In recent years, the global manufacturing industry has undergone significant transformations, with computer numerical control (CNC) technology playing a pivotal role. However, amidst this evolution, an intriguing phenomenon has emerged – China CNC suppliers’ refusal to engage in gun machining. This article delves into the multifaceted reasons behind this decision, analyzing legal, ethical, economic, and geopolitical factors that shape the landscape of gun machining in China. By exploring this issue, we gain insights into the complex interplay between technology, regulation, and morality.

What Is Gun Machining

As one of the most influential inventions in human history, Gun have always been an important tool in warfare and civilian defense. This article will introduce in detail the technical development, key technologies, and future trends of firearms design and manufacturing.

Firearms can be traced back to the 13th century in China. At that time, both gunpowder and firearms were in their infancy, mainly in the form of artillery and muskets.

The basic principle was to use the gas expansion generated by gunpowder to push the projectile out of the barrel and hit the target.

With the advancement of science and technology, gun manufacturing has gradually moved towards specialization and standardization. Since the 16th century, European countries have carried out a series of technological innovations in the field of firearms manufacturing, such as matchlock guns and fire sickle guns, which have greatly improved the range, power and accuracy of firearms.

At the same time, the firearms manufacturing process has also been developed, and technologies such as metal processing and casting have been gradually applied to the production of firearms, improving the quality and performance of firearms.

In the 19th and 20th centuries, with the advancement of the Industrial Revolution, gun manufacturing ushered in a golden age of development. During this period, countless epoch-making firearms came out, such as Bolt action rifles, revolvers, automatic rifles and so on. The emergence of these firearms not only enriched the types of firearms, but also greatly improved the efficiency and lethality of warfare.

The Importance Of Gun Design

Firearm design is the core factor affecting firearm performance, service life and user experience. An excellent firearm design needs to comprehensively consider the following aspects:

- Shooting accuracy: Shooting accuracy is an important indicator to measure the performance of firearms. Good firearm design reduces the spread circle and improves ballistic stability, making it easier for the shooter to hit their targets.

- Reliability: The reliability of firearms is directly related to the safety of users. Excellent firearm design should ensure that the firearm can work normally in various harsh environments and reduce the failure rate.

- Safety: Safety is the first principle of firearm design. When designing, it is necessary to consider various possible misoperations and install safety devices to avoid accidental injuries.

- Comfort: Comfort is an important factor affecting user experience. A good firearm design needs to consider the comfort of the shooter during use, including grip, trigger, recoil, etc., to improve the stability and accuracy of shooting.

- Ease of use: Ease of use is an important indicator to measure the quality of firearm design. Excellent firearm design should be easy for users to operate, maintain and clean, so as to reduce the difficulty of use and maintenance costs.

- Adaptability: The design of firearms should take into account the needs of different users and have certain adaptability. Through adjustable design, modular structure, etc., the firearm can be adapted to different usage scenarios and user needs.

- Innovation: On the premise of ensuring the basic requirements such as performance and safety, firearms design should constantly pursue innovation and introduce new technologies, new materials and new concepts to meet market needs and improve competitiveness.

Influencing Factors Of Gun Manufacturing Process

With the advancement of technology, modern firearms manufacturing technology has been developed to a new level. High-precision CNC machining, the development of material science, and advanced production technology all provide strong support for modern gun manufacturing.

The quality of a firearms manufacturing process is influenced by many factors, including design, materials, machining accuracy and quality control. In order to ensure the performance and safety of firearms, manufacturers need to strictly control these influencing factors.

The development of new materials had a profound impact on gunsmithing. The use of new materials such as high-performance plastics, ceramics, and lightweight alloys has greatly reduced the weight of firearms and improved their durability and performance.

Firearm Structure Design

Firearm structural design includes fire control system design, aiming device design, casing and barrel design, etc. These designs directly affect the performance and user experience of the firearm.

- Fire control system design: The fire control system is the core component of the firearm, responsible for triggering the firing of bullets. The design of the fire control system needs to take into account safety and reliability to ensure that the firearm can work normally in various environments.

- Sighting device design: Sighting device is an important part of firearms, it helps the shooter to accurately aim at the target. Aiming devices are designed with ease of use, accuracy and adjustability in mind to suit the needs of different shooters.

