When it comes to 3D printing, there are a lot of moving parts. Obviously, having the best 3D printer is all well and good, but did you know that you also need specific software to make 3D models ready to print? These programs are called slicers, and they’re a must for making, um, 3D printing indispensable.

What Is 3D Printing Slicer?

In the context of 3D printing, a slicer is a software tool used to convert a 3D model into instructions that can be understood by a 3D printer. It takes a digital 3D model file, typically in a format such as STL or OBJ, and slices it into a series of 2D layers that the 3D printer can understand and fabricate.

The primary function of a slicer is to determine the printing parameters for each layer of the 3D model. This includes settings such as layer height, print speed, extrusion width, infill density, support structures, and more. These settings can be adjusted based on the desired print quality, strength, and other requirements.

How Does a 3D Slicer Work?

A 3D slicer works by taking a 3D model and converting it into a series of instructions that a 3D printer can understand and execute. Here is a step-by-step explanation of how a typical 3D slicer works:

Importing The 3D Model

Slicing The Model

Generating Toolpaths

Configuring Print Settings

Generating Support Structures

Generating G-code

The G-code file can be saved to an SD card or USB drive, or transferred directly to the 3D printer. The printer reads the G-code instructions and executes them, following the precise instructions provided by the slicer to create the physical object layer by layer.

By performing these steps, a 3D slicer transforms a digital 3D model into a set of instructions that a 3D printer can use to build the physical object. Different slicer software options offer various features, settings, and customization options to achieve desired print outcomes.

What Are the Features of 3D Slicers?

3D slicers offer a variety of features to enhance the 3D printing process and provide users with greater control over their prints. Here are some common features found in slicer software:

- Layer height and print settings: Slicers allow users to adjust the layer height, which determines the thickness of each printed layer. They also provide settings for print speed, extrusion width, infill density, and other parameters that affect the print quality, strength, and speed.

- Support structures: Slicers have the ability to generate support structures automatically or manually. These structures are temporary supports printed alongside the main object to provide stability for overhangs or complex geometries during printing. Support structures can be customized based on parameters like density, placement, and ease of removal.

- Infill patterns: Slicers offer various infill patterns that determine the internal structure of the printed object. Infill affects strength, weight, and material usage. Common infill patterns include grid, honeycomb, triangular, and gyroid, among others. Users can adjust the infill density to control the amount of material used.

- Print preview and simulation: Slicers provide a visual preview of the sliced model before printing. This allows users to see how the layers will be printed and identify any potential issues or areas for optimization. Some slicers even offer simulation features to simulate the printing process virtually, giving users a realistic view of how the object will be built.

- Multiple extruders and materials: Slicers support multi-extruder printers, allowing users to assign different extruders to specific parts of the model. This enables the printing of objects with multiple colors or using different materials. Slicers provide options to assign extruders, define tool changes, and set material-specific settings.

- Customizable supports and rafts: Slicers enable users to customize support structures and rafts. They allow for adjusting support parameters such as support density, contact points, overhang angle threshold, and support pattern. Rafts provide a base for better adhesion and can be customized with parameters like thickness, air gap, and pattern.

- Print time estimation: Slicers can estimate the time required for printing a model based on the chosen settings, print speed, and other factors. This feature helps users plan their printing schedule and manage their workflow effectively.

- G-code customization: Slicers allow users to manually modify the generated G-code instructions. This advanced feature enables experienced users to fine-tune the print settings and adjust specific parameters directly in the G-code, providing greater control over the printing process.

- Printer compatibility: Slicers are designed to support various 3D printers, and they often have pre-configured profiles for popular printer models. They allow users to select the appropriate printer and load specific settings for optimal compatibility and performance.

Types of 3D Printing Slicer – Best 3D Slicer Software

There are several types of 3D printing slicer software available, each with its own set of features and capabilities. Here are some popular 3D slicer software options:

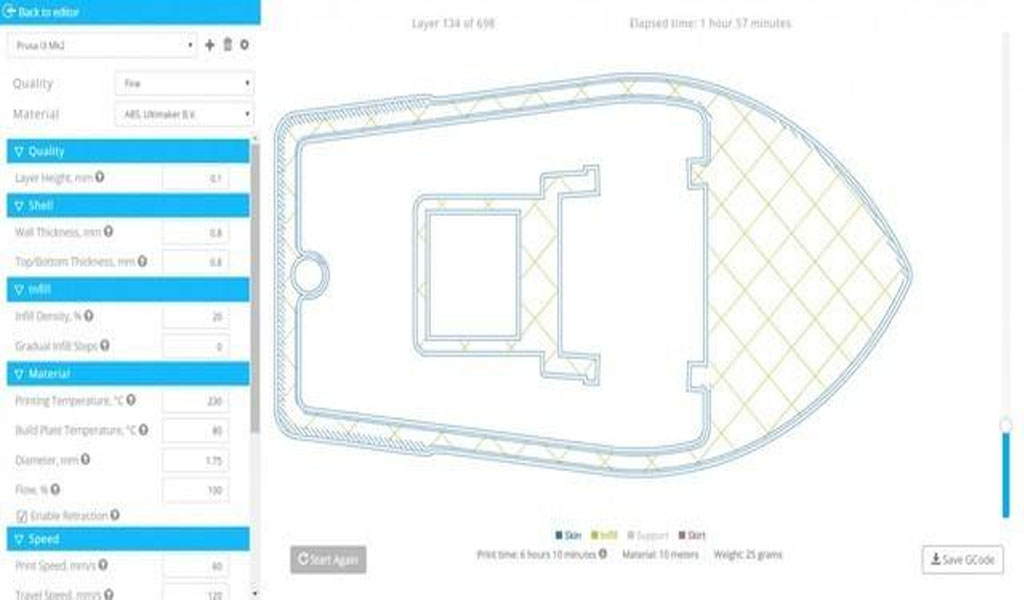

- Ultimaker Cura: Cura is a widely used open-source slicer software known for its user-friendly interface and powerful features. It supports a wide range of 3D printers and offers extensive customization options for print settings, support structures, infill patterns, and more. Cura also provides a print preview and simulation feature for visualizing the printing process.

- PrusaSlicer: Developed by Prusa Research, PrusaSlicer is another popular open-source slicer software. It offers advanced features such as customizable supports, variable layer height, sequential printing for multi-material prints, and different infill options. PrusaSlicer is highly regarded for its compatibility with Prusa 3D printers, but it also supports other printer models.

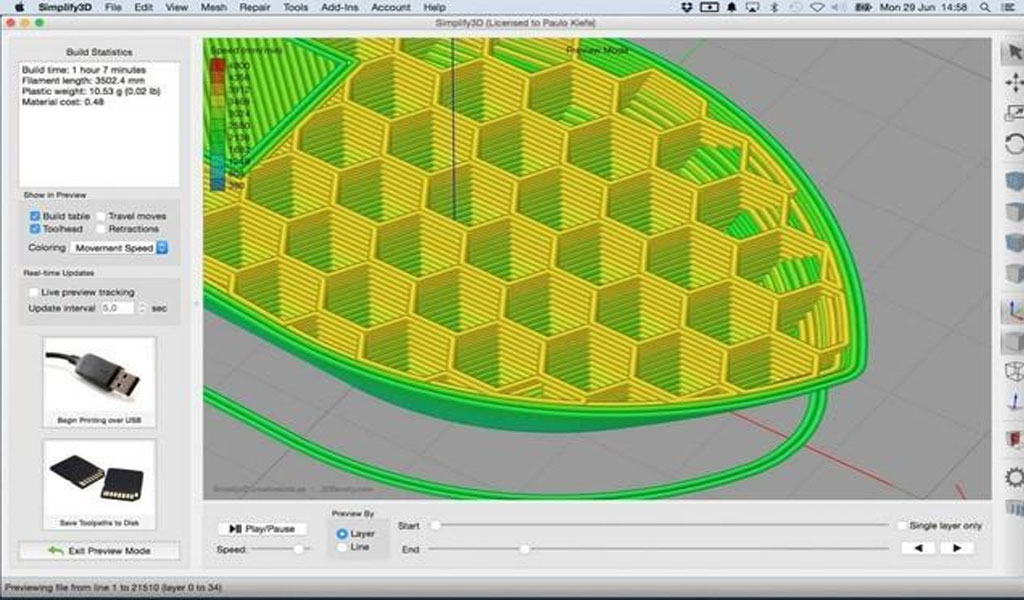

- Simplify3D: Simplify3D is a commercial slicer software known for its comprehensive feature set and advanced customization options. It supports a wide range of 3D printers and offers features like multi-material printing, custom support structures, variable layer heights, and optimized print paths. Simplify3D also provides detailed control over print settings and has a reputation for producing high-quality prints.

