Bringing a product to market cost-effectively is crucial for startups and businesses of all sizes. Here are some steps you can follow to achieve this goal:

Conduct Market Research

Start by thoroughly researching your target market. Identify the needs, preferences, and purchasing behavior of your potential customers. This will help you develop a product that meets their demands and ensures a higher chance of success.

Develop A Lean Business Plan

Create a detailed business plan that outlines your product concept, target market, marketing strategy, and financial projections. Keep the plan concise and focused, emphasizing cost-effective methods for each aspect of your business.

Prototype And Test

Build a prototype of your product to test its functionality, usability, and market appeal. You can use cost-effective methods like 3D printing or low-cost materials to create initial rapid prototyping parts. Gather feedback from potential customers and make necessary improvements before moving forward.

1.How Does Prototype And Test Before Your Ideal Enter The Market

Prototyping and testing your product before launching it into the market is a critical step to ensure its success. Here’s a step-by-step approach to prototype and test effectively:

- Determine your testing goals: Clearly define the objectives you want to achieve through prototyping and testing. Identify the specific aspects of your product that you want to evaluate, such as functionality, usability, durability, or market appeal.

- Create a basic prototype: Develop a basic version of your product that represents its core features and functionalities. This initial prototype doesn’t have to be perfect but should be sufficient for testing and gathering feedback. You can use low-cost materials, off-the-shelf components, or even 3D printing to create your prototype.

- Test internal functionality: Conduct internal tests to assess the functionality and performance of your prototype. Identify any technical issues, flaws, or areas for improvement. This can involve running simulated tests, performing experiments, or using quality control techniques.

- Gather feedback from a focus group: Assemble a small group of target customers or individuals who represent your intended user base. Present your prototype to them and encourage open and honest feedback. Ask specific questions about usability, features, and overall impressions. Take notes and document their suggestions and concerns.

- Refine your prototype: Use the feedback gathered from the focus group to refine and improve your prototype. Address any identified issues, make necessary design modifications, and incorporate suggested enhancements. Iterate on your prototype until you feel it adequately addresses the feedback received.

- Conduct user testing: Expand your testing to a larger group of potential users. Allow them to interact with your prototype and observe their behavior, preferences, and difficulties. User testing can provide valuable insights into how customers will use your product and help identify any usability issues or design flaws.

- Iterate and repeat: Based on the user testing results, refine your prototype further. Continue the cycle of testing, gathering feedback, and making improvements until you achieve a satisfactory level of functionality, usability, and customer satisfaction.

- Test in real-world conditions: If feasible, test your prototype in real-world scenarios or conditions that closely mimic how your product will be used. This can include field testing, beta testing with a limited group of customers, or pilot studies. Observe how your prototype performs in these conditions and gather feedback accordingly.

- Validate market demand: Alongside prototype testing, continuously validate the market demand for your product. Engage with potential customers, conduct surveys, or even set up pre-orders to gauge interest and demand. This will help you confirm that your product aligns with market needs before investing in large-scale production and marketing.

- Finalize the product design: Once you are confident in the performance, usability, and market appeal of your prototype, finalize the product design. Incorporate any necessary modifications or improvements based on the feedback received during testing.

By following these steps, you can refine your product, ensure it meets customer expectations, and minimize the risk of launching an ineffective or flawed product in the market. Prototyping and testing enable you to make informed decisions, validate your ideas, and increase the chances of a successful product launch.

2.The Prototype And Test Methods Of Products

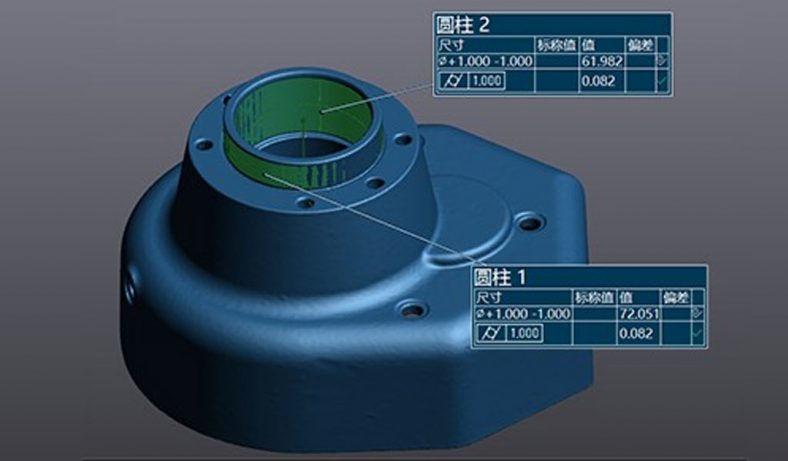

When it comes to prototyping and testing individual parts of a product, several methods can be employed. These methods allow you to assess the functionality, fit, and performance of individual components before integrating them into the final product. Here are some commonly used methods for parts prototyping and testing:

- 3D Printing: 3D printing, also known as additive manufacturing, enables you to create physical prototypes of parts using computer-aided design (CAD) files. It allows for quick and cost-effective production of parts with complex geometries. 3D printing is suitable for plastic, metal, or even composite materials.

