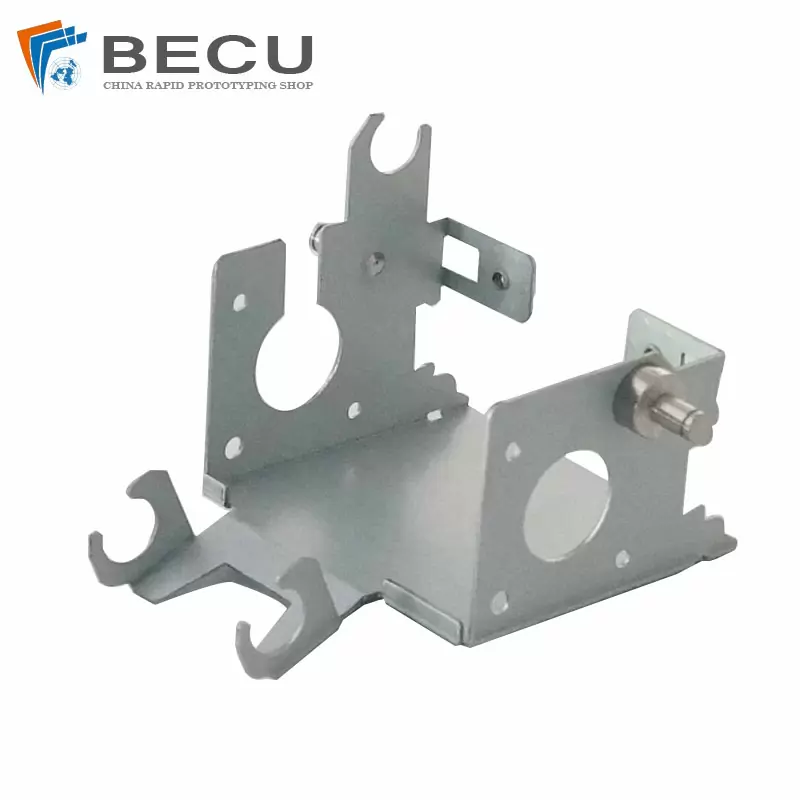

Control Module

- Material: SECC Steel

- Process: Metal Stamping And Mold Making

- Stamping Size: Custom Size

- Stamping Type: Metal Forming

- Stamping Mold: Compound Mold

- Tolerance: Custom

- Fine Blanking Method: Multi-Station

- Surface Treatment: Custom

High-Quality Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module

The hardware stamping part of the fixing plate shown is a stable, strong and durable precision part designed by Be-cu.com for the transmission module of the intelligent security patrol robot. This article mainly shows the parameters, process and some common problems of this part from various aspects. Be-cu.com provides R&D, production and phased test services for precision structural parts and modules of smart terminal products, and cooperates with customers to develop product markets.This part has the following features:

- Timely delivery, the company has a production team of 700 people to deal with production, and PMC engineers coordinate the production plan;

- Good inlay performance, with holes, tapping and other treatments carried out in many places, which is convenient for product assembly and fitting;

- It is convenient to update and iterate, and the products are mass-customized. When the function is updated, the cost of batch update of structural parts can be effectively reduced;

- High-quality service, the company arranges engineers to provide “1V1” service to ensure that products can get stable quality assurance in the stages of design, production and after-sales;

- The structure is stable, the part has good tensile properties, the surface treatment layer also has special anti-corrosion properties, and the hardness is moderate;

Note: More detailed photos of the products at the bottom of the page are used to show the product features of the metal stamping parts of the fixed plate.