- Slic3r: Slic3r is an open-source slicer software known for its robust capabilities and continuous development by the 3D printing community. It offers features such as customizable support structures, infill patterns, and multiple print profiles. Slic3r is often used in conjunction with Prusa printers but is compatible with various other printer models as well.

- PrusaSlicer PE (Prusa Edition): PrusaSlicer PE is a modified version of PrusaSlicer specifically tailored for Prusa 3D printers. It offers enhanced features and settings optimized for Prusa printers, including auto bed leveling, mesh bed leveling, and Prusa-specific print profiles. PrusaSlicer PE is recommended for users who primarily use Prusa printers.

- IdeaMaker: IdeaMaker is a slicer software developed by Raise3D. It offers a user-friendly interface and supports a range of 3D printers. IdeaMaker provides advanced features like customizable support structures, variable layer heights, and multi-part printing. It also includes a built-in library of print profiles for various printer models.

The choice of the best 3D slicer software depends on individual preferences, specific requirements, and compatibility with the 3D printer being used. It’s recommended to explore different slicer software options and experiment with their features to find the one that suits your needs and workflow the best.

3D Slicing Software List For Desktop FDM Technology

Everyone wants to get the best printing effect from the 3D printer around him. In addition to design optimization, 3D printer and printing materials, there is a more important link is the slicing software, which plays an important role in the printing results. , we can understand slicing software as a tool for converting and driving from digital models to physical models.

The following lists 19 3D slicing software tools for desktop-level FDM 3D Printing technology in 2023, some of which I have used, such as Cura, HORI 3D printing slicing and control system, Flashforge FlashPrint, Simplify3D, Makerbot print, etc. Most of them are It was used when testing the 3D printing of FDM technology in the past, because many slicing software have corresponding hardware, and of course some software is general-purpose, giving users very good personalized setting parameters. After many years of iterations Optimization, most of the 3D printing slicing software are doing well now, but there are some differences in user positioning and functions. Some software positioning is for beginners, so the setting of many parameters will be very simple, the setting options There are also fewer, and some software is for professional users, and there are many parameter options that can be set, including nozzle temperature, bottom plate temperature, speed, layer thickness, layer gap, material diameter, etc., and some software supports Cloud slicing, model restoration and design have relatively large functional differences.

The process of 3D printing consists of several basic elements. First of all, you need to have a 3D model and a 3D printer, as well as a 3D printing slicer software, which acts as an intermediate drive and path planning and calculation link between the 3D model and the 3D printer.

Model Printed Without Supports

Friends who have used 3D printers know that the 3D printing slicer prepares the selected model for your 3D printer and generates Gcode files. Some hardware manufacturers’ slicing software will generate a file in a special format, such as MakerBot’s .x3d, and the Gcode code It is a numerical control (NC) programming language with good versatility.

FDM 3D Printers Can Also Produce Perfect Results

But for now, let’s start using the best 3D slicing software tools to work with 3D printers, and it has become a trend to optimize setting parameters for design and model, which can also be understood as process optimization for FDM technology.

To evaluate a slicing software, judge from the experience, you can evaluate it from the following dimensions: SLT file import and slicing efficiency, whether the repair function is powerful, whether the printing parameter options are rich enough, model and printing information display, support for different The printer still only supports one brand of printer, supporting functions, final output of the model, printing efficiency, etc.

Today, BE-CU uses the following 19 slicing software to start a discussion, to understand the current mainstream 3D printing slicing software in the world, and then make the final printing more stable and the output result more perfect through continuous use. Below I divide the collected 19 slicing software into five categories to share.

1.3DPrinterOS

3DPrinterOS is a cloud-based platform slicing software that integrates the different components necessary for 3D printing. Connect the 3D printer to the computer like a normal inkjet or laser printer, and open it from a browser or desktop software. In addition to slicing, 3DPrinterOS also includes different options to repair the mesh of the model. This function is only available in a few slicing software. If you want to repair the model professionally, you still need to use professional model repair software such as magics. Users can download it from Sketchfab.com The model is printed by a printer, but some advanced functions of this software are charged. The good news, though, is that the company promises that slices will always be free.

There are three 3D printer slicing applications integrated into the 3DPrinterOS standard 3D slicer software, namely “Cloud Slicer”, “Slicer 2” and the dedicated “Makerbot Slicer”. 3DprintOS supports a wide range of 3D printers, which can meet the needs of commercial solutions.

“Cloud Slicer” and “Makerbot Slicer” are almost identical in interface and function. As with other professional 3D slicing software tools, users can choose between different levels of complexity (simple, advanced and expert). However, there is a function that most FDM slicing software does not have, which is to estimate the price of the printed model, so it is more suitable for users who do printing services.

The software interface of “Slicer 2” is different from the previous two: users can customize multiple preset lists to precisely control printing, or manually configure printing parameters from scratch, with better flexibility and functionality, similar to cura and simplify3D .

- Features: There are three different slicing systems to provide users with slicing options, which can repair the model to a certain extent.

- Disadvantages: Advanced features require a fee to enable them.

- 3DPrinterOS download link: https://www.3dprinteros.com/

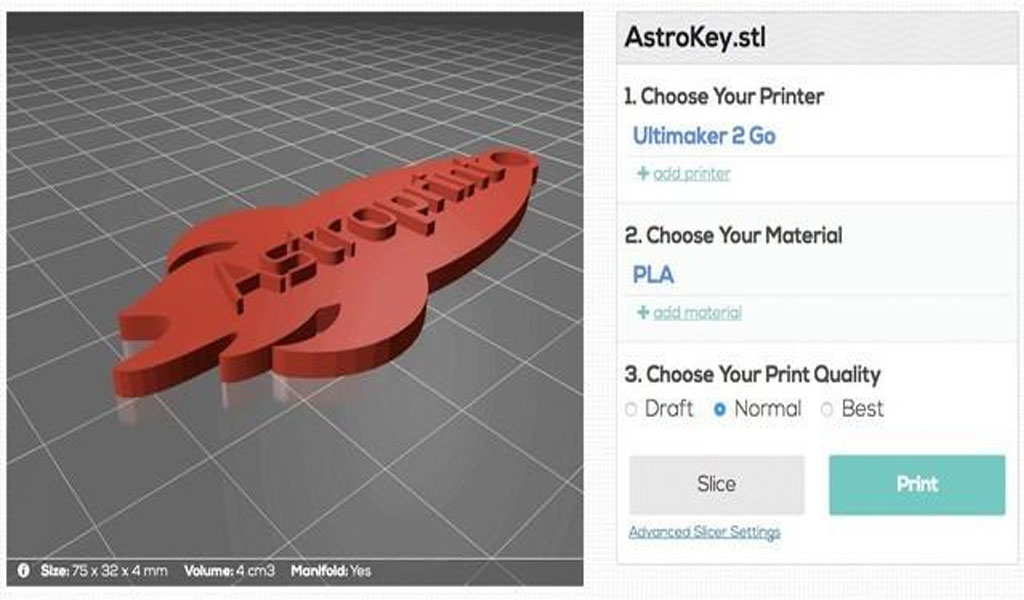

2.Astroprint

Astroprint is also a cloud-based slicing software with a design concept similar to 3DPrinterOS and Octoprint. 3D printers are implemented with a specialized device called the Astrobox (basically a Raspberry Pi). Users can monitor and control your printers from any web-enabled device in the world.