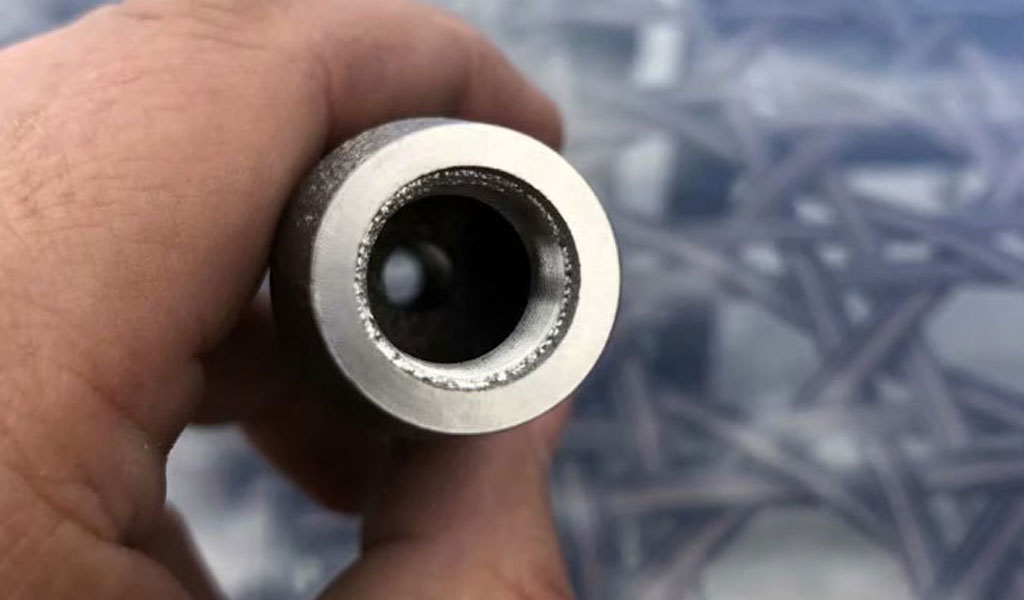

- Receiver and barrel design: The receiver and barrel are the main structural components of the firearm, and their design directly affects the weight, size and stability of the firearm. A reasonable design can improve shooting accuracy and reduce the burden on the shooter.

The Firearms Machining Process

The production process of firearms includes metal processing, surface treatment technology, assembly and quality control.

- Metal Manfacturing: Metal CNC Machining is an important link in the manufacture of firearms, which involves the processing of various parts of firearms. High-precision CNC machining technology can ensure the accuracy and quality of firearm parts.

- Surface Treatment technology: Surface treatment technology refers to the treatment of the surface of firearm parts to improve their corrosion resistance, wear resistance and aesthetics. Common surface treatment techniques include anodizing, electroplating, and spraying.

- Assembly And Quality Control: Assembly is the combination of the various parts of a firearm into a complete product. During the assembly process, manufacturers need to conduct strict quality control to ensure the performance and safety of each firearm.

In the design of the firearm structure, we also need to consider the following aspects:

- Buttstock design: The buttstock is the supporting part of the firearm, which directly affects the shooter’s comfort and shooting stability. The design of the gun stock should fully consider the principles of ergonomics, adapt to the body shape and posture needs of different shooters, and at the same time have good anti-skid performance and shock absorption effect.

- Design of the upper unit: The upper unit is an important part of the firearm, including the barrel, aiming device, guide rail and other components. The design of the upper unit needs to ensure the precise cooperation between the various components, improve the shooting accuracy and reliability, and at the same time have a certain degree of versatility, which is convenient for the shooter to customize and modify according to actual needs.

- Ammunition supply system design: The ammunition supply system is responsible for delivering bullets to the chamber of the firearm, which affects the burst performance and ease of use of the firearm. The design of the ammunition supply system should take into account factors such as ammunition capacity, ammunition supply speed, and the convenience of changing ammunition to ensure that it can meet the shooter’s needs in various combat environments.

- Safety system design: Firearm safety system is an important guarantee to prevent misfire and illegal use. Security systems should be designed to be simple and easy to use, allowing the shooter to quickly unlock them in an emergency. At the same time, the safety system should also have certain protective performance to prevent the firearm from being damaged in an accidental situation.

The Application Of 3D Printing Technology In Gun Manufacturing

3D printing has revolutionized firearms manufacturing by producing high-quality firearm components quickly and cost-effectively. With the continuous maturity of 3D printing technology, future firearms manufacturing will be more efficient and flexible. Specifically in the following aspects:

- Rapid prototyping: 3D printing technology can quickly manufacture physical parts based on digital models, which means that for firearms designers, they can quickly verify design solutions in a short period of time and accelerate the process of product development.

