SPWM (Sinusoidal Pulse Width Modulation) is a modulation technique used in power electronics to control the output voltage of inverters and voltage-regulated power supplies.

It is widely employed in various applications, including motor drives, uninterruptible power supplies (UPS), and renewable energy systems. The principle of SPWM involves generating a series of pulses with varying widths to approximate a sinusoidal waveform.

Here’s a detailed explanation of the SPWM modulation principle:

Sinusoidal Reference Signal

The SPWM technique starts with a sinusoidal reference signal, which represents the desired output voltage waveform. The frequency of this reference signal typically corresponds to the fundamental frequency of the output voltage required by the application.

Carrier Signal

The carrier signal is a high-frequency triangular waveform that serves as the carrier for the modulation process. Its frequency is usually much higher than the frequency of the sinusoidal reference signal. The carrier frequency determines the resolution of the output waveform and affects the harmonic content of the output voltage.

Comparison Process

In SPWM, the sinusoidal reference signal is continuously compared with the carrier signal. At each moment in time, the magnitude of the sinusoidal reference signal is compared with the instantaneous value of the carrier signal.

Pulse Width Modulation

The comparison process results in the generation of pulses with variable widths. When the instantaneous value of the carrier signal is lower than the magnitude of the sinusoidal reference signal, the corresponding output pulse is set to high. When the instantaneous value of the carrier signal is higher than the magnitude of the sinusoidal reference signal, the corresponding output pulse is set to low.

Variable Duty Cycle

The width of the generated pulses, also known as the duty cycle, varies based on the comparison between the carrier signal and the sinusoidal reference signal. The larger the difference between the two signals, the wider the pulse width will be.

Low-Pass Filter

The output of the SPWM modulation process contains a high-frequency component due to the carrier signal. To obtain a pure sinusoidal waveform, a low-pass filter is used to filter out the carrier frequency and its harmonics, leaving only the fundamental frequency component.

Output Voltage Replication

By controlling the duty cycle of the generated pulses, the SPWM modulation replicates the shape of the sinusoidal reference signal. As a result, the average voltage of the output waveform follows the desired sinusoidal voltage.

The SPWM modulation principle allows for precise control of the output voltage waveform, making it possible to generate high-quality sinusoidal voltage signals even in applications where accurate voltage regulation is required. It offers efficient utilization of power and reduced harmonic distortion, making it an excellent choice for various power electronics applications.

SPWM adopts the principle of sinusoidal pulse width modulation, which has the advantages of high power factor and good output waveform, and is widely used in AC speed control systems.

Working Principle Of Single-Phase Inverter Bridge

The single-phase inverter bridge circuit consists of four inverter transistors VT1~VT4. P|N is the DC bus voltage terminal, and the input DC voltage is E.

It is stipulated that the a terminal is “+” and the b terminal is “-“, the output voltage Unb; otherwise, the output voltage is “-“. In the first half cycle, the control signal makes VT1 and VT4 turn on, while VT2 and VT3 turn off, at this time Uab=+E. In the second half cycle, the control signal makes VT2 and VT3 turn on, while VT1 and VT4 turn off, at this time Uab=-E. This cycle is repeated, and the AC voltage Uab is output at both ends of a and b.

Working Principle Of Three-Phase Inverter Bridge

Three-phase inverter bridge circuit structure, the circuit is composed of six power transistors VT1~VT6, U, V, W are the output ends of the inverter bridge.

By alternately turning on and off the six switches VT1~VT6, three-phase six-current current with a phase difference of 120 degrees can be obtained at the output end. By changing the order in which any two power transistors are turned on and judged, the phase sequence of the three-phase six-current can be changed.

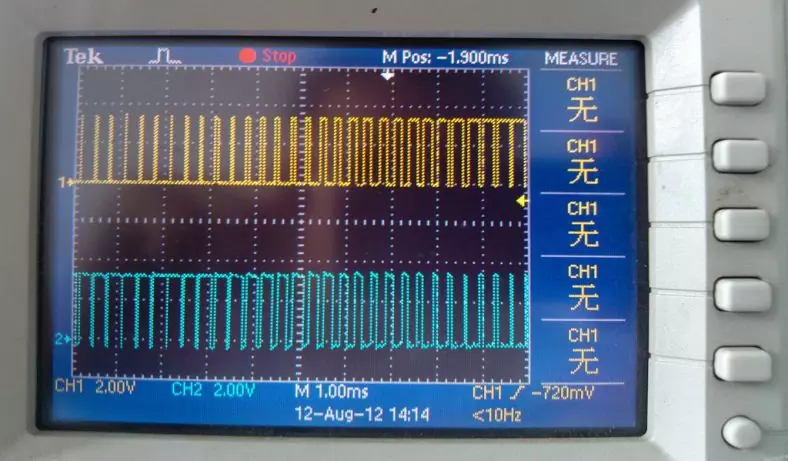

Working Principle Of Sine Wave Pulse Width Modulation

PWM is to adjust the amplitude of the output voltage by changing the width of the output voltage pulse when the amplitude of the pulse voltage is constant. Sine wave pulse width modulation is to use the intersection of sine wave and triangle wave to obtain a group of rectangular pulses whose pulse width changes according to the sine law. Using this group of rectangular pulses as an inverter, a group of DC voltages can be obtained at the output of the inverter. A pulse voltage whose amplitude is E and whose width varies sinusoidally.

When the amplitudes of the sine reference waves Ua, Ub, and Uc are greater than the amplitude of the modulating triangular wave U1, the output is 1; otherwise, the output is 0.

By changing the frequency fc and amplitude Uc of the reference sine waves ua, Ub, Uc, the output fundamental voltage frequency f1t and amplitude U1 can be changed; By changing the frequency of the modulating triangular wave U1, the output pulse width and period can be changed.

It should be noted that the ratio of the amplitude U1 of the fundamental voltage output by the inverter to the DC side bus voltage E is numerically equal to M. This is the essence of VVVF (the complicity of the output voltage and the adjustable frequency of the output voltage) using PWM

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!