If the user does not have a 3D model to print, it can be downloaded from a web service such as the search engine Yeggi, the repository CGTrader or Thingiverse. It is also possible to design 3D models from scratch in the web-based 3D modeling tools 3DSlash and Leopoly. If the user’s 3D model cannot be printed correctly, Astroprint can be connected to 3DPrintCloud to fix it. If users do not have their own 3D printer, they can also print model files through i.materialize.

The Astroprint3D Slicer software itself is very simple. In simple mode, the user can select the material and print quality. At the same time, the software has an advanced mode for professional players.

- Features: Many web services are integrated, which is an excellent way to explore the world of desktop 3D printing.

- Disadvantages: The 3D slicing software function is hidden in the file manager and will not be listed in other options such as downloads. You must click the small preview rendering of the 3D model to go to the slicing function.

- Astroprint download link: https://www.astroprint.com/

3.SliceCrafter

SliceCrafter is an online 3D slicing software that supports Mac users. Users cannot edit OpenSCAD codes. The slicing function is roughly the same as IceSL. Users can upload STL files through web links.

- Features: Users can generate GCode without installing 3D slicing software, and support online services.

- Disadvantages: Does not support desktop applications and has fewer functions.

- SliceCrafter download address: http://shapeforge.loria.fr/slicecrafter/

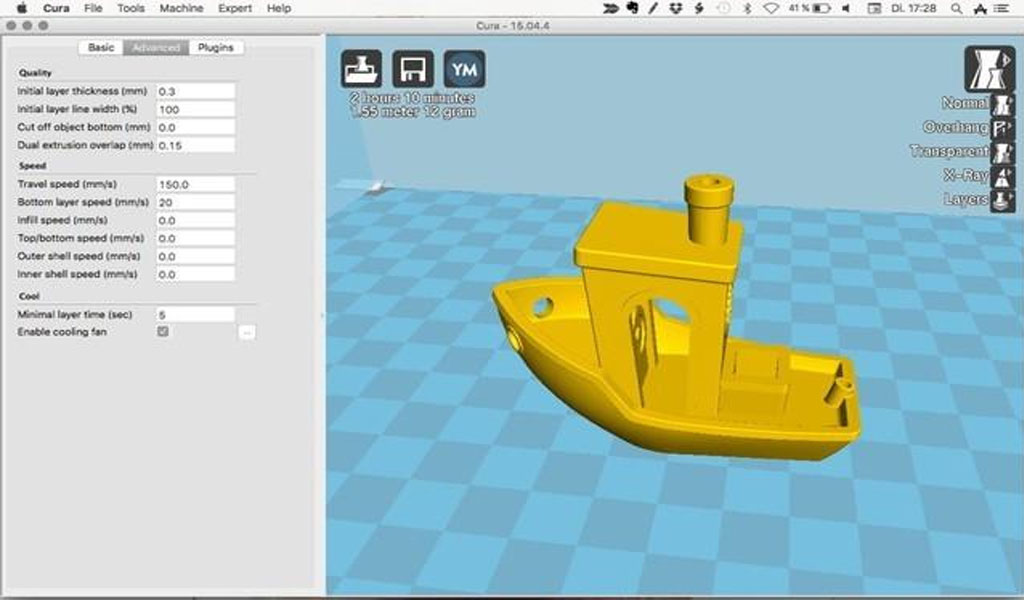

4.Cura

Cura is developed and maintained by 3D printer company Ultimaker and its community. Cura itself is derived from open source. The 3D printing slicing software is free, and it is also a slicing software with a very high penetration rate in the industry. In the early days, many domestic 3D printing manufacturers also used Cura as a slicing function. We can see that Cura has even added configuration files for competitors’ 3D printers, and its open source and open attitude is very clear, which has also benefited many users.

Cura supports STL, 3MF and OBJ file formats, also supports file repair, supports display of print head path, printing time and material usage.

- Features: Cura is not only suitable for beginners, but also suitable for professional players. The most important settings are more intuitive. For professional players, there are more than 200 settings to choose from, supporting dual-head dual-material printing. Cura’s slicing efficiency is relatively high, and it can quickly process large STL files.

- Insufficient: The printing time estimation is not accurate enough, sometimes it will be reduced by about 10-20%.

- Cura download address: https://ultimaker.com/en/resources/manuals/software

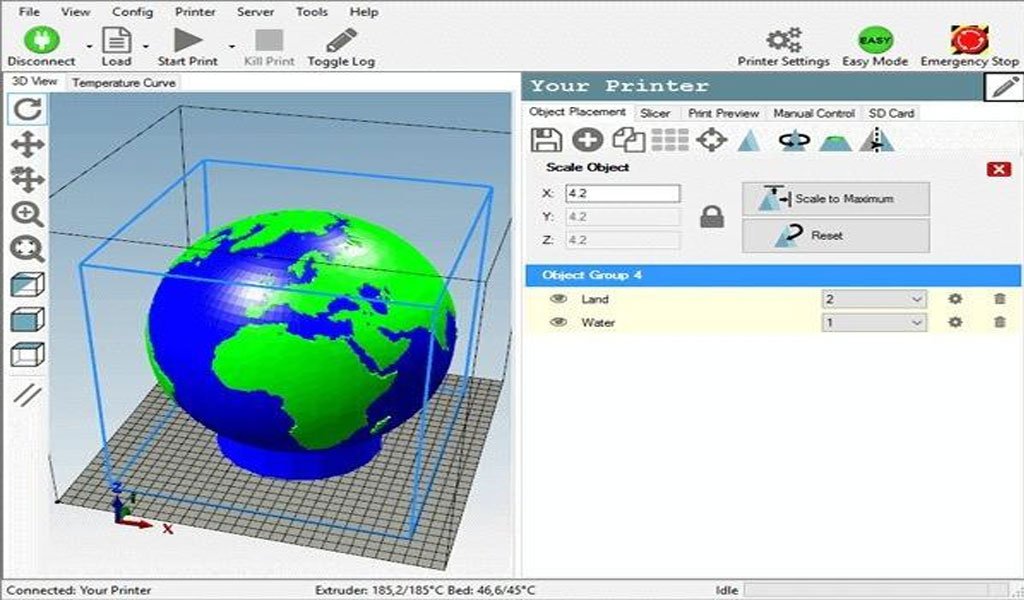

5.Repetier

In the open source 3D printing system, RepRap must be mentioned. Repetier is the slicing software of the open source system. The functional modules are more professional and suitable for advanced users. As an all-in-one solution, Repetier provides multi-extruder support, up to 16 extruders, multi-slicer support through plug-ins, and supports almost any FDM 3D printer on the market, provided that users upgrade frequently. Repetier Host also provides remote access through Repetier Server, which, similar to OctoPrint, can be installed on a Raspberry Pi so that the 3D printer can be accessed and controlled from anywhere through a browser on a PC, tablet or smartphone.

- Features: When MakerBot changed from open source to closed source, Repetier open source 3D slicing software became one of the favorite software for makers.

