The evolution of mechanical equipment control technology has been a transformative journey that has shaped various industries and propelled the advancement of automation and efficiency. From the early mechanical linkages to the modern digital control systems, this article traces the key milestones and innovations in mechanical equipment control technology. The progression of control mechanisms, from simple levers to sophisticated autonomous systems, showcases the relentless pursuit of human ingenuity and engineering prowess. This article delves into the historical developments and the impact they have had on industrial processes, setting the stage for a future driven by smart manufacturing and automation.

Early Foundations of Mechanical Control

The Origins of Mechanical Control

The history of mechanical control technology dates back to ancient civilizations, where basic mechanisms like levers and pulleys were used to perform manual tasks. Early innovations laid the foundation for understanding mechanical systems and their behavior.

The Rise of Steam Engines and Governors

The advent of steam engines in the 18th century marked a significant milestone in mechanical control. James Watt’s steam engine featured the centrifugal governor, a critical device that regulated the engine’s speed and ensured stable operation. This innovation not only improved engine efficiency but also became a fundamental concept in control theory.

Early Pioneers of Control Engineering

James Clerk Maxwell and Control Theory

In the 19th century, James Clerk Maxwell’s work in control theory provided valuable insights into system stability and behavior. His contributions to the understanding of mechanical systems paved the way for future advancements in control engineering.

Norbert Wiener and Cybernetics

The 20th century saw the emergence of cybernetics, a field of study that focuses on systems, communication, and feedback. Norbert Wiener’s pioneering work in cybernetics laid the groundwork for feedback control systems and the understanding of self-regulating mechanisms.

The Age of Analog Control Systems

Hydraulic and Pneumatic Control Systems

The early 20th century witnessed the rise of hydraulic and pneumatic control systems, which utilized fluid power to control mechanical processes. These analog systems played a vital role in various industrial applications, including manufacturing, aerospace, and automotive industries.

Electrical Control Circuits

Electrical control circuits became prevalent during this period, enabling the automation of industrial processes. Relay logic, timers, and switches were integrated to control machines and enhance productivity.

The Digital Revolution in Control Technology

Introduction to Digital Control Systems

The digital revolution in control technology began in the mid-20th century with the transition from analog to digital systems. Digital control brought enhanced precision, repeatability, and the ability to program complex functions.

Programmable Logic Controllers (PLCs)

PLCs revolutionized industrial automation, providing a flexible and versatile control solution for various applications. They were widely adopted in manufacturing, process control, and automation due to their reliability and ease of programming.

The Emergence of Computer Numerical Control (CNC)

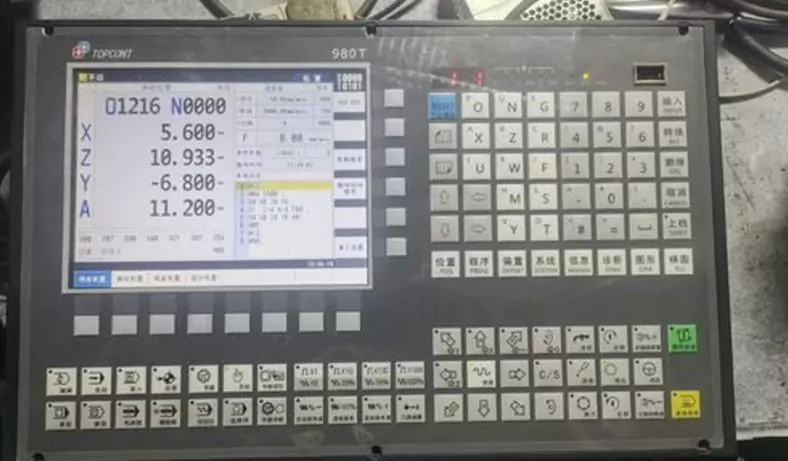

The Rise of CNC Machines

Computer Numerical Control (CNC) machines marked a paradigm shift in the manufacturing industry. CNC technology allowed for the automation of machine tools, improving accuracy and reducing manual intervention in machining processes.

CNC Programming Languages

The development of CNC programming languages, such as G-code, ISO 6983, and ISO 14649, enabled precise control over machine tool movements. CNC machines have become the backbone of modern manufacturing, enhancing productivity and quality.

Robotics and Automation

The Introduction of Industrial Robots

Industrial robots made their debut in manufacturing in the 1960s. These programmable machines brought unparalleled precision, consistency, and speed to repetitive tasks, revolutionizing various industries.

Autonomous Systems and Smart Factories

The integration of robotics and digital control led to the concept of smart factories. Autonomous systems, interconnected through the Internet of Things (IoT), enable real-time data exchange and adaptive manufacturing processes.

Challenges and Future Prospects

Challenges in Cybersecurity

As the complexity of interconnected systems increases, the risk of cyber threats rises. Ensuring robust cybersecurity measures becomes crucial to safeguard critical infrastructure and data.

Advancements in AI and Machine Learning

The future of mechanical equipment control technology lies in the integration of Artificial Intelligence (AI) and Machine Learning. AI-driven control systems offer predictive maintenance, optimized performance, and enhanced decision-making capabilities.

The development of mechanical equipment control technology has been an evolutionary journey that has reshaped industries and redefined manufacturing processes. From humble beginnings with simple levers and pulleys to the sophisticated, autonomous systems of today, control technology has come a long way. The progress in control theory, the transition to digital systems, and the integration of automation have paved the way for a future driven by smart manufacturing and Industry 4.0. The continuous pursuit of innovation in mechanical equipment control technology promises a world of boundless possibilities, propelling us into an era of unprecedented efficiency and automation.

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!