The term “3D printing” covers a wide range of processes and technologies that offer a broad range of capabilities for producing parts and products from different materials. In recent years, these processes have evolved significantly and can now play a key role in many applications.3D printing is usually achieved using digital technology material printers.

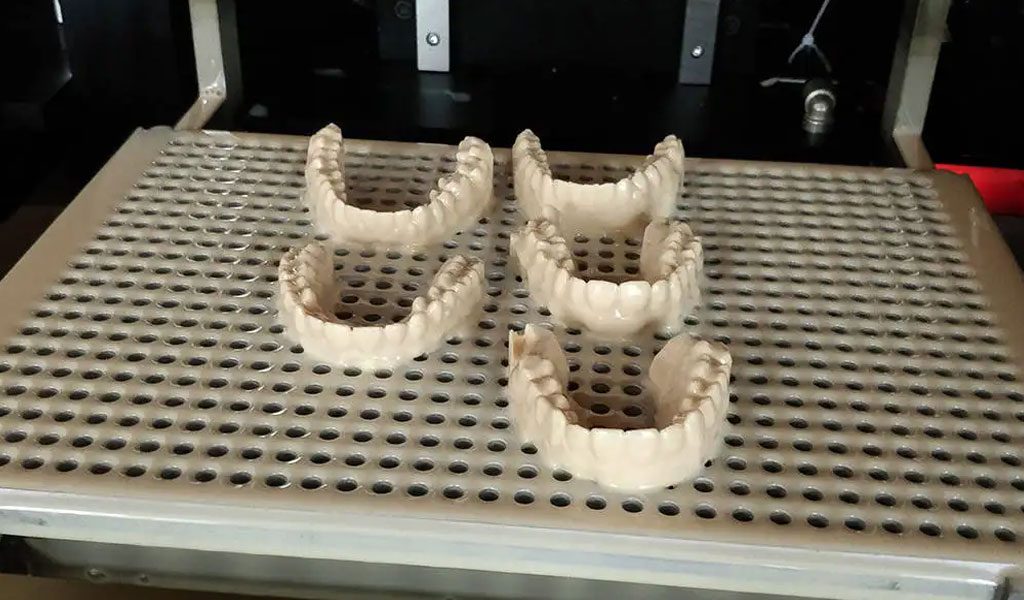

It is often used to make models in areas such as mold making and industrial design, and then gradually used for the direct manufacturing of some products, and there are already parts printed using this technology.The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms, and other fields.

This overview article aims to explain the different types and processes of 3D printing, how they work, and their uses and advantages in the current market. Let’s start with a very basic question.

What Is 3D Printing?- The Define Of 3D Printing

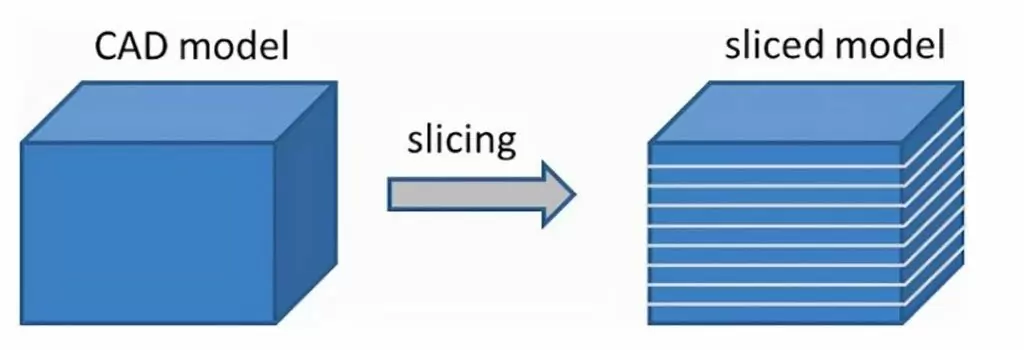

What Is 3D printing?, also known as additive manufacturing or 3DP, is a process for making physical objects from a 3D digital or CAD model. It involves various computer-controlled techniques in which materials are joined or solidified to build the actual object.