- Insufficient: To upgrade and update frequently.

- Repetier download link: https://www.repetier.com/

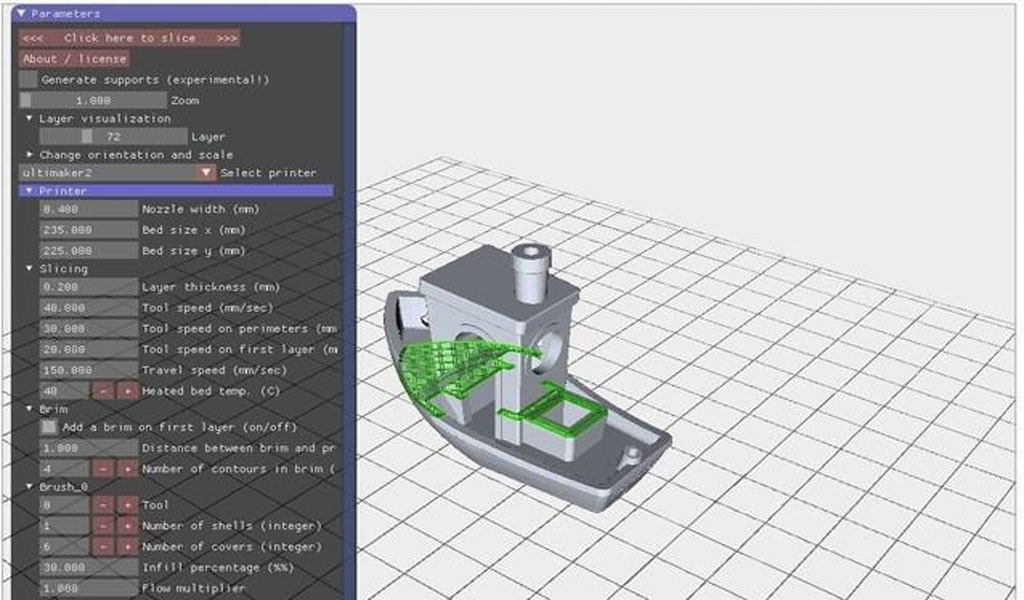

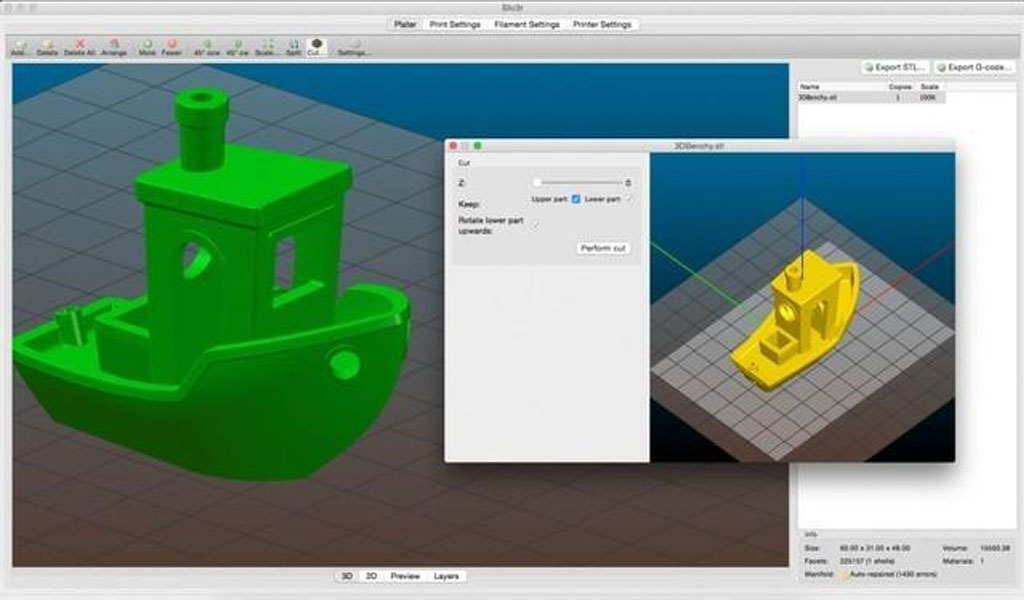

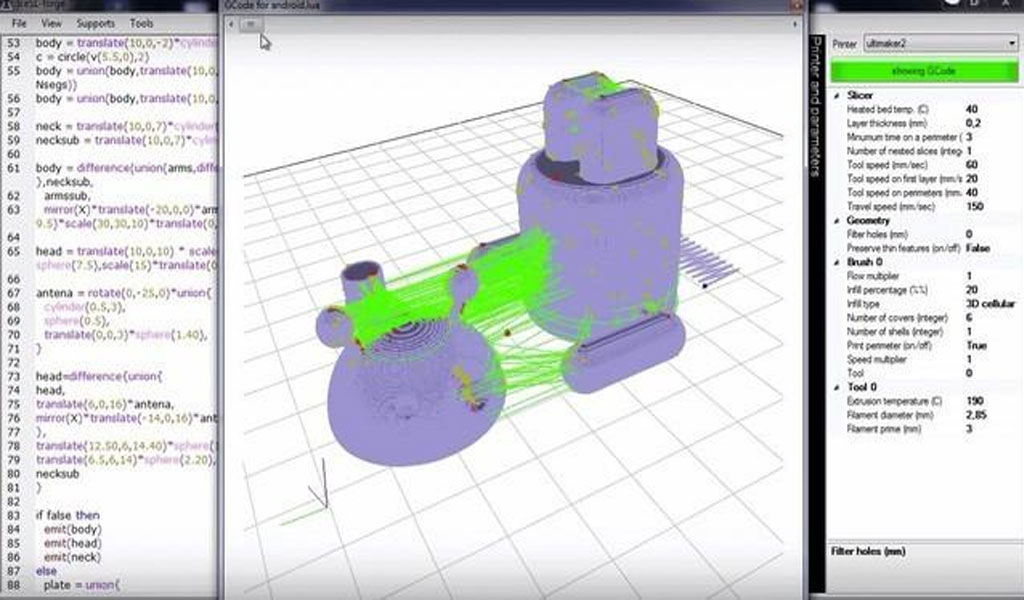

6.Slic3r

Slic3r is an open source 3D slicing software with advanced functional support. This 3D printing software includes multiple views so that users can better preview how the model will be printed.

In the infill setting, Slic3r supports a new honeycomb infill design, created in three dimensions, the infill pattern can cross layers instead of repeating the same pattern, which can greatly increase the strength of internal infill and final printing.Another feature of Slic3r is direct integration with OctoPrint. When files are sliced on the user’s desktop, they can now be uploaded directly into the user’s OctoPrint library with the click of a button.Slic3r has accumulated many years of 3D printing settings, materials and 3D printer matching problems. Many new functions of slicing software are derived from Slic3r, such as multiple extruders, edges, microlayers, bridge detection, command line slicing, variable Layer heights, sequential printing, honeycomb filling, mesh cutting, model cutting, and more.

- Features: Too many functions, supports real-time 3D slicing, even if the performance of the computer is mediocre, the slicing is quite fast. It includes real-time incremental slicing, 3D preview, 2D and 3D print head path preview, 3D honeycomb filling, customizable baseplate shape, integration with OctoPrint, pressure regulation and more.

- Cons: No print time and material estimates.

- Slic3r download address: http://slic3r.org/

7.Craftware

Another 3D slicing software developed in-house by 3D printer manufacturer Hungarian startup CraftUnique supports the company’s crowdfunded CraftBot 3D printer, but also other brands of 3D printers.

Like Cura, the CraftWare app can be switched between “easy” and “expert” modes. The visualization of the Gcode file is better, and each function is represented by a different color. But it is characterized by supporting personal management, and the slicing software with this function is currently charged.

