Advancedness means that the equipment must have the technical content of the development level of the times; reliability means the mean time between failures and the mean failure rate of the equipment, especially whether the control system has passed the quality inspection and assessment of the national authority; the maintainability of china cnc machining tools It refers to whether it is easy to maintain, whether there is a good market for spare parts, whether the technical data for various maintenance are complete, whether there is good after-sales service, whether the maintenance technical ability is available, and whether the equipment performance-price ratio is reasonable.

Preparation Before Maintenance Of CNC Machine Tools

Get site information, site conditions and fault information as quickly as possible. Such as the feed and spindle drive model of CNC Shenyang machine tool, alarm indication or failure phenomenon, whether there are spare parts on site, etc.

Based on this, pre-analyze the causes and locations of possible failures, and then prepare relevant technical data, maintenance service tools and instrument spare parts before setting off to the site, so as to be aware of it.

Preventive Maintenance Of CNC Machine Tools

As the name implies, the so-called preventive maintenance is to pay attention to eliminate the factors that may cause equipment failure and difficult to solve after the failure occurs before the failure occurs. The purpose of preventive maintenance is to reduce the failure rate, and its work mainly includes the following aspects.

Selection of CNC equipment from the perspective of maintenanceIn the equipment selection research, in addition to the availability parameters of the equipment, its maintainability parameters should include: the advanced nature, reliability and maintainability technical indicators of CNC Shenyang machine tool equipment.

Special attention should be paid to the integrity of drawings and data, backup system disk, CNC Shenyang machine tool PLC program software, system transmission software, transmission means and operation passwords, etc., all of which are indispensable. The technical training of the user unit cannot go through the motions.

These must be indicated in the order contract and implemented carefully, otherwise it will bring trouble to the future work.In addition, if it is not a special situation, try to use the same series of CNC machine tool systems from the same company, so that it is good for spare parts, drawings, data, programming and operation, and is also conducive to equipment management and maintenance.

