Time flies, and it has been ten years since I operated CNC lathes in a blink of an eye. Ten years of hard work have allowed me to accumulate some cnc machining skills and experience of CNC lathes, and communicate with colleagues.

Due to frequent replacement of machined parts and limited factory conditions, for ten years we have been programming by ourselves, setting tools by ourselves, debugging and completing the processing of parts by ourselves. To sum up, the operating skills are divided into the following points:

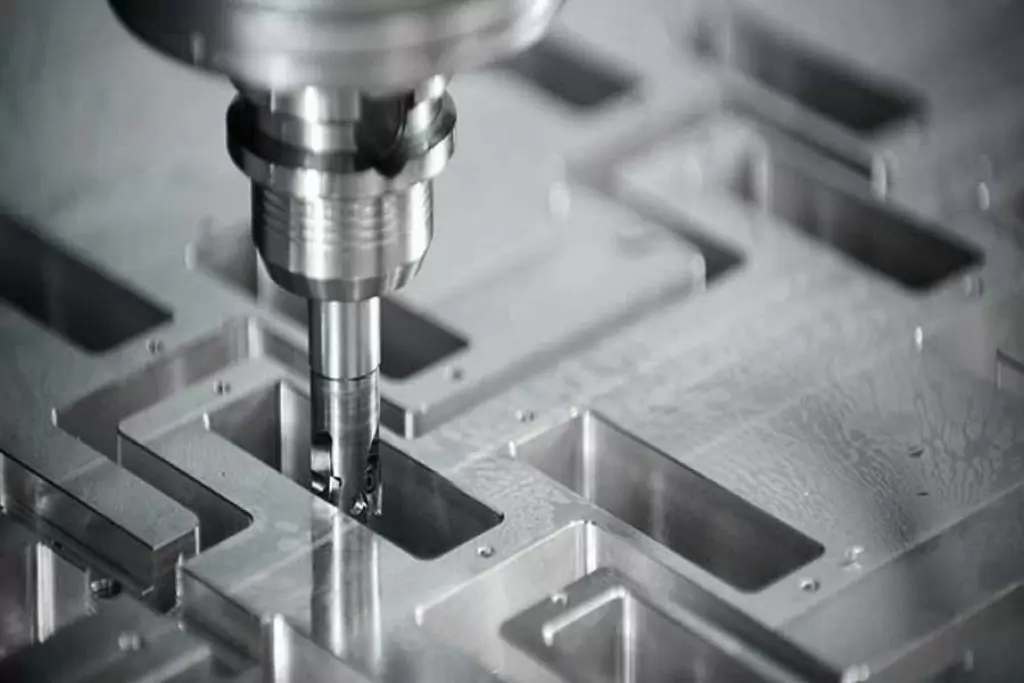

Programming Skills

Because our factory has high requirements on the precision of processed products, the items to be considered when programming are:

(1) The processing sequence of the parts

Drill first and then flat end (this is to prevent the shrinkage of material during drilling); first rough turning, then fine turning (this is to ensure the accuracy of the parts); first machining with large tolerances and last machining with small tolerances (This is to ensure that the surface of the small tolerance dimension is not scratched and prevent the deformation of the part).

(2) Choose a reasonable speed, feed and depth

Choose a reasonable speed, feed and depth of cut according to the hardness of the material. My personal summary is as follows:

- High speed, high feed rate and large depth of cut are selected for carbon steel materials. For example: 1Gr11, select S1600, F0.2, 2mm depth of cut;

- Cemented carbide chooses low speed, low feed and small depth of cut. Such as: GH4033, select S800, F0.08, depth of cut 0.5mm;

Select low speed, high feed rate and small depth of cut for titanium alloys. Such as: Ti6, choose S400, F0.2, depth of cut 0.3mm. Take me processing a part as an example: the material is K414, which is a very hard material. After many tests, the final selection is S360, F0.1, and the depth of cut is 0.2, and only qualified parts can be processed. There are many more programming skills, and my personal summary is probably this.

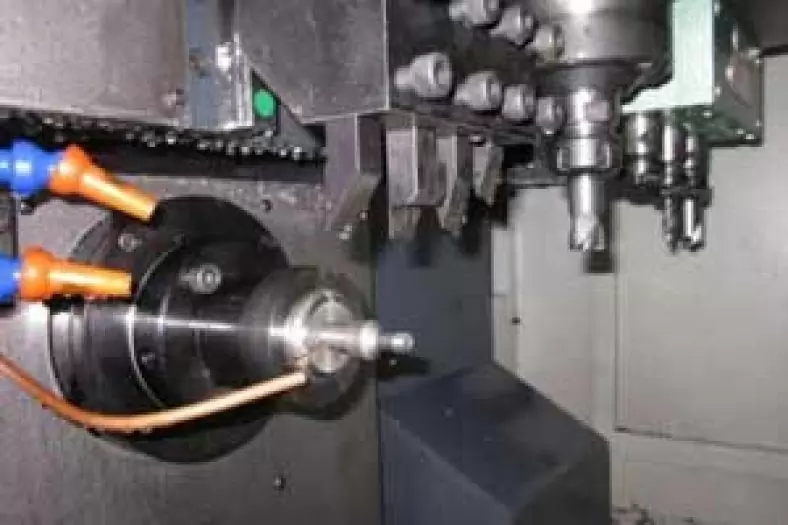

The Knife Skills

Tool setting is divided into tool setting instrument tool setting and direct tool setting. Most of the lathes in our factory do not have a tool setting instrument, which is a direct tool setting. The tool setting skills mentioned below are direct tool setting. First select the center of the right end face of the part as the tool setting point, and set it as the zero point.