This slicing software for 3D printers is still in beta and can experience bugs in everyday use.

- Features: The interface is beautifully designed. , fast and easy to use. When changing settings, you can see which parts of the print will change.

- Cons: There are bugs in the beta software.

- Craftware download address: https://craftunique.com/craftware

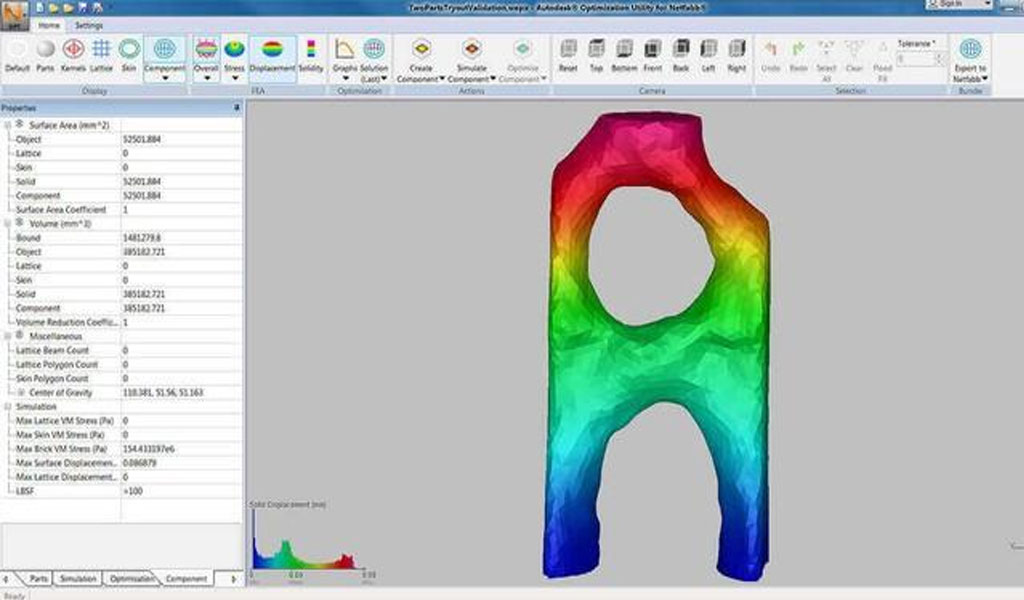

8.Netfabb Standard

The growth experience of Netfabb is quite special. It has been upgraded from the initial free software to a powerful toolkit for processing STL files. In addition to the powerful slicing function, users can analyze, repair and edit STL files before entering the slicing stage.

Autodesk acquired Netfabb in 2015, forming the three software we see now: Netfabb Standard, Netfabb Premium and Netfabb Ultimate, even the standard version is a very powerful 3D printing software.

- Features: Netfabb Basic is a real professional software for 3D printing, students can try the software for free for three years.

- Cons: Like all other Autodesk software, software pricing becomes a subscription. As of April 2017, users only have a 30-day free trial period, after which they need to pay to use it. The annual price for Standard is $1,000, and the Premium version will run you $4,300. The price of the premium version is not displayed on the website.

- Netfabb Standard download address: http://www.autodesk.com/products/netfabb/overview

9.SelfCAD

SelfCAD is a slicing and design software for the entire 3D printing workflow, including 3D model design functions.SelfCAD also provides hardware companies to design their own models for one-stop printing, and has built-in SelfCAD’s own slicing system

This software can slice newly designed models, has very advanced pre-print preparation controls, and all common parameter settings, such as layer height, infill density, print speed, etc.

- Features: After slicing, use the sliders to see a preview of each layer, showing estimated print time, material usage, and final model weight. In addition, the Spaghetti filling function can bring different effects and experiences to the model.

- Disadvantages: It is charged and does not support cloud slicing and cloud printing.

- SelfCAD download link: https://www.selfcad.com/

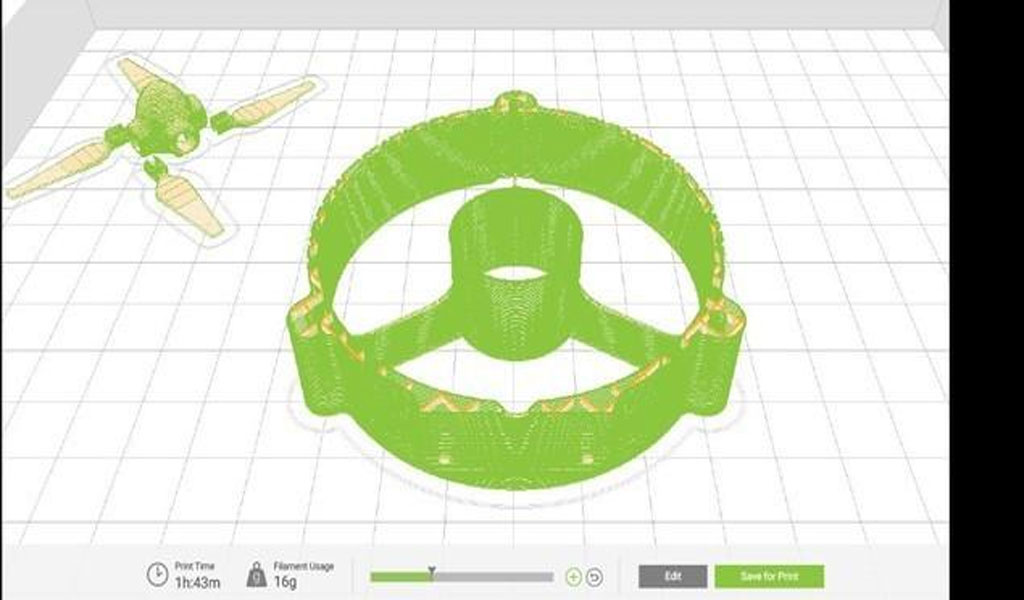

10.Simplify3D

The first time I came into contact with Simplify3D was when I tested makergear in 2016. It is a 3D slicing software for professional players and supports almost all available 3D printers. Users can download and import more than 100 3D printer configuration files, and users can add configuration files by themselves.

Simplify3D software allows users to import, scale, rotate and repair 3D models, STL, OBJ or 3MF file import is very fast, and even huge meshes can be displayed instantly.

Users can use rich settings: extruder, layer control, various filling methods, temperature and cooling settings, and even edit original G-code and scripts. These settings can be saved in the form of printing configuration files, which is convenient for calling and testing different parameter controls.

- Features: It can help professional players obtain the best model effect through parameter control, and the printing quality is excellent.

- Insufficient: The expensive price is a threshold for ordinary users, and the price of 2 computer licenses is 150 US dollars.

