In daily use of CNC lathes, we often encounter some malfunctions. Having a basic understanding of CNC lathe failures, simply identifying the cause of the failure, and mastering simple maintenance methods can quickly restore the lathe to normal without causing serious losses to production. Today I will take stock of some common faults of CNC lathes and recommend them to your collection.

Common faults of CNC lathes are divided into two categories, namely deterministic faults and random faults. A deterministic fault refers to a fault that occurs when the machine tool hardware is damaged. This fault is irreversible and must be repaired before it can disappear. Random failures refer to accidental failures. The cause of the failure is often related to the installation quality of components, parameter settings, software design, and working environment. It can generally be recovered by restarting the machine, but the cause of the failure is difficult to find.

The way to avoid deterministic faults is regular maintenance, while the way to avoid random faults is to ensure reliable installation and connections, and strengthen maintenance and inspection of the CNC system.

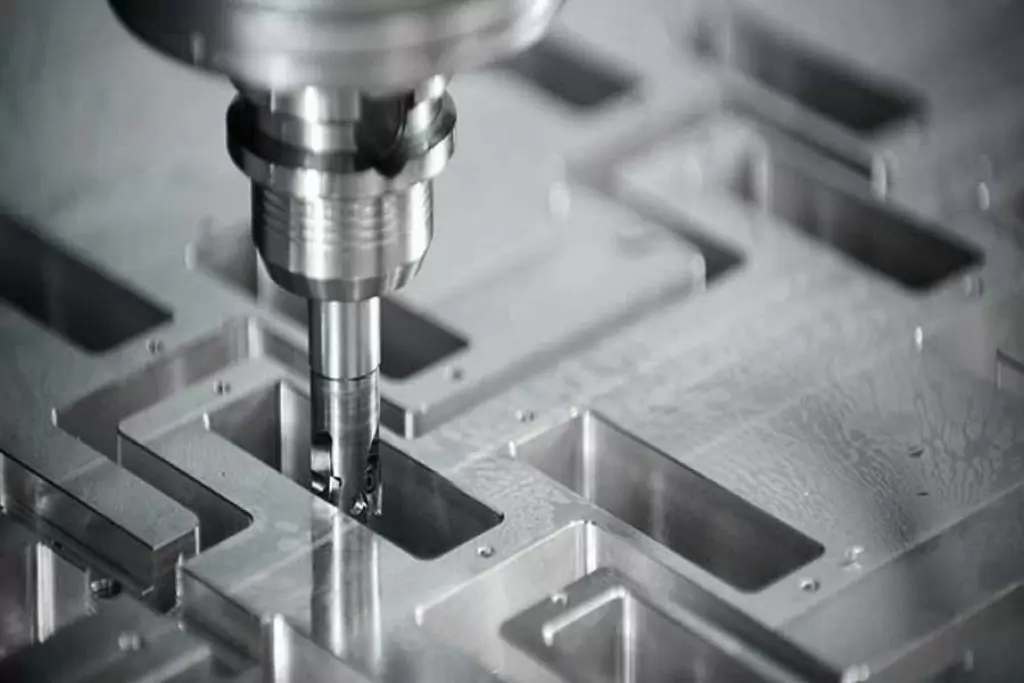

Spindle component failure

Among the spindle components, the automatic tool clamping and automatic speed adjustment devices are prone to failure. When the tool cannot be released after being clamped, there may be a problem with the tool releasing hydraulic cylinder and the travel switch device, and the nut on the butterfly spring needs to be adjusted.

Feed rotation chain failure

When the motion quality of the machine tool decreases, and problems such as operation interruption, reduced positioning accuracy, increased bearing noise, and crawling occur, it may be that the feed rotation chain is faulty. Such faults can be solved by improving transmission accuracy, rotational stiffness, and motion accuracy.

