With the rapid development of electronic information technology, the world’s CNC machine tools have entered the era of mechatronics with digital manufacturing technology as the core, and its representative is CNC machine tools.

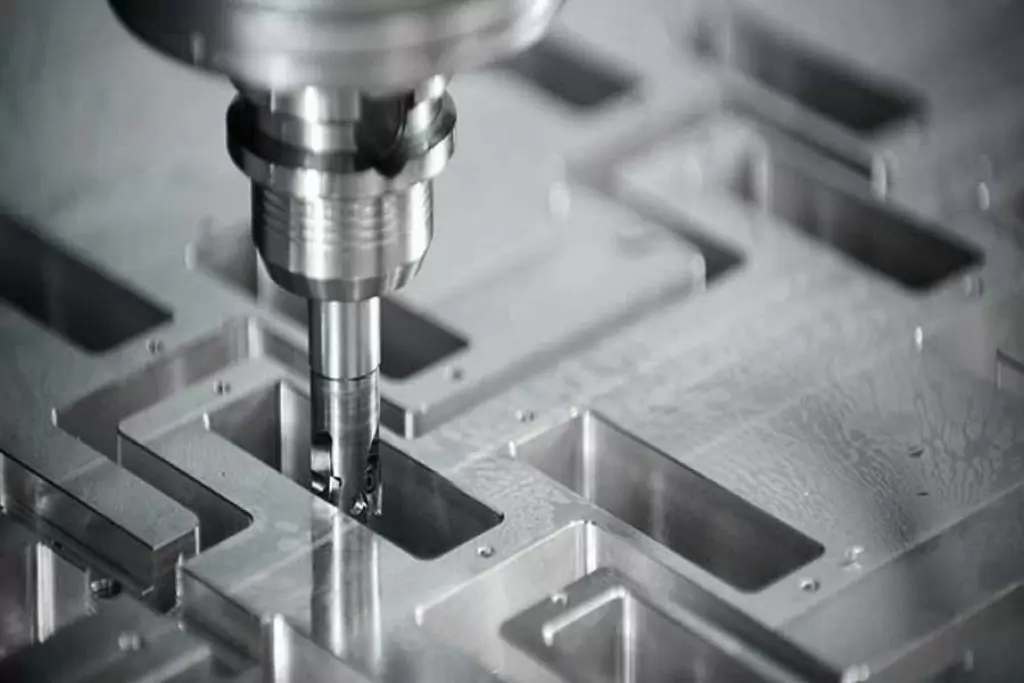

The CNC machine tool adopts digital form for information control, which makes the machine tool machining more flexible, fast, stable and efficient. It is an automated machine tool processed in the modern manufacturing industry.CNC machining has a high degree of automation, good stable machining quality and machining accuracy, so it can perform multi-coordinate linkage and process parts with complex shapes. It is especially suitable for CNC Machining trough parts, curved parts, and parts with many holes and slots.

Cnc Machining Definition

What Is Cnc Machining?It generally refers to the process of custom parts on CNC Machine Tools Or Cnc Machining Center.CNC machining is based on the part model and process requirements to be cnc machined, programmed in ATL and NC language and input into the control computer or CNC entry system of the CNC machine tool to control the relative movement of the workpiece and the special tool, thereby machining high standards The way of qualified parts. The process regulations of CNC machine tool machining and traditional machine tool processing are generally the same, but significant changes have also taken place. The machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable parts, small batches, complex shapes, and high precision requirements, and to achieve high-efficiency and automated custom machining.

Cnc Machining Overview

Numerical control machining refers to the processing in which the control system issues instructions to make the tool perform various movements that meet the requirements, and expresses the shape and size of the parts in the form of numbers and letters, as well as the custom machining technology requirements.

A CNC machine tool is a machine tool controlled by a computer. The computer used to control the machine tool, whether it is a special computer or a general-purpose computer, is collectively called a CNC system. The movement and auxiliary actions of the CNC machine tool are controlled by the instructions issued by the CNC system.

The instructions of the numerical control system are compiled by the programmer according to the material of the workpiece, the machining requirements, the characteristics of the machine tool, and the instruction format (numerical control language or symbols) prescribed by the system. The numerical control system sends out operation or termination information to the servo device and other functional components according to the program instructions to control various movements of the machine tool. When the part processing program ends, the machine tool will automatically stop. For any kind of CNC machine tool, if there is no program command input in the CNC system, the CNC machine tool cannot work. The controlled action of the machine tool roughly includes the start and stop of the machine tool; the start and stop of the spindle, the conversion of the rotation direction and the speed; the direction, speed, and mode of the feed movement; the selection of the tool, the compensation of the length and the radius; the replacement of the tool, and the cooling Liquid opening, closing, etc.