Typically, materials (such as powder particles or liquid molecules fused together) are added layer by layer on a millimeter scale. This is why 3D printing is also known as an additive manufacturing process.

In the 1990s, 3D printing techniques were known as rapid prototyping. They were only suitable for making aesthetic or functional prototypes. We’ve come a long way since then.

Today’s 3D printing technologies are advanced enough to create complex structures and geometries that would otherwise be impossible to build manually.

The accuracy, material range, and repeatability of 3D printing have increased to the point where we can build almost anything-from simple prototypes to complex end products such as environmentally friendly buildings, aircraft parts, medical devices, and even artificial organs-human cells using multiple layers of materials.

How It Works And 3D PrintingExamples

All 3D printing technologies are based on the same principle: a 3D printer takes a digital model (as input) and turns it into a physical 3D object by adding material layer by layer.

It is very different from traditional manufacturing processes such as injection molding and CNC machining, which use various cutting tools to build the desired structure from a solid block. However, 3D printing does not require cutting tools: objects are manufactured directly on the platform on which they are built.

Depending on the type of printer and the size of the object, printing can take several hours to complete. Printed objects often require post-processing (such as sanding, varnishing, painting or other types of conventional finishing) to achieve the best surface finish, which requires additional time and labor.

Different types of 3D printers use different technologies and handle different materials in different ways. Perhaps the most fundamental limitation of 3D printing in terms of materials and applications is that there is no one-size-fits-all solution.

The Types Of 3D Printing And Processes

According to the ISO/ASTM 52900 standard, all 3D printing processes can be divided into seven groups. Each method has advantages and disadvantages, usually related to cost, speed, material properties and geometric limitations.