- Simplify3D download link: https://www.simplify3d.com/

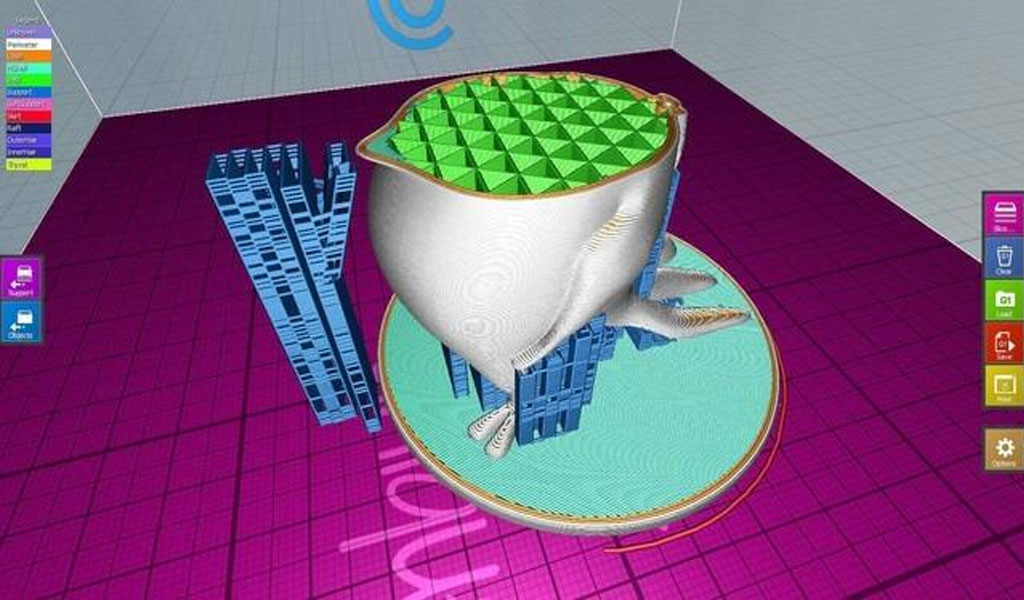

11.IceSL

IceSL is one of the best slicing software for 3D printing. It is not only 3D slicing software, but also 3D modeling. In the left window of the software interface, users can directly edit the model grid, which provides some ideas for many slicing software. In OpenSCAD, some beautiful parametric modeling functions can be realized.

In the middle of the software is the real-time preview interface of the model, and the functional area on the right can be used for various slice settings, which is not friendly enough for beginners. This software also supports two-color printing, and IceSL also has a soft material shield to protect the model from residual materials.

- Features: Support design features, programmers and makers may prefer IceSL’s amount of control.

- Insufficient: does not support mac OS system

- IceSL download link: https://members.loria.fr/Sylvain.Lefebvre/icesl/index.html

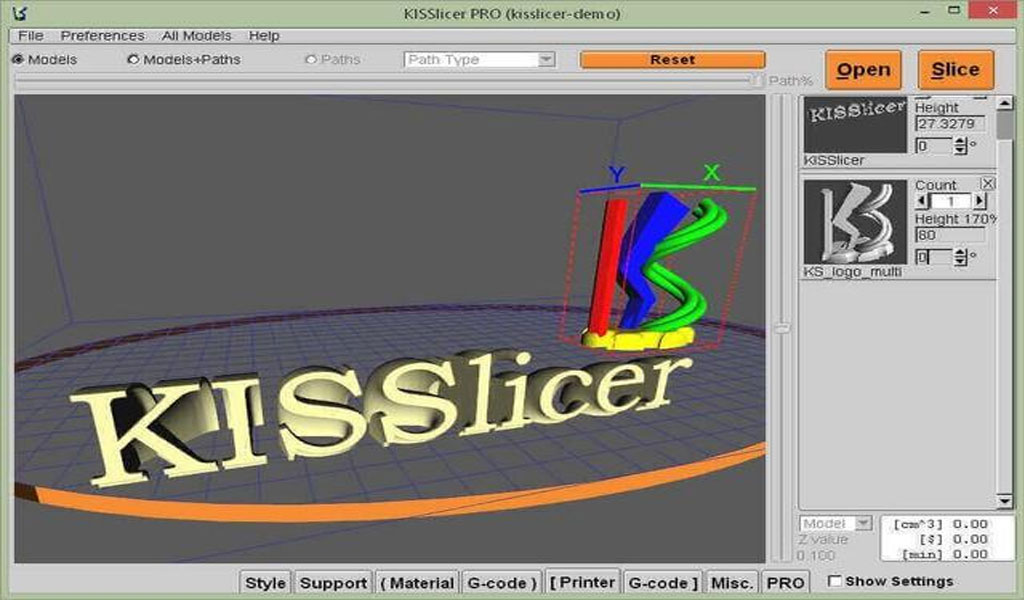

12.KISSlicer

KISS means “Keep It Simple Slicer”, the concept is very good, KISSlicer is a quite complex software. Some users like to use this slicing software when printing special models, because it can achieve perfect model surface and seam treatment, and some users do not like the interface of this software.

The free version of KISSliser is only suitable for amateurs who print with one print head, but the professional version can realize multi-head printing and has fewer setting options for generating Gcode. For advanced settings, users need to purchase the professional version, which supports merging multiple STL files into one printout.

- Features: It can replace most slicing software, and the model surface optimization and seam optimization are better.

- Disadvantages: This 3D slicer software supports most 3D printers on the market, but if there is no corresponding printer in the list, it needs to be invoked manually. Pro $35 (Business), $25 (Education)

- KISSlicer download link: http://kisslicer.com/

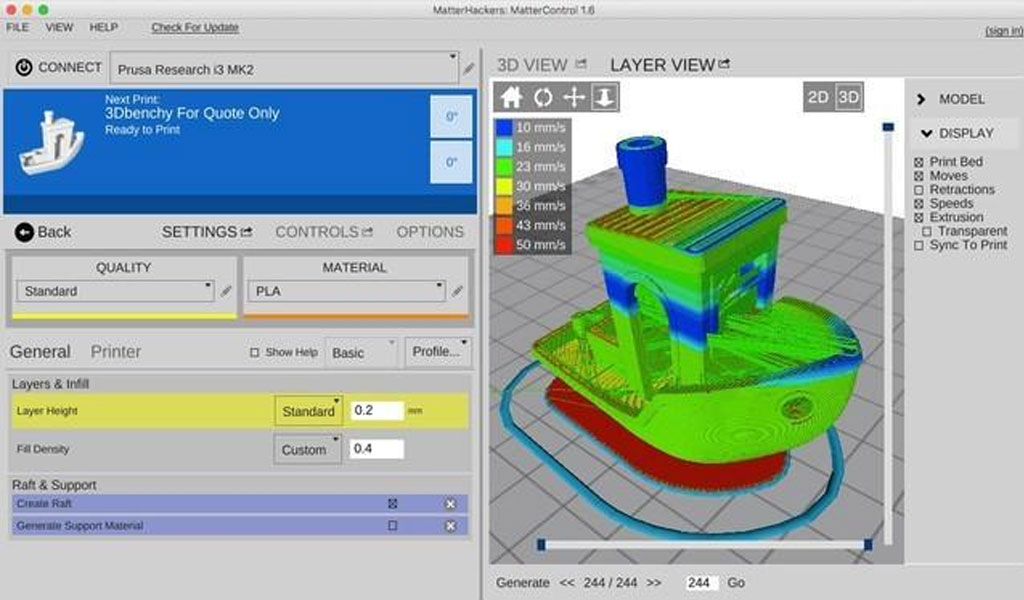

13.MatterControl

MatterControl’s 3D printing host is the user’s computer. The entire printing process needs to be connected to the computer, and it also supports Gcode files to be saved on the SD card. The software interface structure is very good. Users can reorder the print queue using the mouse, and prints can also be cut according to user preference.

MatterControl has three slicing engines (MatterSlice, CuraEngine and Slic3r), users can slice and compare print results. In basic mode, layer height, infill density, support material and raft can be adjusted, and saved settings are applied to continuous printing. It has automatic repair function and supports multiple print heads. In order to predict possible printing problems, users can preview the entire process layer by layer.

- Features: Three different slicing engines compare slicing results.

- Cons: The print quality is slightly inferior.

- MatterControl download link: http://www.mattercontrol.com/

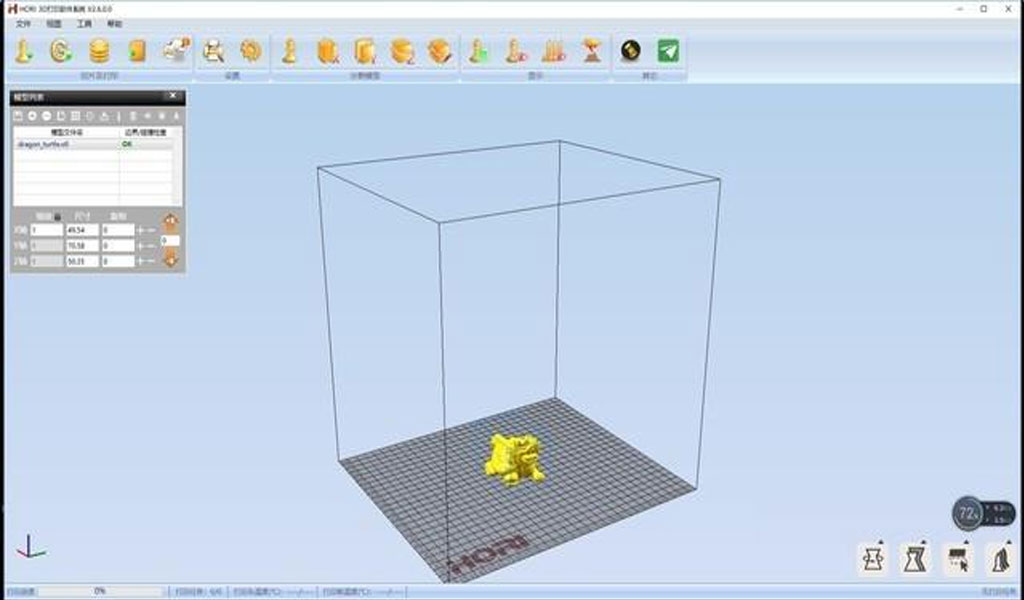

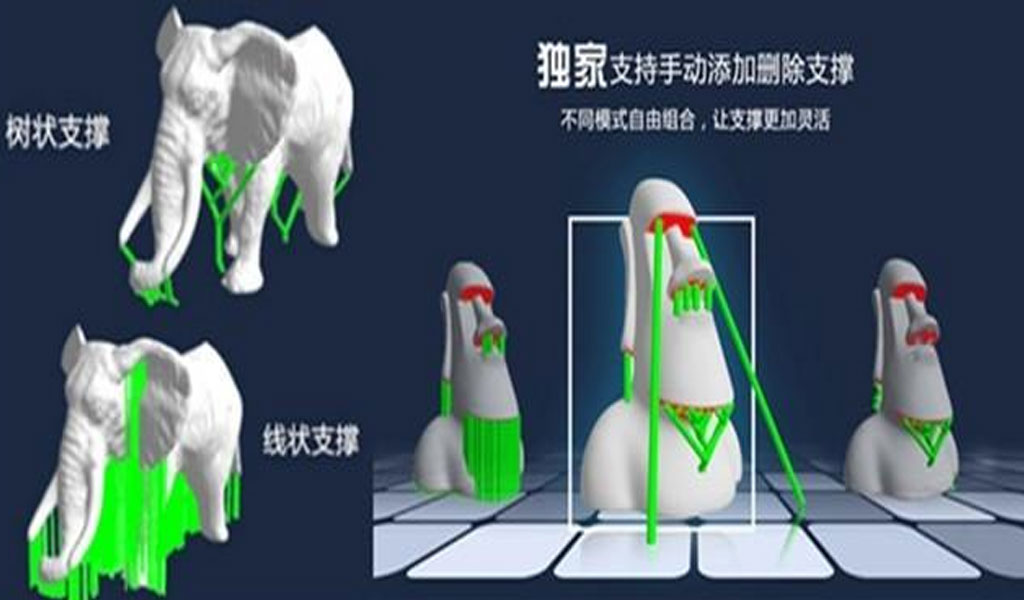

14.HORI 3D Printing

When testing the Hongrui MR300 at the earliest, I started to use the slicing software of Hongrui. Like most domestic first-line brands, I independently developed the slicing management software of the 3D printer. This software is composed of a slicing system and a printing control system, and the update iteration is continuous. , The picture style is simple, the operation is simple and easy to use. The software has breakpoint continuous printing and dual-nozzle printing mode, supports more than 90% of different brands of FDM and light-curing 3D printers in the market, and has all kinds of functions for model repair, cutting, manual support, shutdown and continuous printing, etc. English and other multi-language interface.

It is worth mentioning that the support structure supports optional linear, surface support, tree support, and column support; and allows users to freely create three-dimensional text (Chinese, English, Arabic numerals, special symbols, etc.).

- Features: The functions and optimization of the software continue to be sublimated, which is more in line with the usage habits of Chinese local users, and it is related to the domestic design software 3D one. Widely supports modeling, pictures and other files, has a user-friendly print management system, slice settings and its advanced factory mode, and feature-rich model editing.

- Disadvantages: Large-size and complex model slicing efficiency is low, waiting time is long, only supports windows system.

- HORI 3D print software download link: http://www.hori3d.com/Software

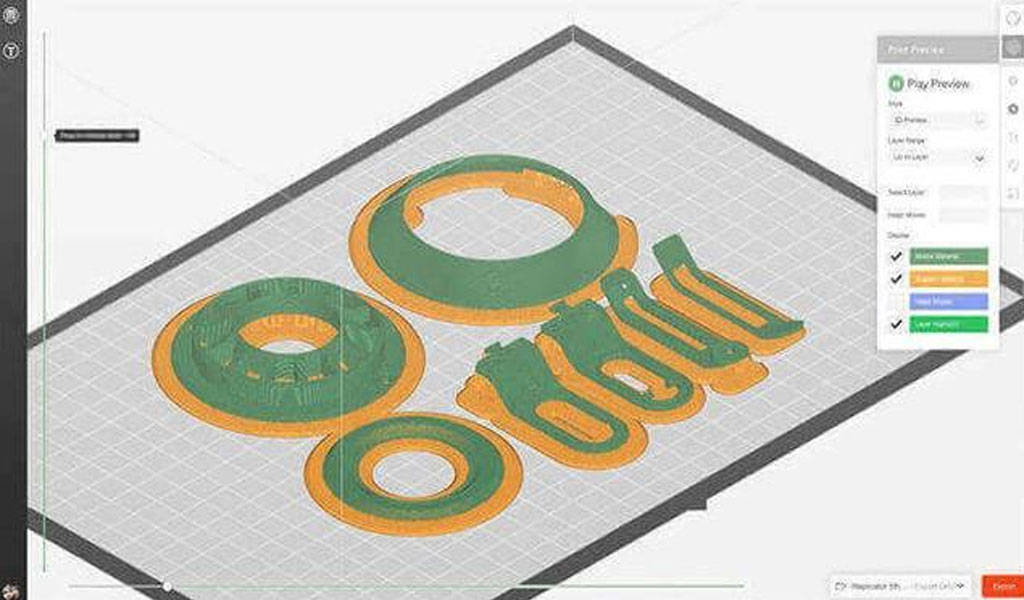

15.MakerBot Print

The early version of MakerBot Print is called MakerBot Desktop. This software is a slicing software dedicated to the MakerBot 3D printer series. Unlike the more versatile 3D printer slicing software, the MakerBot Print algorithm can automatically adjust the specific 3D printer mode and extruder type. Slicing settings.

There is a very useful feature that automatically arranges models on one or more build plates when preparing a series of components, and users can access and print Thingiverse objects from within the program. This program also has the function of OctoPrint: you can monitor and control the working status of the 3D printer through the built-in webcam of the printer.

- Features: Printing with MakerBot will get the highest quality of MakerBot printers, with better ease of use and higher efficiency in printing large-scale files.