Numerical control technology originated from the needs of the aviation industry. In the late 1940s, a helicopter company in the United States put forward the initial idea of a CNC machine tool. In 1952, the Massachusetts Institute of Technology developed a three-axis CNC milling machine. This kind of CNC milling machine has been used for machining aircraft parts in the mid-1950s. In the 1960s, numerical control systems and programming work became increasingly mature and perfect. CNC machine tools have been used in various industrial sectors, but the aerospace industry has always been the largest user of CNC machine tools. Some large aviation factories are equipped with hundreds of CNC machine tools, of which cutting machines are the main ones. CNC machining parts include integral wall panels, beams, skins, bulkheads, propellers, and aircraft engine casings, shafts, disks, blades, and special cavity surfaces of liquid rocket engine combustion chambers. . The initial stage of the development of CNC machine tools is based on continuous trajectory CNC machine tools. Continuous trajectory control is also called contour control, which requires the tool to move on a prescribed trajectory relative to the part. Later, vigorously develop point-control CNC machine tools. Point position control means that the tool moves from one point to another, as long as it can reach the target accurately at the end, regardless of the moving route.

BE-CU.COM – As an accomplished CNC machining company and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]

The Operation Process Of Cnc Machining

What Is NC Programming

The programming method of NC machining can be divided into manual (manual) programming and automatic programming. Manual programming, the entire content of the program is manually written in accordance with the instruction format specified by the CNC system. Automatic programming is computer programming, which can be divided into automatic programming methods based on language and drawing. However, no matter what kind of automatic programming method is adopted, corresponding hardware and software are required.

It can be seen that the realization of CNC machining programming is the key. But programming alone is not enough. CNC machining also includes a series of preparatory work that must be done before programming and the aftermath of programming. Generally speaking, the main contents of CNC machining process are as follows:

- – Select and confirm the parts and contents for CNC machining;

- -Process analysis of CNC machining of parts drawings;

- -Process design of CNC machining;

- -Mathematical machining of parts drawings;

- -Compile the machining procedure list;

- -Make the control medium according to the procedure list;

- -Check and modify the program;

- -Trial machining of the first piece and on-site problem handling;

- -Finalizing and filing of NC machining process documents.

In order to improve the degree of production automation, shorten the programming time and reduce the cost of CNC machining, a series of advanced CNC machining technologies have been developed and used in the aerospace industry. For example, computer numerical control, that is, use a small or microcomputer to replace the controller in the numerical control system, and use the software stored in the computer to perform calculation and control functions.

This soft-connected computer numerical control system is gradually replacing the initial state of the numerical control system. Direct numerical control is to use one computer to directly control multiple numerical control machine tools, which is very suitable for small batch and short cycle production of aircraft. The ideal control system is an adaptive control system that can continuously change machining parameters. Although the system itself is complicated and expensive, it can improve machining efficiency and quality. In addition to the improvement of CNC systems and machine tools in terms of hardware, the development of CNC has another important aspect that is the development of software. Computer-aided programming (also called automatic programming) means that after a programmer writes a program in numerical control language, it is input into the computer for translation, and finally the computer automatically outputs punched tape or tape. The most widely used CNC language is the APT language.

It is roughly divided into main machining program and post processing program. The former translates the program written by the programmer to calculate the tool path; the latter compiles the tool path into the part machining program of the CNC machine tool. Numerical control machining is to write programs on the computer before machining the workpiece, and then input these programs into the machine tool controlled by the computer program for instructional processing, or write instructions directly on the machine tool control panel controlled by the computer program For cnc machining. The machining process includes: tool moving, tool change, speed change, direction change, parking, etc., all of which are completed automatically. CNC machining is an advanced method of modern mold manufacturing and machining. Of course, CNC machining methods must not only be used for mold parts machining, but also have a wide range of uses.

The Process Analysis Of Cnc Machining

The technical issues of CNC machining of processed parts involve a wide range of aspects. The following combines the possibility and convenience of programming to put forward some main content that must be analyzed and reviewed.

1.The dimensioning should conform to the characteristics of CNC machining

In CNC programming, the size and position of all points, lines, and surfaces are based on the programming origin. Therefore, it is best to give the coordinate size directly on the part drawing, or try to quote the size with the same datum.