1.Reduction Photopolymerization

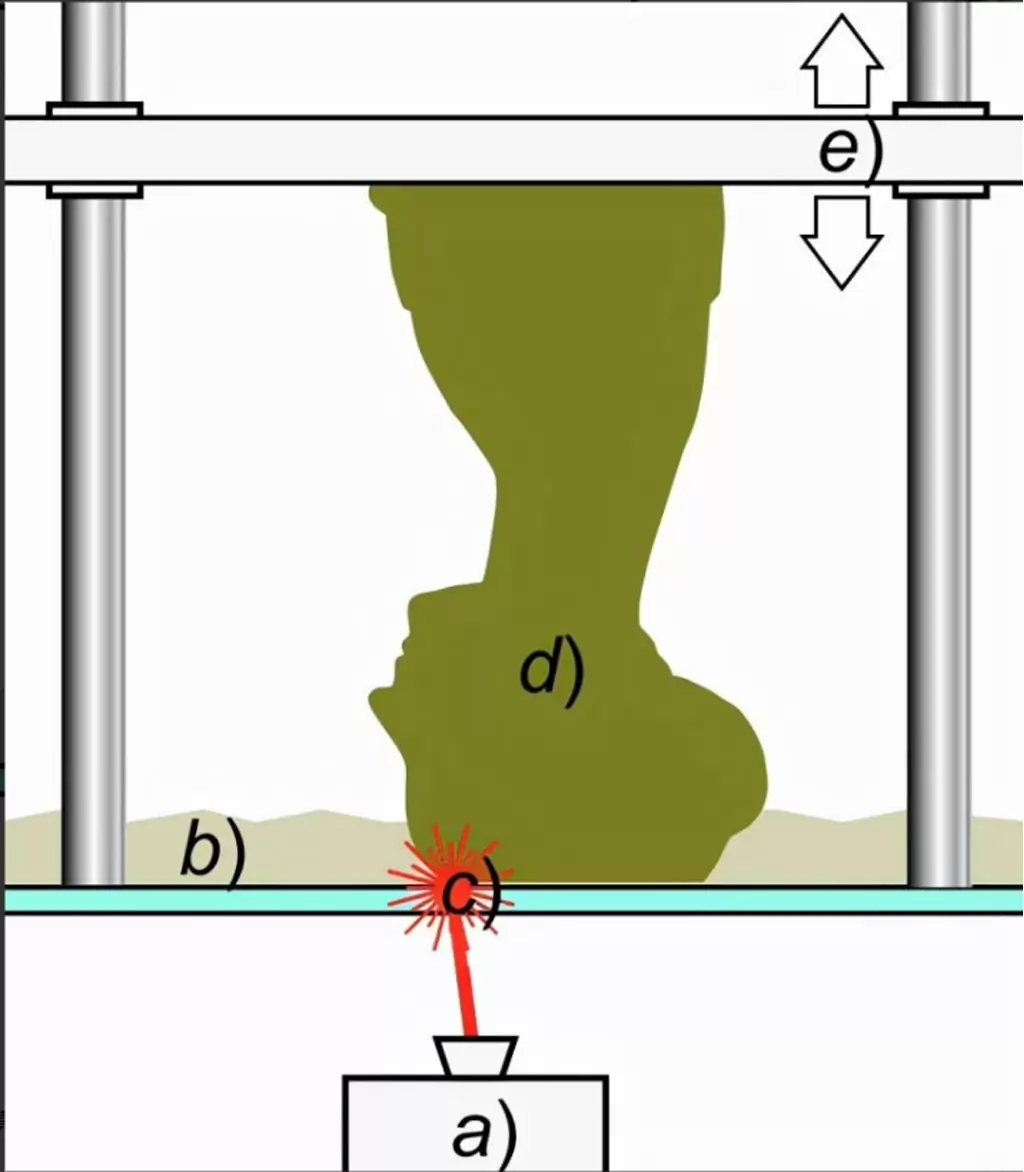

Illustration: The laser (a) selectively illuminates the transparent bottom (c) of the tank (b) filled with liquid photopolymerization resin. The lifting platform (e) gradually drags the cured resin (d) upwards.Vat photopolymerization-based 3D printers have a container with a photopolymer resin that is hardened with a UV light source to create objects. The three most common forms of reductive polymerization are:

- 1a) Stereolithography (SLA): Invented in 1984, SLA uses a UV laser to cross-link chemical monomers and oligomers to form a polymer that forms a three-dimensional body. While this process is fast and can build almost any structure, it can be expensive.

- 1b) Digital Light Processing (DLP): It uses a conventional light source, such as an arc lamp (rather than a laser). Each layer of the object is projected onto a bucket of liquid resin, which then cures layer by layer as the lifting platform moves up and down.

- 1c) Continuous Liquid Interface Production (CLIP): It is similar to stereolithography, but is continuous and can be done at speeds up to 100 times faster. CLIP can produce rubber-like and flexible objects with smooth sides that cannot be created by other techniques.