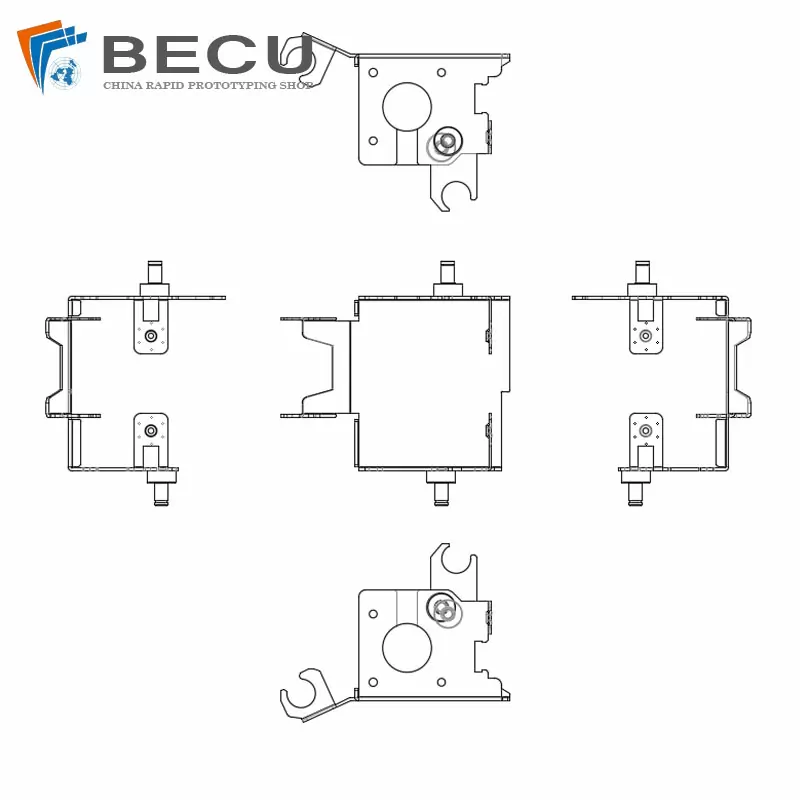

The Parameters Of Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module

| Product Size | 103.8*71*79mm | Expand Size | 196.4*116.5*1.2mm |

|---|---|---|---|

| Product Material | SECC | Material Thickness | 1.2mm |

| Product Weight | 130.8g | Mold Ttype | Single die & compound die, 5 sets in total |

| Surface Treatment | none | Processing Difficulty | Simple |

| Size Tolerance | ±0.1mm | Angle Tolerance | ±0.3° |

The Production Process Of Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module

| Serial Number | Process | Punch Tonnage | Process Description And Precautions |

|---|---|---|---|

| 1 | Composite Blanking | 200 tons | The shape and prototype hole of the product are punched out at one time, and at the same time, the size requirements of the product and the burr height requirements of the product can be guaranteed; |

| 2 | Cloak The Front, Turn The Pig’s Mouth | 200 tons | There are 2 processes in this trip, and the prototype is punched out. The structure of the stamping die in this trip is relatively complex and requires high precision; |

| 5 | Teeth | 2-M3 | Tapping is performed on 2 special holes, the size is M3, and the hole size deviation is less than or equal to 0.1mm; |

| 6 | L Song | 200 tons | The stamping process is used to bend the product; |

| 7 | L Song | 200 tons | The angle and size formed by stamping and bending are very precise; |

| 8 | Socket Nail | Auxiliary process | Press riveting, combined with step 5; |

| 9 | U Song | 200 tons | The last stamping process is followed by secondary processing; |

| 10 | Degreasing | Auxiliary process | Plasma cleaning to remove surface oil; |

| 11 | Quality Inspection | Auxiliary process | Comprehensively inspect the dimensional error of the metal stamping parts of the fixed plate , and eliminate the products with surface oil defects in time to avoid entering the next process; |

| 12 | Package | Auxiliary process | Packaging engineers design exclusive packaging solutions to ensure the quality of products in the follow-up operation process and avoid losses; |

Why Choose Our Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module Service?

- Are Cost-Efficient

- Manufacture Parts That Are Precision-Built

- Expert-Level Consultation and Design Assistance

- Provide Free Tool & Die Insert Storage and Maintenance

- Offer Complete In-House Tool & Die Capabilities

- BE-CU And His Core Supplier Sipx has large to small precision stamping presses. Our presses range from 40 to 700 tons, with bed sizes up to 150 inches and speeds up to 400 strokes per minute.

- Specializing in automated precision progressive dies, our feed capability ranges from 0.008 to 0.375 inch thick material with coil widths up to 50 inches and weights to 15,000 pounds.

Advanced Equipment to Create a Diverse Range of Designs,Sizes, and Thicknesses Large or Small Parts Can Be:

- – Pierced

- – Formed

- – Drawn

- – Extruded

- – Marked

- – And More!

Expert-Level Consultation and Design Assistance including:

- Engineering drawing analysis

- Design feasibility reviews

- Functionality assessments

- Confirmation of supply tolerances, cost ratios, and other important project considerations

- Informed recommendations about when to use stamping versus other technologies

Contact Be Cu Now for your Custom Metal Stamping, We are your best online Stamping services choice!