2.The conditions of geometric elements should be complete and accurate

In programming, programmers must fully grasp the geometric element parameters that constitute the contour of the part and the relationship between the geometric elements. Because all geometric elements of the part contour must be defined during automatic programming, the coordinates of each node must be calculated during manual programming. No matter which point is unclear or uncertain, programming cannot be carried out. However, due to inadequate consideration or neglect by part designers in the design process, there are often incomplete or unclear parameters, such as arc and straight line, arc and arc whether they are tangent or intersecting or separated. Therefore, when reviewing and analyzing the drawings, you must be careful and contact the designer in time if you find any problems.

3.Reliable positioning datum

In CNC machining, the machining processes are often concentrated, and it is very important to locate on the same datum. Therefore, it is often necessary to set some auxiliary datums, or add some process bosses on the blank.

4.Uniform geometry type or size

It is better to adopt uniform geometric types or dimensions for the shape and inner cavity of parts, so as to reduce the number of tool changes, and it is also possible to apply control programs or special programs to shorten the program length. The shape of the parts is as symmetrical as possible, so that it is convenient to use the mirror machining function of the CNC machine tool to program, so as to save programming time.

The Part Clamping Of Cnc Machining

1.The basic principles of positioning and installation

When machining parts on a CNC machine tool, the basic principle of positioning and installation is to choose a reasonable positioning datum and clamping plan. Pay attention to the following points when choosing:

- Strive for a unified benchmark for design, process and programming calculations.

- Minimize the number of clamping times, and process all the surfaces to be processed after positioning and clamping once as much as possible.

- Avoid the use of machine-occupied and manual-adjustable machining schemes in order to give full play to the effectiveness of CNC machine tools.

2.The basic principles of choosing fixtures

The characteristics of CNC machining put forward two basic requirements for the fixture:

One is to ensure that the coordinate direction of the fixture is relatively fixed with the coordinate direction of the machine tool;

The second is to coordinate the size relationship between the parts and the machine coordinate system. In addition, the following points should be considered:

- When the batch of parts is not large, modular fixtures, adjustable fixtures and other general fixtures should be used as much as possible to shorten production preparation time and save production costs.

- Only consider the use of special fixtures during mass production, and strive to have a simple structure.

- The loading and unloading of parts should be fast, convenient and reliable to shorten the machine stop time.

- The parts on the fixture should not hinder the machining of the surface of the parts by the machine tool, that is, the fixture should be opened, and its positioning and clamping mechanism components should not affect the tool movement during machining (such as collisions, etc.).

3.Cnc Machining Error

Numerical control machining error △ addition is composed of programming error △ editing, machine tool error △ machine, positioning error △ fixed, tool setting error △ tool and other errors.

Namely: △number plus=f (△edit+△machine+△fix+△tool)

- Programming error △ is composed of approximation error δ and rounding error. The approximation error δ is produced in the process of approximating a non-circular curve with a straight line segment or a circular arc segment, as shown in Figure 1.43. The rounding error is the error produced by rounding the coordinate value to an integer pulse equivalent value during data machining. Pulse equivalent refers to the displacement of each unit pulse corresponding to the coordinate axis. Normal precision CNC machine tools generally have a pulse equivalent value of 0.01mm; more precise CNC machine tools have a pulse equivalent value of 0.005mm or 0.001mm, etc.

- The error of the machine tool is caused by the error of the CNC system and the feed system.

- The positioning error △ is always caused when the workpiece is positioned on the fixture and the fixture is positioned on the machine tool.

- Tool setting error △ tool is generated when determining the relative position of the tool and the workpiece.

The Main Feature Of Cnc Machining

Numerically controlled machine tools select aircraft parts with complex profiles as the processing objects from the very beginning, which is the key to solving the problem that ordinary machining methods are difficult to solve. The biggest feature of CNC machining is the use of punched tape (or tape) to control the machine tool for automatic processing. Because airplanes, rockets and engine parts have different characteristics: airplanes and rockets have zero parts, large component sizes, and complex shapes; engine zero, small component sizes, and high precision. Therefore, the CNC machine tools selected by the aircraft and rocket manufacturing departments and the engine manufacturing departments are different. In aircraft and rocket manufacturing, large-scale CNC milling machines with continuous control are mainly used, while in engine manufacturing, both continuous-control CNC machine tools and point-control CNC machine tools (such as CNC drilling machines, CNC boring machines, machining centers, etc.) are used .

The Process Concentration Of Cnc Machining

CNC machine tools generally have tool holders and tool magazines that can automatically change tools. The tool change process is automatically carried out under program control. Therefore, the process is relatively concentrated. Process concentration brings huge economic benefits:

- -Reduce the floor space of the machine tool and save the workshop.

- -Reduce or no intermediate links (such as intermediate inspection of semi-finished products, temporary storage and handling, etc.), which saves time and manpower.