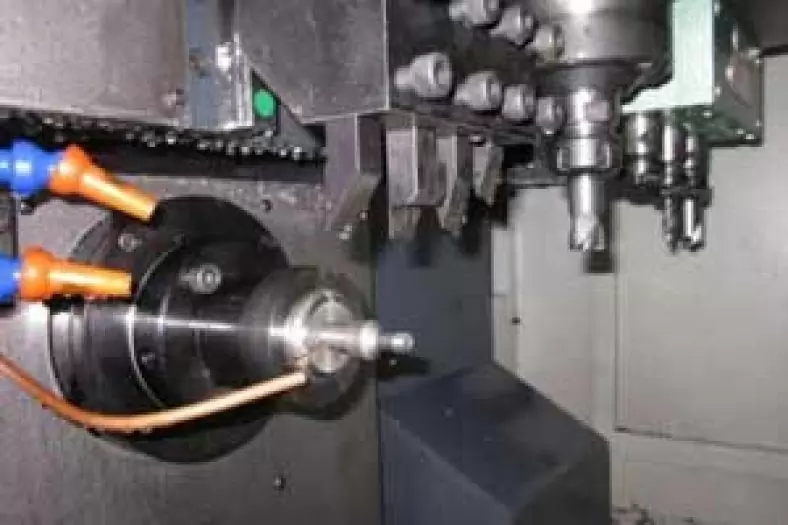

Automatic tool change failure

When the tool handle held by the robot is unstable, the movement error of the robot hand is large, the tool change action is stuck, etc., then there is a problem with the automatic tool change device. For such problems, different maintenance faults should be given according to different situations. If the tool clamp is not tight, the clamping spring needs to be adjusted, or the manipulator clamping pin needs to be replaced.

Supporting device failure

Failure of machine tool supporting devices is also one of the common faults. When the hydraulic system fails, a variable pump should be used to reduce the heat of the hydraulic system; when the pneumatic system fails, the lubrication condition should be checked and the sealing of the pneumatic system should be checked; when the cooling system fails, the coolant nozzle should be cleaned.

The movement position of each axis causes switch pressing failure.

The long-term operation of the machine tool may cause the movement of each axis of the machine tool to cause a switch pressing failure. Therefore, it is necessary to regularly check and replace the travel switch to reduce the negative impact of such failures on the machine tool.

There is no picture on the display screen after the CNC machining china system is turned on.Check the display cable for a bad connection, and reconnect it if so.Check whether the display voltage is normal.Check the DC power circuit. There is no alarm, the machine does not move, there may be a problem with the circuit board or the ROM board controlled. There is no display, but the machine tool can still operate, indicating that the control part of the numerical control system is normal, only the display circuit connection or printed circuit board has a problem.

The CNC machine cannot operate. First, it is possible that the reset button of the machine tool is always on, and the CNC system is in an emergency stop state. Second, the movement of the coordinate rod on the screen indicates that the machine tool is in a locked state. The third is that the specified feed rate is incorrect, and the system handles the alarm state. The machine cannot return to the reference point. The reason is that the encoder wiring is faulty, or the limit switch or proximity switch is faulty. The value displayed on the panel does not match the actual feed value of the machine tool. The position detection element should be checked.

The system freezes or fails to start normally after booting. Reboot, if it still cannot be eliminated, reload the machine parameters. The tool holder does not move or move around.The wiring of the sending board or the power line is short-circuited, or the Hall element is burned out, just replace the element The tool holder is loose, the clamping is not tight, and the work is unstable. Check the mechanical parts of the knife holder and remove the dirt from the mating part.

Override processing. Machine tool overtravel (first soft limit, second stroke limit). Manually move the machine tool overtravel coordinate axis to within the safe travel, and then press the reset key to cancel the alarm. Alarm handling. Check the alarm information table in the machine tool maintenance manual, find out the cause of the failure, and take corresponding measures to eliminate it.

There are many reasons for the failure of CNC machine tools, and only some common simple failures are listed here. CNC maintenance is a highly specialized subject. What is needed is a complex talent. For the operation, the focus should be on the application of CNC machine tools. If a fault occurs, it is generally repaired by professional maintenance personnel. Without this knowledge, it cannot be forced. However, for general operation failures, it is required to be able to master the troubleshooting methods and to be able to handle the troubleshooting.

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]