Specifications of Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module

| Raw Material Thickness | 0.040″ to 0.375″ |

| Material | Stainless Steel (304, 305, 316, 430 & 434), Aluminum (3003, 5052, 6061), Cold Rolled Steel (1008, 1010), High Carbon Steel (1035), Nickel and Pre-plated Steel, Galvannealed Steel, Brass (80-20, 80-15, 70-30), Copper, HSLA. |

| Presses Ranging | 40 to 700 tons |

| Stamping Process | Flanging, punching, bending, necking, trimming, deep drawing, cold extrusion, precision blanking, bulging |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Zinc plating,Electroplating,etc |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Common Problems Of Precision Metal Stamping Intelligent Security Patrol Robot Transmission Module

1.How is the product quality of your company (metal stamping parts) guaranteed?

answer: Be-cu.com has cooperated with Japanese, German and other enterprises for many years, constantly improving the quality inspection system and improving the quality requirements, and has achieved a consistent good reputation in product quality, with a product qualification rate of 98% . Mainly from the following aspects:

First, all staff participate in the quality inspection, and at the same time, each process of the product will be inspected by a quality inspection engineer to exclude defective products and enter the next link;

Second, the introduction of advanced monitoring equipment, such as three-dimensional detectors, etc.;

Third, cooperate with customers in time to reduce the cost loss caused by the change of stamping parts;

Fourth, it is not to improve the quality management system and optimize the production process of products;

Be-cu.com has been active in foreign advanced production equipment and training high-end technical talents for many years, laying a solid foundation, aiming to contribute more strength and scientific research and technical support in promoting the upgrading of China’s precision and intelligent manufacturing!

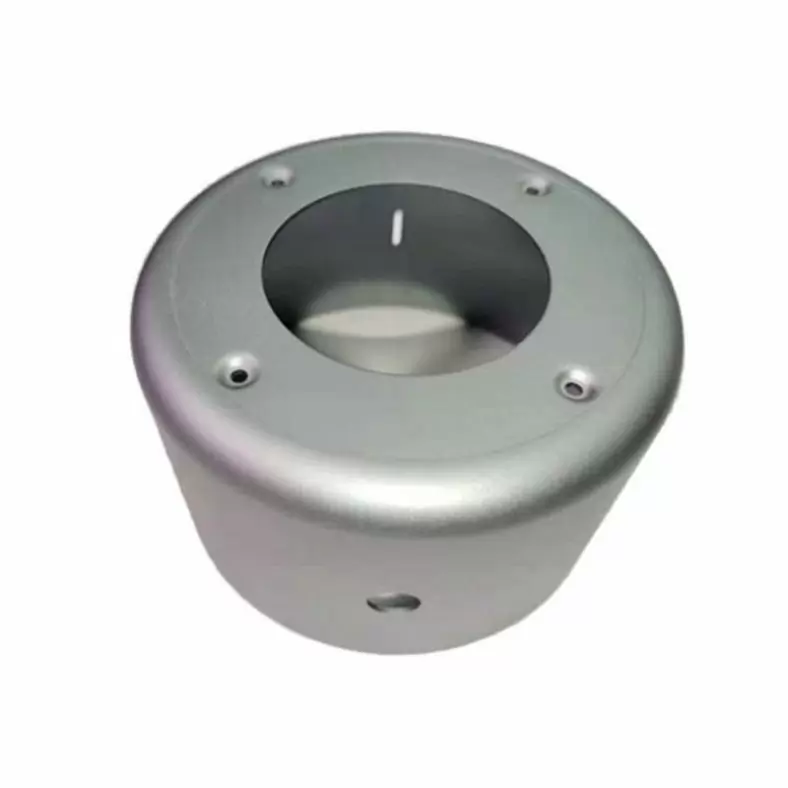

2. In addition to the fixed plate metal stamping parts, can you also customize the complex metal stamping parts of other parts?

A: When the process allows, when the customer puts forward the clear demand for the product, our company can meet the production demand of any part of the metal stamping parts. For example, shell metal stamping parts, bracket metal stamping parts, cover metal stamping parts, etc.

At present, the product items involved in the metal stamping parts of the fixed plate include storage robots, patrol robots, home robots, food delivery robots, etc. If you have any other product requirements, please contact our company, and our company will arrange engineers to conduct 1V1 discussions with you.

The Detail Of BE-CU Metal Stamping Company

BE-CU.COM is a China based manufacturer offering Metal Forming services. Our plant specializes in Stamped Metal parts, post machining services and plating or painting. We press a comprehensive range of standard and complex custom shapes and some very challenging designs. With number of processes under one roof we manufacture all sort of products and offer assembly services.Your part drawings will be reviewed in house by be-cu engineers. The press will be designed around the profile according to the intended use for the metal part. Some design considerations, such as wall thickness, tolerances ant type of the metal may need to be taken into account. Off-tool samples will be provided to you after drawings are approved and tool been made.Our team of assemblers specialize in mechanical and electrical assembly of components. We are experienced with a large variety of assembly from simple one or two part additions to complete complex cabinets and assemblies. Additional services also include but not limited to Powdercoating, Plating, E-Coating, General Engineering and custom packaging.