The Automation Of Cnc Machining

When the CNC machine tool is processed, there is no need to manually control the tool, and the degree of automation is high. The benefits are obvious.

- -The requirements for operators are reduced: a senior worker of an ordinary machine tool cannot be trained in a short time, and a CNC worker who does not need programming has a very short training time (such as a CNC lathe worker needs one week, and he can also write simple machining program). In addition, the parts processed by CNC workers on CNC machine tools have higher precision than those processed by ordinary workers on traditional machine tools, and it takes less time.

- -Reduced labor intensity of workers: CNC workers are excluded from the processing most of the time during processing, which is very labor-saving.

- -Stable product quality: The processing automation of CNC machine tools eliminates the fatigue, carelessness, estimation and other human errors of workers on ordinary machine tools, and improves the consistency of products.

- -High machining efficiency: The automatic tool change of the CNC machine tool makes the processing process compact and improves labor productivity.

The High Flexibility Of Cnc Machining

Although traditional general-purpose machine tools are flexible, they are low in efficiency; while traditional special machines are highly efficient, but have poor adaptability to parts, high rigidity, and poor flexibility, making it difficult to adapt to the fierce competition in the market economy. Products are frequently remodeled. As long as the program is changed, new parts can be processed on the CNC machine tool, and it can be automated, with good flexibility and high efficiency. Therefore, the CNC machine tool can well adapt to market competition.

The Strong Ability Of Cnc Machining

The machine tool can accurately process various contours, and some contours cannot be machined on ordinary machine tools. CNC machine tools are especially suitable for the following occasions:

- Parts that are not allowed to be scrapped.

- Development of new products.

- Machining of urgently needed parts.

What Is CNC Programming

The Structure Of Cnc Programming

A program segment is a continuous group of words that can be processed as a unit, and it is actually a section of a program in a CNC machining program. The main body of the part machining program is composed of several program segments. Most program segments are used to instruct the machine tool to complete or execute a certain action. The block is composed of size words, non-size words and block end instructions. When writing and printing, each block generally occupies one line, and the same is true when the program is displayed on the screen.

The Format Of Cnc Program

The conventional machining program is composed of start character (single row), program name (single row), program body and program end instruction (generally single row). There is a program end character at the end of the program. The program start character is the same character as the program end character:% in ISO code, ER in EIA code. The program end instruction can be M02 (program end) or M30 (paper tape end). CNC machine tools generally use stored programs to run. At this time, the common point of M02 and M30 is: After completing all other commands in the program segment, they are used to stop the spindle, coolant and feed, and reset the control system. M02 and M30 are completely equivalent when used on some machine tools (systems), but the following differences are used on other machine tools (systems): When the program is ended with M02, the cursor stops at the end of the program after the automatic operation ends; and When the program is terminated by M3O, the cursor and screen display can automatically return to the beginning of the program after the automatic operation is over, and the program can be run again by pressing the start button. Although M02 and M30 allow to share a block with other program words, it is better to list them in a single block, or share a block with the sequence number only.

The program name is located before the main body of the program and after the start of the program, and it usually occupies a line on its own. The program name has two forms: one is composed of a prescribed English character (mostly O), followed by a number of digits. The maximum allowable number of digits is stipulated by the manual, and the two common ones are two digits and four digits. This form of program name can also be called a program number. Another form is that the program name is composed of English characters, numbers or a mixture of English and numbers, and a “-” sign can be added in the middle. This form allows users to name the program more flexibly. For example, the program for the third process of machining the flange with the part drawing number 215 on the LC30 CNC lathe can be named LC30-FIANGE-215-3, which can be used and stored And retrieval, etc. bring great convenience. The form of the program name is determined by the CNC system.

- %

- O1001

- N0 G92 X0 Y0 Z0

- N5 G91 G00 X50 Y35 S500 MO3

- N10 G43 Z-25 T01.01

- N15 G01 G007 Z-12

- N20 G00 Z12

- N25 X40

- N30 G01 Z-17

- N35 G00 G44 Z42 M05

- N40 G90 X0 Y0

- N45 M30

- %

The Segment Format Of Cnc Programming

The rules for the arrangement of words, characters and data in a program segment are called block format. The fixed sequence format and separator (HT or TAB) block format have been used in the history of CNC. When these two program segment formats have passed, the word address variable program segment format is widely used at home and abroad, also known as the word address format. In this format, the program word length is not fixed, and the number of program words is also variable. Most CNC systems allow the sequence of program words to be arranged arbitrarily, so it belongs to the variable block format. However, in most occasions, for the convenience of writing, inputting, checking and proofreading, program words are arranged in a certain order in the program segment.