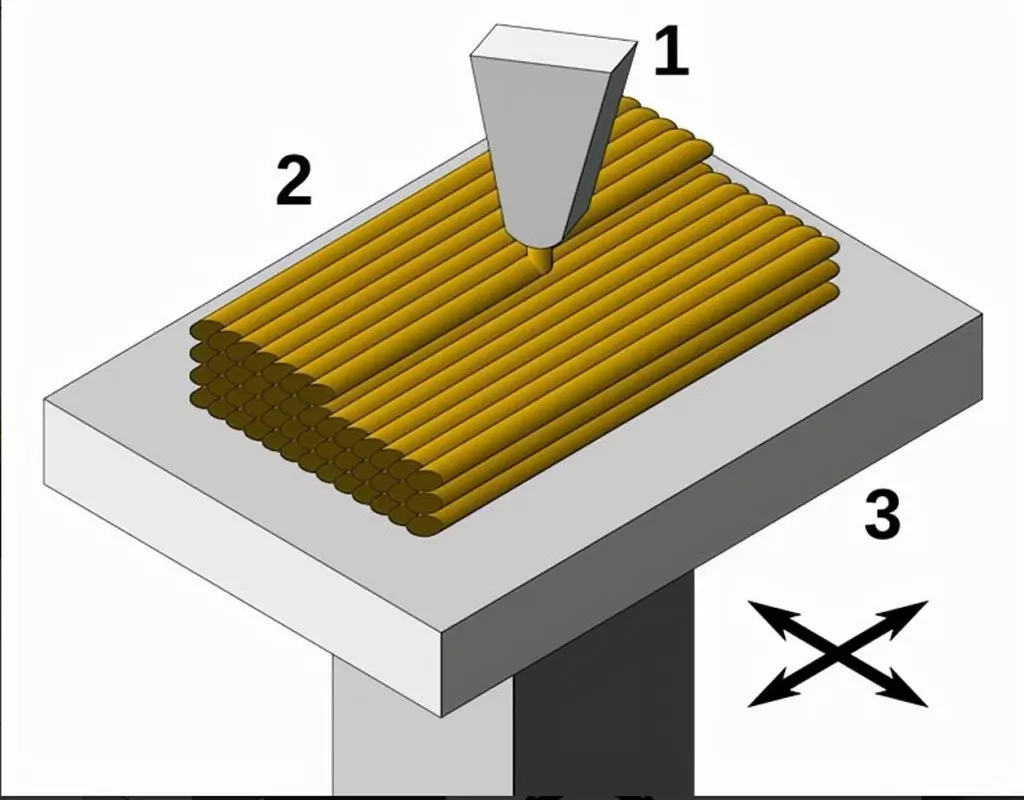

2.Material Extrusion

In this process, a thin filament of solid thermoplastic material is pushed through a heated nozzle that melts the material and deposits it on the build platform along a predetermined path.

This material eventually cools and solidifies, forming a three-dimensional object(as mjf 3d printing). The most common techniques used in this process are shown below.

- 2a) Fused Deposition Molding (FDM): It uses continuous filaments of thermoplastic materials, such as nylon, TPU or PLA.

- 2b) Robocasting: It involves extruding a paste-like material from a small nozzle while the nozzle moves across the build platform. This process differs from FDM in that it does not rely on drying or curing of the material to retain its shape after extrusion

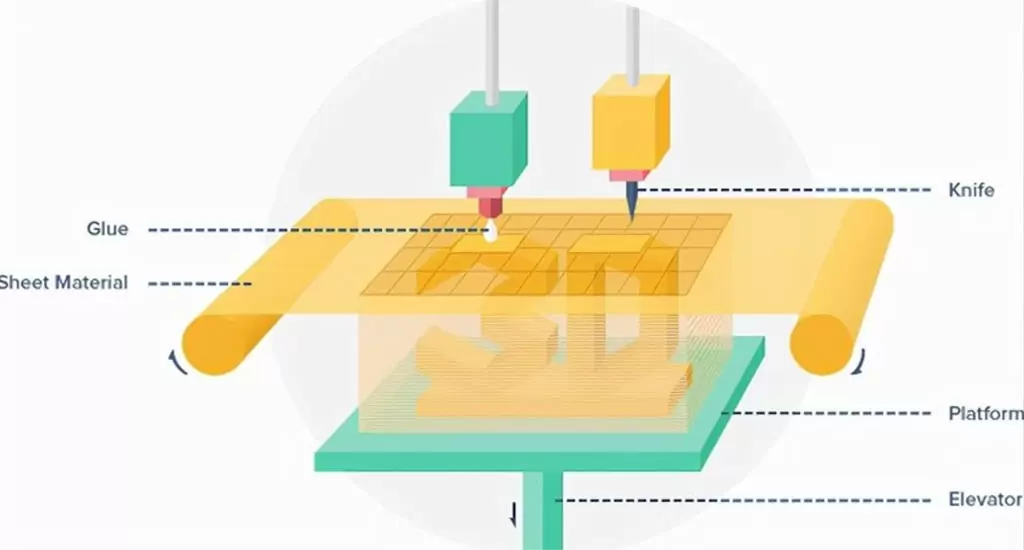

3.Sheet Lamination

Some printers use paper and plastic as build materials to reduce printing costs. In this technique, multiple layers of adhesive plastic, paper or metal laminates are sequentially joined together and cut to shape using a laser cutter or knife.