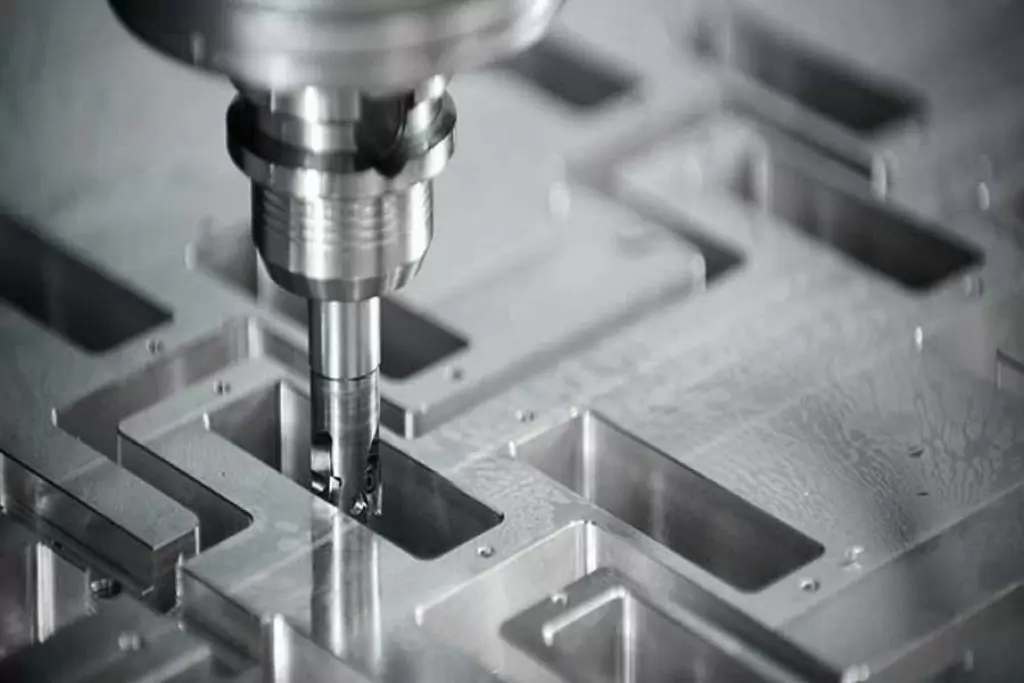

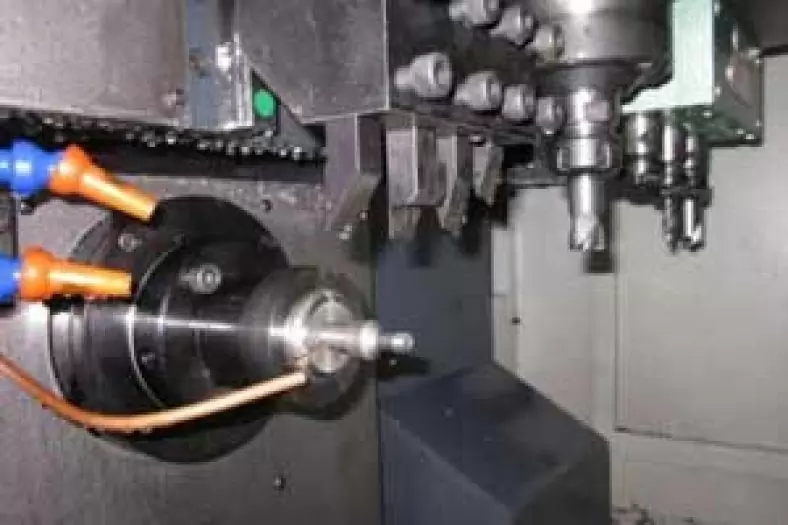

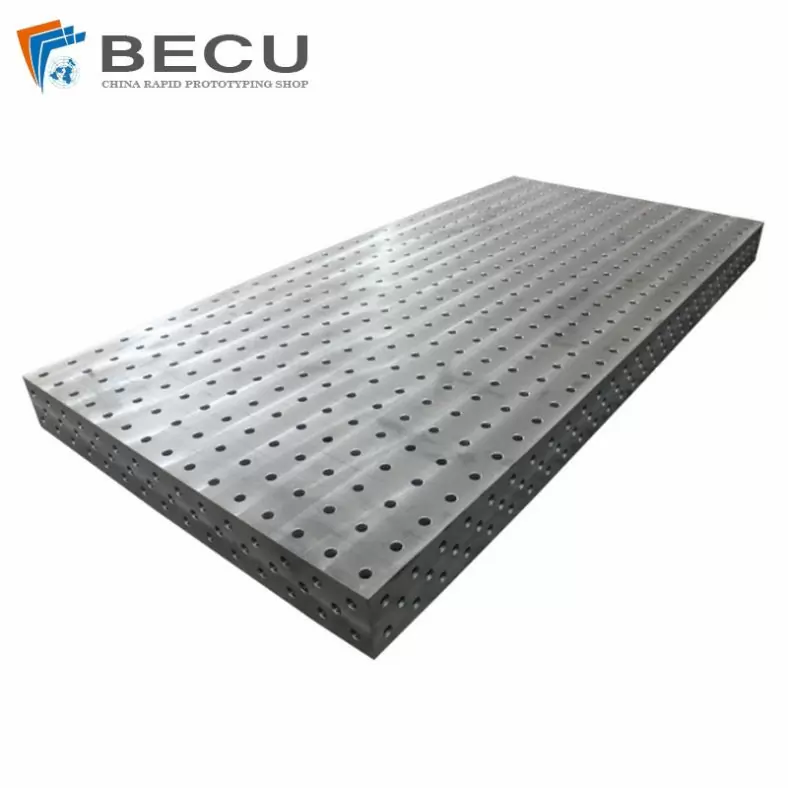

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]