- Customized production: 3D printing technology has high flexibility and can easily realize single-piece production and small batch production. This enables firearms manufacturers to customize the production of firearms for specific needs and meet the individual needs of different users.

- Manufacture of complex structures: 3D printing technology can easily manufacture complex structures that are difficult to achieve with traditional manufacturing processes, which provides more design freedom for firearms designers and can design more high-performance firearms components.

- Saving materials and reducing costs: Compared with traditional manufacturing processes such as cutting and casting, 3D printing technology has a higher material utilization rate and can greatly save material costs. In addition, 3D printing technology can also reduce energy consumption and environmental pollution in the production process.

The design and manufacture of firearms is an ever-evolving field, and the application of new technologies, new materials and new concepts will continue to promote the progress of firearms manufacturing. Facing the future, gun manufacturing will pay more attention to efficiency, intelligence and environmental protection, and provide humans with safer and more reliable gun products.

Introduction: The Intersection of CNC Technology and Firearms Production

Computer numerical control (CNC) machining has revolutionized modern manufacturing by automating intricate processes, resulting in enhanced precision, efficiency, and scalability. This technology has found application in various industries, from aerospace to electronics. Paradoxically, CNC machining’s potential to aid in firearms production raises questions about its ethical implications, particularly in countries like China, where government policies and international norms often intersect.

The Legal Framework – Navigating International Restrictions

International Arms Trade Agreements and Embargoes:

A cornerstone of global security, arms trade agreements seek to prevent weapons proliferation. China, as a signatory to several international treaties, is bound by regulations that restrict its participation in the arms trade.

Dual-Use Technology Conundrum:

CNC machinery is dual-use technology, with applications spanning both civilian and military domains. This blurring of lines poses challenges for China’s CNC suppliers, who must tread carefully to avoid violating international agreements.

The Ethical Quandary – Balancing Innovation and Responsibility

Moral Considerations in Firearm Production:

The production of firearms raises ethical questions concerning their use, potential for harm, and contribution to conflict. China’s CNC suppliers grapple with these ethical dilemmas when considering gun machining.

Public Backlash and Reputation Management:

Companies today are acutely aware of their public image. Engaging in firearm manufacturing, even indirectly, could attract negative attention and harm a company’s reputation and market standing.

Economic Complexities – Weighing Profit and Sustainability

Commercial Viability of Firearms Production:

While firearms manufacturing might yield profits, China’s CNC suppliers must evaluate the long-term sustainability of such ventures. Economic instability resulting from fluctuations in global demand, legal challenges, and shifting consumer preferences could undermine potential gains.

Diversification vs. Specialization:

Many CNC suppliers have found success in diversifying their product offerings. Engaging in firearms production might divert resources and attention from existing, lucrative markets.

Geopolitics and Diplomacy – China’s Global Standing

China’s International Image:

China’s rise as a global economic power has been accompanied by a concerted effort to project a responsible and cooperative image on the international stage. Involvement in firearm manufacturing could contradict this image and raise suspicions among trading partners and allies.

Impact on Bilateral Relations:

Engaging in firearm production could strain diplomatic relationships with countries that have strict regulations or moral objections to the arms trade.

The Role of Technology Transfer Controls

Regulating Technology Transfers:

China’s government regulates the transfer of sensitive technologies, including CNC machinery, to prevent potential misuse. These controls aim to strike a balance between technological progress and national security.

Unintended Consequences:

Imposing strict technology transfer controls could inadvertently hinder China’s industrial growth and hinder innovation, affecting sectors unrelated to firearms.

Conclusion: Navigating the Path Ahead

The complex decision by China CNC machining suppliers to refuse gun machining reflects the intricate web of legal, ethical, economic, and geopolitical factors that govern modern manufacturing. While the allure of profits might be strong, the potential consequences of engaging in firearm production compel these suppliers to weigh their options meticulously. The case of China sheds light on the broader discussion surrounding technology, responsibility, and the multifaceted nature of contemporary global manufacturing.

By understanding the motivations and complexities behind this refusal, we gain insights into the intricate dance between technology, regulation, morality, and the future of CNC machining on a global scale. As the world continues to grapple with these challenges, the case of China’s CNC suppliers and their stance on gun machining stands as a testament to the evolving landscape of modern industry.