The layer resolution can be defined by the material raw material. It usually ranges from one to several sheets of copy paper. This process can be used to make large parts, but the dimensional accuracy of the final product will be much lower than that of stereolithography.

4.Directed Energy Deposition

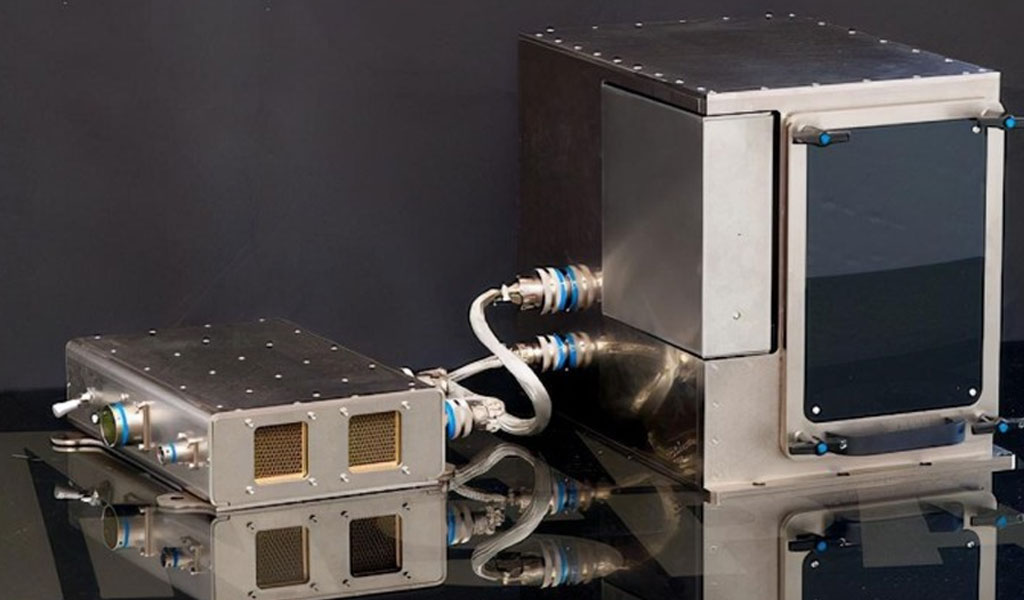

Directional energy deposition is commonly used in the high-tech metal industry and for additive manufacturing applications. The printing device consists of a nozzle fixed to a multi-axis robot arm. The nozzles deposit metal powder(metal 3d printing powder) on a build platform, which is then melted by a laser, plasma or electron beam to form a solid object.

This type of 3D printing supports a variety of metals, functional gradient materials and composites, including aluminum, stainless steel and titanium. Not only can it build entirely new metal parts, but it can also attach materials to existing parts, enabling hybrid manufacturing applications.

5.Sheet Lamination

- Material jetting operates in a similar manner to inkjet paper printers. In this process, light-sensitive materials are coated into droplets through a small-diameter nozzle and then hardened with UV light to build a part layer by layer.

- The material used in this technology is a thermosetting photopolymer (acrylic resin). Multiple material printing and a variety of materials (including rubber-like and transparent materials) are also available.

- Because material jetting 3D printing allows the construction of high dimensional accuracy parts with a smooth surface finish, it is an attractive option for the manufacture of visual prototypes and commercial tools.

6.Adhesive Jetting

- Adhesive Jet uses two materials: a powder substrate and a liquid adhesive. The powder is evenly distributed in the build chamber and the binder is applied through a nozzle to “glue” the powder particles together to build the desired object.

- Waxes or thermoset polymers are typically mixed with the bonding powder to increase its strength. After 3D printing is complete, the remaining powder is collected and used to print another structure.

