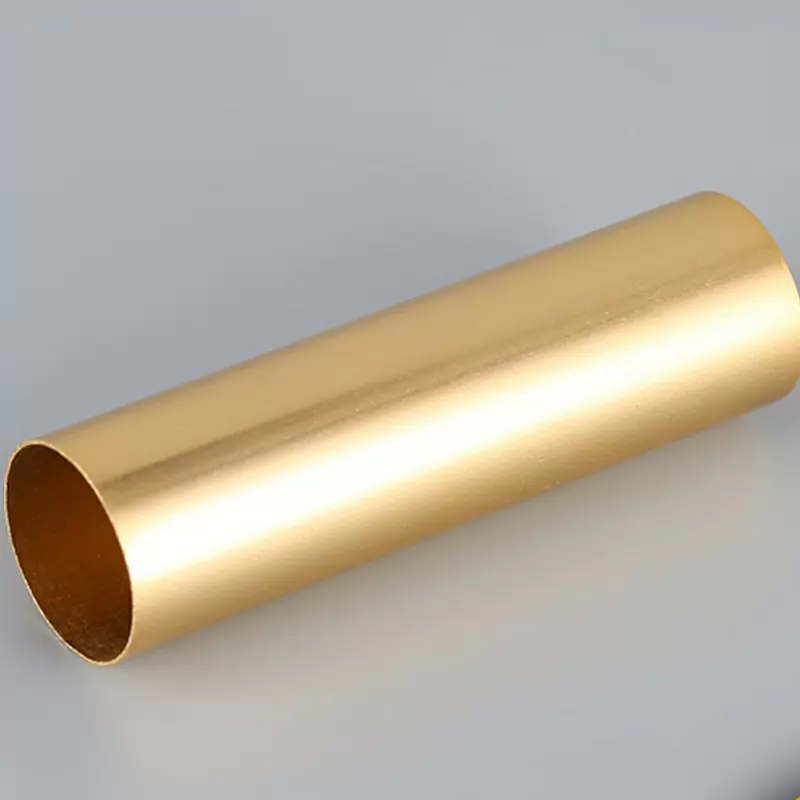

Hollow Aluminum Tube For Insulation Cup Shell

- Material: Aluminum 6061

- Custom Process: WEDM

- Other Process: Turning,Milling,

- Surface Roughness: Ra6.3-800

- Annual Volume: 1,000 per year

- Size: Custom

- Application: Cup Shell

- Precision: ± 0.0001”

High-Quality Wire-cut Machining Of Hollow Aluminum Tube For Insulation Cup Shell

Custom manufacturer of insulating cup shell straightening and cutting line hollow aluminum tubes. The materials used include bright basic carbon steel, brass, aluminum and stainless steel. It can handle wires up to 0.5 inches in diameter and cut lengths up to 12 feet while maintaining tolerances of +/-0.002 inches to +/-0.0005 inches. Available with electroplated and galvanized finishes. Use a digital microscope and a micrometer to check the wire and test its tensile strength and bending. Provide chemical certification documents. Other value-added services include welding, maintenance and processing, inventory management and packaging. Industry highlights include concrete pipes, woodworking, consumer products, seating, automobiles, and retail.

Why Choose Our Wire-cut Machining Of Hollow Aluminum Tube For Insulation Cup Shell Service?

- 2m Large Wire Cutting

- Large-Scale Automobile Die Cutting

- Large-Scale Furniture Die Cutting

- 40 Sets Of Large-Stroke Precision Wire Cutting

- Single Side Cutting 40°, Cutting Height 1 Meter

- Load-Bearing More Than 5 Tons, Swing Large Taper Wire Cutting

- Quantity flexibility. From prototypes to low/high volume production, we can meet your requirements with exact specifications.

- Quality Assurance. Our team of highly skilled workers and strict quality control and inspection will ensure the quality of the final parts.

- Strong Professionalism. Electric Discharge Machining services at BE-CU will maintain integrity, consistency, productivity, and economy.

- High Standard. Our purpose is to achieve perfection in wire cut EDM machining through continuous improvement and upgrading.

- Customer satisfaction. Fast turnaround, on-time delivery, high quality, competitive prices, and best service help us win high customer satisfaction.

Contact Be Cu Now for your Custom Wire Cutting Service, We are your best online wedm services choice!

Wire Cutting Specifications of Wire-cut Machining Of Hollow Aluminum Tube For Insulation Cup Shell

| Item Name | WEDM(Wire Cutting) |

| Material | Metal |

| Thickness | 0.5mm-20mm,Depends on your products |

| High Precision | +/-0.0001mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Zinc plating,Electroplating,etc |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU Wire Cutting Company

BE-CU is a specialist that can fabricate industrial parts and custom machined parts using a wide variety of manufacturing techniques. With Wire Cutting Services at be-cu.com, you can get your wire EDM parts in a much more accurate and fast way, compared to conventional machining. Our newest wire cutting machines can meet your needs of high volume while maintaining high repeatability, top quality and tight tolerance. Over the past years, we have earned a good reputation for producing custom parts with reasonable pricing and on-time delivery, and also capable of working with electrical discharge machining equipment to provide wire cut EDM parts and services for our customers. Our EDM services offer experience and excellence in all types of EDM machining, welcome to submit an inquiry online.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles