The Define Of 3D Printing Filament

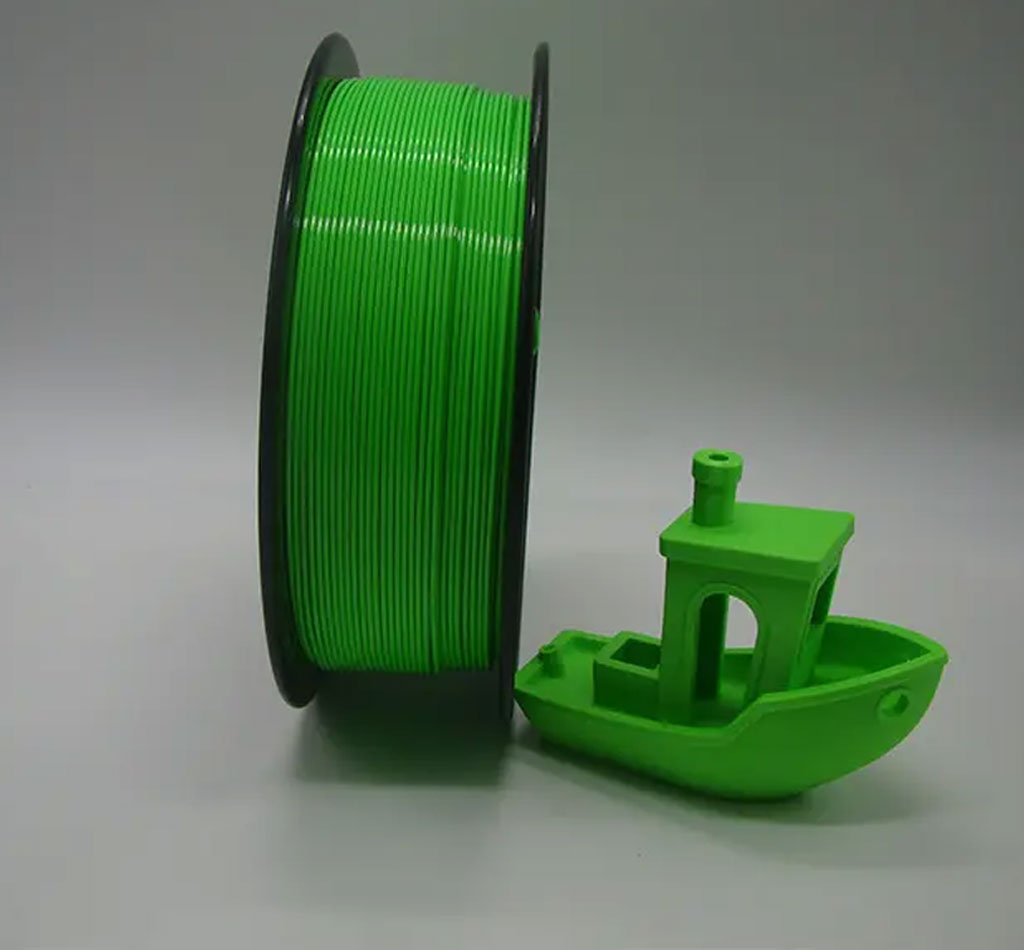

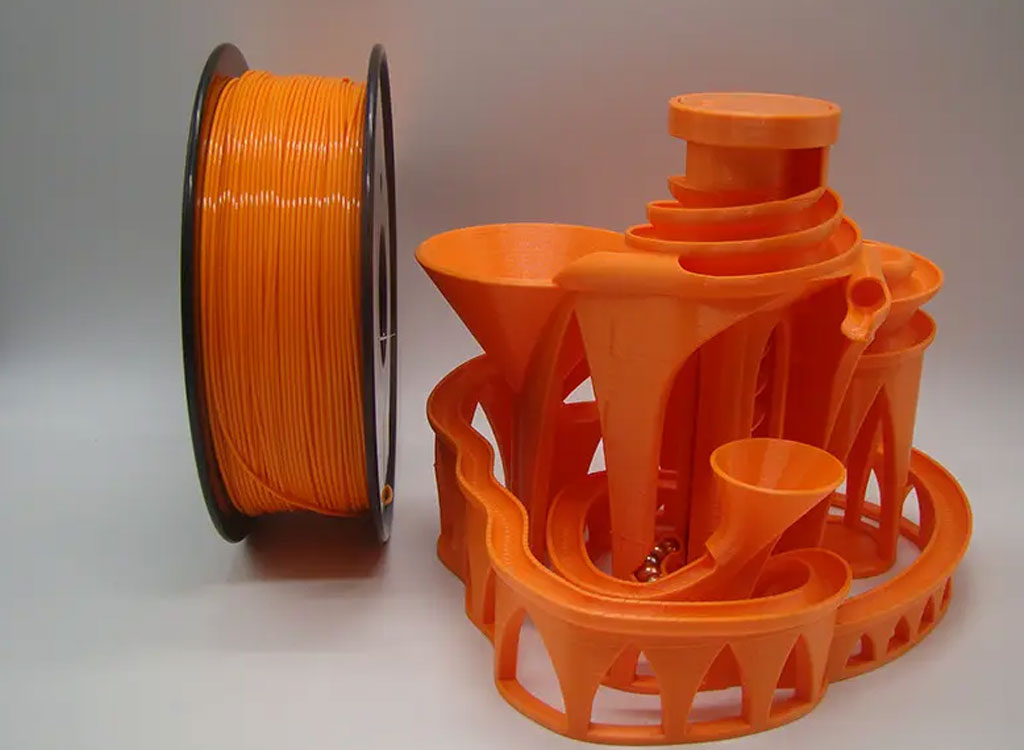

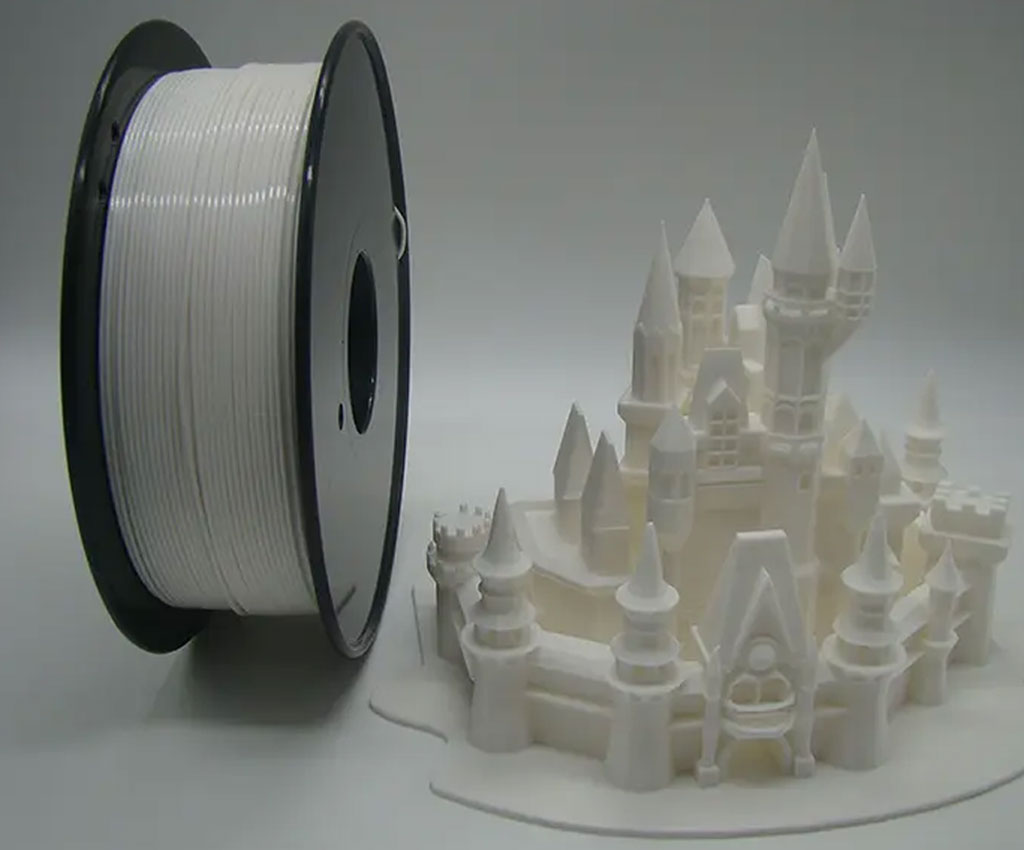

3D printing filament is the material used as the raw feedstock in 3D printers to create three-dimensional objects. It is a long, thin strand or thread that is heated and melted by the 3D printer’s extruder and then deposited layer by layer to build up the final object.Filament is typically supplied in the form of a spool or a coil, and it comes in various materials, colors, and diameters. The choice of filament material depends on the desired properties of the printed object, such as strength, flexibility, heat resistance, transparency, or biodegradability.

3D Printing Filament Inventor,History And Development

The history of 3D printing filament is closely tied to the evolution and advancements in 3D Printing technology. Filament, as a consumable material, plays a crucial role in the 3D printing process, providing the raw material for creating three-dimensional objects layer by layer. Here’s a brief overview of the history of 3D printing filament:

Early Days and Fused Deposition Modeling (FDM):

In the late 1980s, Scott Crump, the founder of Stratasys, developed Fused Deposition Modeling (FDM), the most popular and widely used 3D printing technology today.

The first 3D printers using FDM technology primarily utilized ABS (Acrylonitrile Butadiene Styrene) filament, which was a common plastic material known for its strength and durability.

Expansion of Materials:

As 3D printing technology advanced and became more accessible, the range of materials used as filaments expanded.

PLA (Polylactic Acid) emerged as an alternative to ABS due to its biodegradability, ease of use, and lower melting temperature.Other materials such as nylon, PETG, TPU, and composite filaments with added additives like wood, metal, or carbon fiber were introduced, offering a broader range of functional and aesthetic possibilities.

Specialized Filaments:

With the growing popularity of 3D printing, filament manufacturers started producing specialized filaments tailored to specific applications.

Filaments with improved mechanical properties, such as higher strength or heat resistance, were developed to meet the demands of industries like aerospace, automotive, and engineering.

Filaments with unique properties, such as conductive filaments for creating circuits or flexible filaments for producing rubber-like objects, also entered the market.

Experimentation and Innovation:

3D printing enthusiasts and researchers have constantly explored new materials and filament formulations, pushing the boundaries of what can be printed.

Recycled filaments made from recycled plastics or other waste materials have gained attention as a more sustainable option.

Bio-based and eco-friendly filaments derived from renewable resources, such as corn starch or algae, have been developed as alternatives to traditional plastics.

The development of 3D printing filament is an ongoing process, with continuous improvements in filament quality, consistency, and performance.

Manufacturers are investing in research and development to create filaments with better printability, reduced warping, improved layer adhesion, and enhanced surface finish.

Today, 3D printing filament is available in a wide range of materials, colors, and properties to suit various applications and meet the evolving needs of industries and individuals. The history of 3D printing filament reflects the growth of 3D printing technology as a whole, as both have advanced in parallel to expand the possibilities of additive manufacturing.

The Types of 3D Printing Filament

3D printing filament is a crucial component in the 3D printing process and comes in various types, each offering unique properties and characteristics.

You need to choose the type of filament to use for the 3D printer, among a variety of filaments with different colors and characteristics, how to choose the right 3D printing filament? Let’s learn about the types of filaments used in 3D printing.

PLA (Polylactic Acid)

ABS (Acrylonitrile Butadiene Styrene)

PETG (Polyethylene Terephthalate Glycol)

TPU (Thermoplastic Polyurethane)

Nylon

PVA (Polyvinyl Alcohol)

Wood-filled Filaments

Metal-filled Filaments

HIPS (High Impact Polystyrene)

Carbon Fiber

Different Sizes Of 3D Printing Filament

3D printing filament is available in different sizes or diameters, which are standardized across the industry. The two most common filament sizes used in 3D printing are 1.75mm and 2.85mm (or 3.00mm). The filament diameter refers to the thickness of the filament strand that is fed into the 3D printer’s extruder for melting and deposition.

- 1.75mm Filament: This is the most widely used filament diameter in consumer-grade 3D printers. It offers a good balance between compatibility and flexibility. Many popular 3D printers are designed to specifically handle 1.75mm filament. It is commonly available in various materials and colors.

- 2.85mm (or 3.00mm) Filament: This filament size was more prevalent in the early days of 3D printing and is still used by some printers, particularly in industrial or professional settings. Some manufacturers refer to this size as 3.00mm, but it is essentially the same as 2.85mm. 2.85mm filament is known for its high flow rate and is often used in large-format or high-speed 3D printers.

It’s important to note that filament size compatibility is specific to each 3D printer. When purchasing filament, it is essential to ensure that the filament diameter matches the requirements of your particular printer. Using the wrong filament size can result in feeding issues, extrusion problems, or clogs in the printer’s hot end.

Additionally, filament spools come in various weights, commonly ranging from 0.5kg to 1kg or even larger. The weight of the spool indicates the amount of filament on it and determines how much printing can be done before the filament needs to be replaced or reloaded.

1.75mm and 2.85mm (3.00mm) are the most prevalent filament sizes in the 3D printing industry, with 1.75mm being the most widely used for consumer-grade printers. Always check the specifications and requirements of your 3D printer to ensure you select the appropriate filament size for optimal printing performance.

How To Mix 3D Filament Colors

When attempting to mix filament colors, it’s essential to ensure that the filaments are compatible in terms of material properties and printing temperatures. Some filaments may have different melting points or behaviors, which can affect the quality of the color mixing or the overall print.

Overall, mixing filament colors in 3D printing can result in visually appealing and creative prints. However, it is important to consider the capabilities of your specific 3D printer and experiment with different techniques and settings to achieve the desired color effects.

To mix 3D filament colors and create blended or multi-color prints, there are a few different methods you can try. The specific method you choose may depend on your 3D printer, filament types, and desired color effect. Here are three common approaches to mixing filament colors:

Filament Blending

- Cut or trim small segments of two or more filament colors that you want to blend.

- Load the cut segments into a filament splicer or filament joiner device, which will combine the filaments into a single strand.

- Ensure that the blended filament is properly aligned and fed into the extruder.

- Start the printing process as usual, and the extruder will melt and blend the different colors, resulting in a mixed color effect in the printed object.

Gradient Transition

- Load one filament color into the printer and start printing.

- While the first color is being printed, pause the print process at a specific layer height or time interval.

- Manually swap the filament with a different color.

- Resume the printing process, and the new color will gradually blend with the previous color, creating a gradient transition between the two colors.

Dual Extrusion

- Use a 3D printer that supports dual extrusion, which has multiple extruders or hot ends.

- Load each extruder with a different filament color.

- Prepare or design your 3D model with color assignments for different parts or layers.

- Configure the slicing software to assign the appropriate extruder to each color section.

- Start the print process, and the printer will automatically switch between the extruders as it progresses through the layers, resulting in a multi-color print.

Before attempting any of these methods, it’s crucial to ensure that the filaments you plan to mix are compatible in terms of material properties and printing temperatures. Additionally, calibrating the printer settings and experimenting with different techniques may be necessary to achieve the desired color mixing effect.

Remember to follow the specific instructions provided by your 3D printer manufacturer and refer to any documentation or guides for filament blending or dual extrusion capabilities.

Keep in mind that the success of color mixing can vary depending on the filament types, printer settings, and the specific 3D printing technology you are using. It may require some trial and error to achieve the desired color results.

What Filament Can You 3D Print the Fastest With?

The filament that can be 3D printed the fastest depends on various factors, including the specific printer model, printing settings, and the desired print quality. However, there are certain filament types that generally allow for faster printing speeds due to their properties. Here are a few filaments that are often known for their faster print speeds:

- PLA (Polylactic Acid): PLA is a popular filament choice for 3D printing, known for its ease of use and wide availability. It typically allows for faster print speeds compared to other filaments. PLA has a lower melting temperature and good flow characteristics, which enable faster extrusion rates. However, the actual printing speed will depend on the specific PLA formulation, the printer’s capabilities, and the complexity of the print.

- PETG (Polyethylene Terephthalate Glycol): PETG is another filament that is known for its faster print speeds. It has similar properties to PLA but offers improved strength and durability. PETG has good layer adhesion and can handle higher extrusion rates without sacrificing print quality. It is also less prone to warping compared to PLA, making it suitable for larger prints.

- TPU (Thermoplastic Polyurethane): TPU is a flexible filament that can be printed at faster speeds due to its elasticity and ability to stretch. The unique properties of TPU allow it to handle higher print speeds while maintaining good print quality. However, it’s important to note that TPU may require some additional printer setup and tuning to optimize the printing process.

It’s crucial to consider the trade-off between print speed and print quality. Increasing the print speed too much may lead to decreased accuracy, layer adhesion issues, or other printing problems. It’s recommended to experiment with different speeds and optimize the print settings for each filament type to achieve the right balance between speed and quality.

Additionally, it’s worth noting that advancements in printer technology and slicer software can also contribute to faster print speeds. High-performance 3D printers with advanced extruders, faster movement systems, and improved heat management can achieve faster print times with various filament types.

Remember to always refer to the manufacturer’s recommendations, guidelines, and your specific printer’s capabilities when determining the appropriate printing speed for a particular filament.