- This technique is also known as infusion 3D printing because it is very similar to a process similar to inkjet. It is primarily used to print elastomeric parts, drapes and color prototypes.

7.Powder Bed Fusion

Powder bed fusion is a subset of additive manufacturing in which a material in powder form is solidified using a heat source (such as a thermal print head or laser) to build physical objects. The five most common forms of this technology are:

- 7a) Selective Laser Sintering (SLS): It uses a laser as a power source to sinter powdered materials such as polyamide or nylon. The term sintering here refers to the process of compacting and forming a solid block of material by applying pressure or heat without melting it to the point of liquefaction.

- 7b) Selective Laser Melting (SLM): Unlike SLS, this technique is designed to completely melt and fuse metal powders together. It creates a completely dense material (layer by layer) with mechanical properties similar to those of conventionally manufactured metals. This is one of the rapidly developing processes being implemented in industry and research.

- 7c) Electron Beam Melting (EBM): In this process, the raw material (wire or metal powder) is placed in a vacuum and melted together using an electron beam. Although EBM can only be used with conductive materials, it offers superior build speed due to its higher energy density.

- 7d) Selective Thermal Sintering (SHS): It uses a thermal print head to heat up the powdered thermoplastic layer. Once a layer is completed, the powder bed moves down and a new layer of material is added, i.e. it is then sintered to form the next cross-section of the model. This technique is best suited for manufacturing inexpensive prototypes and parts for functional testing.

- 7e) Direct Metal Laser Sintering (DMLS): It is similar to SLS, but uses metal power instead. The remaining energy becomes the support structure for the object and can be reused for the next 3D printing. DMLS parts are made primarily from powdered materials such as titanium, stainless steel, aluminum and several specialty alloys. It is the ideal process for custom medical parts, oil and gas components, and robust functional prototypes.

The Application Of 3D Printing

3D printing has grown considerably in the last decade. Because it can be used to rapidly manufacture complex designs at a lower cost, it has become a must-have tool for a variety of industries, from commercial manufacturing and medicine to architecture and custom design.

Many additive manufacturing technologies can be used to make food products. Modern 3D printers come with pre-loaded on-board recipes and also allow users to create their food remotely on their computers and smartphones. 3D printed food can be customized in terms of texture, color, shape, flavor and nutrition.

The technology has also proven effective in pharmaceutical formulations. The first formulations manufactured with 3D printing were produced in 2015. That same year, the FDA approved the first 3D-printed tablet.

In 2014, SpaceX delivered the first zero-gravity 3D printer to the International Space Station. Now, astronauts use it to print useful tools, such as socket wrenches.

In fact, many planned assembly projects on planets or asteroids will be initiated in some way using materials available in nearby regions. 3D printing is one of the main steps in this bootstrap.

Today, technology companies are combining additive manufacturing with cloud computing to enable decentralized and geographically independent distributed production. Some companies offer online 3D printing services to private and commercial customers (through websites, such as Be-cu.com).

The Future Of 3D Printing

In 2014, SpaceX delivered the first zero-gravity 3D printer to the International Space Station. Now, astronauts use it to print useful tools, such as socket wrenches.

In fact, many planned assembly projects on planets or asteroids will be initiated in some way using materials available in nearby regions. 3D printing is one of the main steps in this bootstrap.

Today, technology companies are combining additive manufacturing with cloud computing to enable decentralized and geographically independent distributed production. Some companies offer online 3D printing services to private and commercial customers (through websites, such as Be-cu.com).

The big dream for 3D printing is “a factory for everyone”. This may sound strange, but there is no denying the appeal of having a machine that can instantly produce infinitely customizable things.

Just as computers and smartphones have empowered billions of people, 3D printers could do the same for manufacturing.

According to GrandViewResearch, the global 3D printing market is valued at $11.58 billion in 2019 and is expected to exceed $33 billion by 2027 (growing 14% annually).

Factors expected to drive market growth include aggressive R&D and growing demand for prototype applications from various verticals, particularly automotive, aerospace, defense, and healthcare.