- Disadvantages: It does not support other brands of 3D printers and has no versatility.

- MakerBot print download link: https://www.makerbot.com/print/

16.Tinkerine Suite

Tinkerine Suite is also a slicing software that I used when I tested Tinkerine’s 3D printer Ditto Pro. It is specially designed for Ditto and Litto series 3D printers, and it is called “the most user-friendly 3D slicing software”.

The user UI interface is really refreshing. This 3D slicing software is capable of basic editing and creating support structures for 3D models, allowing for quick selection of settings for Tinkerine 3D printers.

- Features: Simple and beautiful interface design Tinkerine Suite guarantees the best results for Tinkerine’s printers.

- Disadvantages: Similar to MakerBot, it is a closed-source system that only supports Tinkerine’s 3D printers.

- Tinkerine Suite download address: http://tinkerine.com/tinkerine-suite/

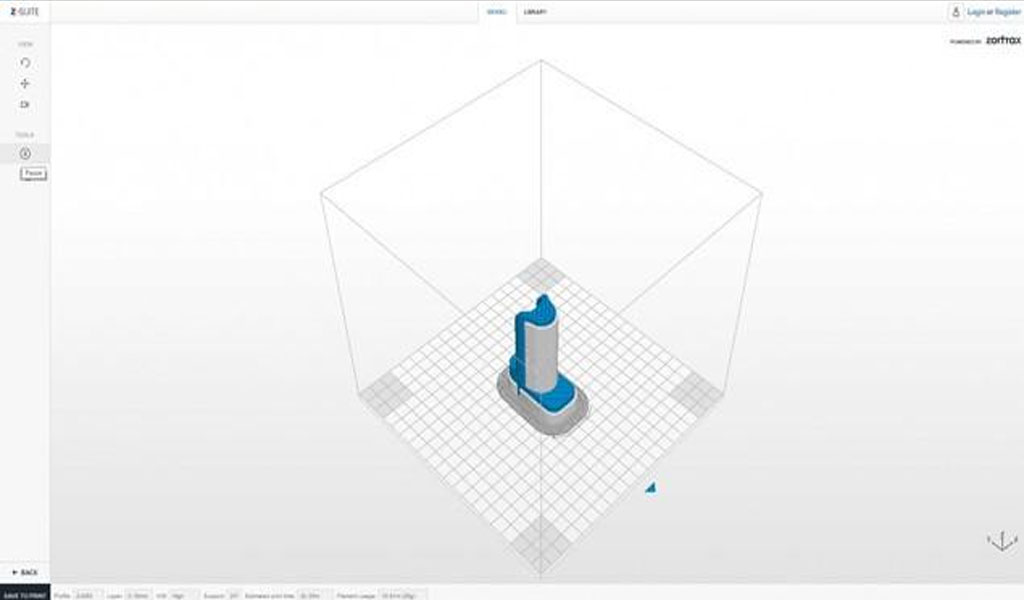

17.Z-Suite

The design concept of Z-Suite is basically the same as Tinkerine Suite. It is also a slicing software developed by Zortax, a 3D printer manufacturer. It has limited editing functions. The attached 3D slicing software can meet the basic slicing needs. The support structure is created, and finally the “Z-Code” file is produced.

- Features: Can you say there are no features?

- Disadvantage: Only one brand of 3D printers is supported.

- Zortax download address: http://support.zortrax.com/downloads/

18.FlashPrint

Flashforge’s FlashPrint software supports Flashforge’s 3D printers. It is independently developed and has rich functions. It supports model inner and outer diameter compensation, flat graphics conversion to 3D models, and intelligent model segmentation.

FlashPrint also has a basic mode and an expert mode for beginners and professional players. Choose, the software supports Chinese and multiple languages. The final slice generates a GX format file, and the model can be previewed on the printer’s screen.

- Features: FlashPrint has a wealth of practical functions, such as flat image conversion to 3D data, internal and external diameter compensation, etc., and FlashCloud and Happy 3D form a cloud printing management and beginner-designed Flashforging software three swordsmen.

- Insufficient: The cloud printing function is not integrated in FlashPrint, it needs to call the FlashCloud software.

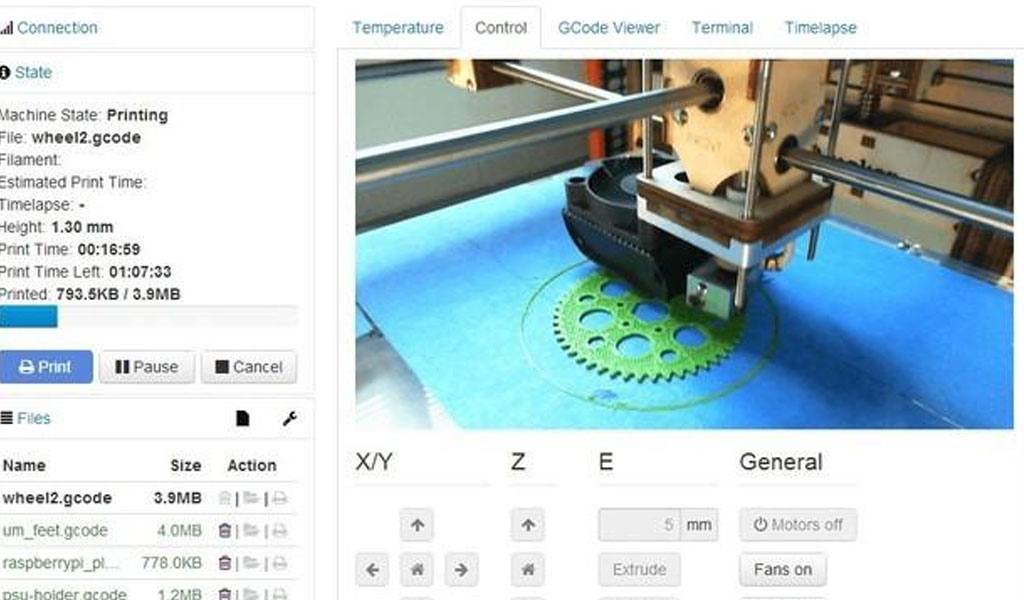

19.OctoPrint

OctoPrint is a lightweight software used to manage users’ 3D printers, allowing users to control and monitor the status of printers through web browsers and mobile devices. OctoPrint can be installed on a Raspberry Pi system, and the user can freely extend it, for example with a webcam and plug-ins.

3D printing jobs can be loaded onto the printer. Among OctoPrint’s many powerful features is an integrated 3D slicer software based on the trusted CuraEngine, meaning users don’t need to slice the file on a computer, just send it through the STL model and the printer will do the rest.

- Features: Open source and free, supports slicing directly in the Raspberry Pi system of the printer.

- Insufficient: not found yet

- OctoPrint download address: http://octoprint.org/

Solving Challenges By Working With An Experienced 3D Printing Partner

If you aren’t quite sure how to incorporate 3D Printing into your business, can’t figure out how to design for 3D printing, or aren’t ready for the investments and technical challenges that come with having 3D printers of your own, it’s best to work with a manufacturing partner. An experienced 3D printing partner can help you overcome many of the top challenges associated with 3D Printing, including upfront equipment costs, inconsistent results, and a lack of 3D printing knowledge. Working with a partner can also give you access to more additive materials and a more comprehensive range of post-processing options.

When you work with Be-Cu.com, we can provide insight into the design and material selection processes for 3D Printing technologies, and even identify cost-saving opportunities to help you maximize your savings and profits. How can you get started? Simply upload your part files or contact us to speak with an 3D Printing expert today.

Check out our resource center to learn more about 3D Printing, including 3D printing layer height, how 3D Printing can help solve supply chain woes, and more.