After the machine tool returns to the origin, each tool that needs to be used is set at the zero point of the center of the right end face of the part; when the tool touches the right end face, enter Z0 and click to measure, The measured value will be automatically recorded in the tool offset value of the tool, which means that the Z-axis tool setting is good, and the X tool setting is a trial cutting tool setting.

If x is 20mm) input x20, click to measure, the tool compensation value will automatically record the measured value, then the x-axis is also correct; this tool setting method, even if the machine tool is powered off, it will not change after the power is restarted. The tool value is suitable for mass production of the same part for a long time, during which the lathe does not need to be re-calibrated.

Debugging Skills

After the parts are programmed, they need to be tested and debugged after the tool is set. In order to prevent errors in the program and mistakes in tool setting, resulting in collision accidents, we should first perform idle travel simulation processing and face them in the coordinate system of the machine tool. The tool is moved to the right by 2-3 times the total length of the part; then start the simulation processing, after the simulation processing is completed, confirm that the program and tool setting are correct, and then start processing the part. , and then find a full-time inspection and inspection. After the full-time inspection is confirmed, it means that the debugging is over.

Complete The Processing Of Parts

After the first piece of trial cutting is completed, the parts will be mass-produced, but the qualification of the first piece does not mean that the whole batch of parts will be qualified, because during the processing, the tool will be worn due to the difference of the processing material, and the processing material Soft, the tool wear is small, the processing material is hard, the tool wear is fast, so in the process of processing, it is necessary to check frequently, increase and decrease the tool compensation value in time, and ensure the qualified parts.

Take a part as an example, the processing material is K414 , The total processing length is 180mm. Because the material is very hard, the tool wears very quickly during processing. From the starting point to the end point, the tool wear will produce a slight degree of 10-20mm. Therefore, we must artificially add 10-20mm in the program. In this way, the qualified parts can be guaranteed.

In a word, the basic principles of machining: first rough machining, remove the excess material of the workpiece, and then finish machining; avoid vibration during machining; avoid thermal denaturation of workpiece during machining.

There are many reasons for vibration, which may be overloaded. Large; it may be the resonance between the machine tool and the workpiece, or the rigidity of the machine tool may be insufficient, or it may be caused by the passivation of the tool. We can reduce the vibration by the following methods; reduce the lateral feed and machining depth, check Whether the workpiece clamping is reliable, increase the speed of the tool and reduce the speed to reduce the resonance. In addition, check whether it is necessary to replace a new tool. The above is a summary of my skills in CNC lathe machining over the years.In addition, in order to operate the CNC machine tool safely and prevent the machine tool from colliding, I have the following experience:

It is often heard from others that you can’t learn machine tool operation without touching the machine tool. This is a very wrong and harmful understanding. The machine tool collision will greatly damage the accuracy of the machine tool, and it will have different effects on different types of machine tools. Generally speaking , It has a greater impact on the machine tool with low rigidity, such as the T6 horizontal lathe we are using now, once the machine tool collides, the impact on the accuracy of the machine tool is fatal.

Therefore, for high-precision CNC lathes, collisions must be avoided. As long as the operator is careful and masters certain anti-collision methods, collisions can be completely prevented and avoided. The following are some experiences of anti-collision of CNC lathes: the main reasons for the collision: one is the input error of the diameter and length of the tool; the other is the input error of the size of the workpiece and other related geometric dimensions and the initial position of the workpiece Positioning error; the third is that the workpiece coordinate system of the machine tool is set incorrectly, or the machine zero point is reset during the processing process, and changes occur. Most of the machine tool collisions occur during the rapid movement of the machine tool, and the hazards of collisions at this time are also the greatest. Absolutely avoid.

Therefore, the operator should pay special attention to the initial stage of the machine tool executing the program and when the machine tool is replacing the tool. At this time, once the program is edited incorrectly and the diameter and length of the tool are entered incorrectly, collisions are likely to occur.

At the end of the program, the tool retraction sequence of the CNC axis is wrong, then a collision may also occur. In order to avoid the above-mentioned collision, the operator should give full play to the functions of the five senses when operating the machine tool, and observe whether the machine tool has abnormal movement, whether there is sparks, whether there is noise and abnormal noise, whether there is vibration, and whether there is a burning smell. If an abnormal situation is found, the program should be stopped immediately.

After the machine tool problem is solved, the machine tool can continue to work. In short, mastering the operation skills of CNC machine tools is a gradual process and cannot be accomplished overnight. It is based on mastering the basic operation of machine tools, basic machining knowledge and basic programming knowledge. The operation skills of CNC machine tools are not static, it is an organic combination that requires operators to give full play to their imagination and hands-on ability, and it is an innovative labor. At the same time, I hope that my skills and experience can bring some help to my colleagues.

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]