- CNC Machining: Computer Numerical Control (CNC) machining involves using computer-controlled machinery to precisely cut, shape, and drill parts from a solid block of material. CNC machining is ideal for producing functional prototypes or low-volume production parts from materials like metal, plastic, or wood.

- Laser Cutting: Laser cutting is a subtractive manufacturing process that uses a high-powered laser to precisely cut or etch parts from flat sheets of material, such as plastic, wood, or metal. It is particularly suitable for creating 2D parts and prototypes with intricate designs.

- Sheet Metal Fabrication: Sheet metal fabrication involves cutting, bending, and assembling thin sheets of metal to create parts or enclosures. It is commonly used for prototypes and low-volume production of metal parts. Sheet metal prototypes can be fabricated using various techniques like laser cutting, bending, and welding.

- Rapid Tooling: Rapid tooling is a method that bridges the gap between prototyping and full-scale production. It involves creating molds or tooling quickly and cost-effectively to produce prototype parts using processes like injection molding or casting. Rapid tooling enables you to evaluate the functionality and performance of parts under production-like conditions.

- Functional Testing: Once you have fabricated the individual parts, you can perform functional testing to ensure they meet the required specifications and perform as intended. Functional testing may involve mechanical stress testing, load testing, electrical testing, or other specific tests relevant to the part’s function.

- Fit and Assembly Testing: Parts prototyping should also include fit and assembly testing to ensure that the components align properly and fit together seamlessly. This testing helps identify any issues related to mating surfaces, tolerances, or interference between parts.

- Iterative Design and Testing: As with product prototyping, parts prototyping often involves an iterative process. You create and test multiple iterations of the parts, incorporating design modifications and improvements based on the feedback and results obtained during testing. This iterative approach helps optimize the parts’ performance and ensures they meet the required standards

The choice of parts prototyping and testing methods will depend on factors like the complexity of the parts, material requirements, production volume, and available resources. It’s essential to select the most appropriate method for each part to ensure accurate evaluation and successful integration into the final product.

Seek Early Feedback And Validation

Engage with your target audience early on to validate your product concept and gather feedback. You can conduct surveys, interviews, or run focus groups to gain insights into their needs and expectations. This will help you refine your product and avoid costly mistakes.

Build Strategic Partnerships

Collaborate with suppliers, manufacturers, and distributors who offer cost-effective solutions. Look for partners who are willing to work with startups and offer competitive pricing. Negotiate favorable terms and explore options like drop-shipping or consignment agreements to reduce upfront costs.

Optimize The Supply Chain

Efficient supply chain management can significantly impact your product’s cost. Evaluate your supply chain from raw material sourcing to manufacturing and distribution. Look for opportunities to reduce costs, eliminate waste, and streamline processes. Consider outsourcing non-core functions to specialized providers if it proves cost-effective.

Bootstrap And Minimize Overheads

Keep your expenses in check by bootstrapping wherever possible. Avoid unnecessary spending on lavish offices or expensive equipment. Leverage technology to reduce overheads, such as utilizing cloud-based software instead of investing in physical infrastructure.

Implement A Cost-Effective Marketing Strategy

Focus on targeted and cost-effective marketing tactics. Leverage digital marketing channels like social media, content marketing, and search engine optimization (SEO) to reach your target audience without breaking the bank. Encourage word-of-mouth marketing and leverage customer referrals.

Start With A Limited Product Launch

Rather than aiming for a large-scale launch, consider starting with a limited release to a specific geographic area or a niche market segment. This approach allows you to test your product in a controlled environment, gather feedback, and make improvements before scaling up.

Continuously Iterate And Improve

Monitor customer feedback, market trends, and competition regularly. Iterate on your product based on the insights you gather to make it more cost-effective and aligned with market demands. Continuous improvement will help you stay competitive and reduce costs in the long run.

Bringing a product to market cost-effectively requires careful planning, research, and resource optimization. Stay agile, adaptable, and open to making adjustments along the way to maximize your chances of success.

Bring Products to Market Cost-Effectively

There’s a lot more to consider before deciding upon a manufacturing process, and the choices that you make can mean the difference between bringing a product to market cost-effectively or saddling your project with avoidable expenses. Be-Cu prototype company can help you from prototype through small batch machining and has worked with companies like yours during new product development (NPD) and new product introduction (NPI).