The programming manual of CNC machine tools uses detailed format to classify and stipulate the details of programming: the characters used in programming, the sequence of program words in the program segment and the word length, etc. For example:/ NO3 G02 X+053 Y+053 I0 J+053 F031 S04 T04 M03 LF

The detailed format classification description of the above example is as follows: N03 is the sequence number of the block; G02 indicates that the machining track is a clockwise arc; X+053, Y+053 indicate the end point coordinates of the processed arc; I0, J+053 indicate the processed circle The center coordinate of the arc; F031 is the machining feed rate; S04 is the spindle speed; T04 is the tool number of the tool used; M03 is the auxiliary function command; the LF block end command; / is the skip selection command. The function of the skip selection instruction is: on the premise that the program remains unchanged, the operator can make a choice to execute or not to execute the block in the program that has the skip selection instruction. The method of selection is usually to switch the step selection switch on the operation panel to ON or OFF to realize that the program segment with “/” is not executed or executed.

Execute Program

This situation is sometimes encountered when compiling machining program: a group of blocks appears multiple times in a program, or it is used in several programs. We can extract this group of program segments, name them and store them separately, this group of program segments are subroutines. A subroutine is a section of machining program that can be called by an appropriate machine tool control instruction, and it generally has an independent meaning in CNC machining. The processing program where the instruction to call the subroutine of the first level is located is called the main program. The instruction of the subprogram is also a program segment, which is generally composed of the subprogram call instruction, the name of the subprogram, and the number of calls. The specific rules and format vary with the system. For example, it is also “call subprogram No.55 once”, FANUC system uses ” M98 P55.”, while the American AB system uses “P55x”.

Subroutines can be nested, that is, layer by layer. The relationship between the upper level and the next level is the same as the relationship between the main program and the first level subroutine. The maximum number of layers that can be set is determined by the specific CNC system. The form and composition of the subroutine are roughly the same as the main program: the first line is the subroutine number (name), the last line is the “subroutine end” instruction, and the main body of the subroutine is between them. However, the function of the main program end instruction is to end the main program and reset the CNC system. The instructions have been standardized, and each system uses M02 or M30; and the subroutine end instruction is used to end the subroutine and return to the main program or the upper subroutine. , Its commands are not unified in each system, such as M99 for FANUC system, M17 for Siemens system, M02 for system of American A-B company, etc.

User macros (programs) can be used in CNC machining programs. The so-called macro program is a subprogram that contains variables. The instruction that calls the macro program in the program is called the user macro instruction, and the function that the system can use the user macro program is called the user macro function. When executing, you only need to write the user macro command to execute its user macro function.

The biggest features of user macros are:

- Variables can be used in user macros;

- Arithmetic formulas, steering statements and various functions can be used

- You can use user macro commands to assign values to variables.

CNC machine tools use group technology to process parts, which can expand the batch size, reduce the amount of programming, and improve economic benefits. In the group machining, the parts are classified, and the machining program is compiled for this type of parts, without the need to program each part. When processing the same type of parts with different sizes, the main convenience of using user macros is that you can use variables to replace specific values. When actually processing, you only need to assign the actual size values of this part to variables with user macro commands.

The Processing Principle Of Cnc Machining

- -The machining of the previous process cannot affect the positioning and clamping of the next process.

- -First inside and then outside, that is, the inner cavity (inner hole) is processed first, and then the outer shape is processed.

- -Processing procedures with the same installation or using the same tool should be carried out continuously to reduce errors caused by repositioning or tool change.

- -In the same installation, the process that has less influence on the rigidity of the workpiece should be carried out first.

Cnc Machining Route

The feed machining route of the CNC lathe refers to the path that the turning tool moves from the tool setting point (or the fixed origin of the machine tool) until it returns to the point and ends the processing program, including the cutting path and the cutting path of the tool, cutting out and cutting out. Cut the empty stroke path.

The feed route of finishing is basically carried out along the part contour sequence. Therefore, the focus of determining the feed route is to determine the feed route of rough machining and idle stroke.

In CNC lathe machining, the determination of the processing route generally follows the following principles.

- ① It should be able to guarantee the accuracy and surface roughness of the workpiece to be processed.

- ② Make the machining route the shortest, reduce the idle travel time, and improve the processing efficiency.

- ③Simplify the workload of numerical calculation as much as possible and simplify the machining procedure.

- ④ For some reusable programs, subroutines should be used.

Making the machining program have the shortest feed route can not only save the execution time of the entire machining process, but also reduce some unnecessary tool consumption and the wear of the sliding parts of the machine tool’s feed mechanism. The type and realization method of the shortest feed path are as follows.

1.The shortest cutting feed route.

The cutting feed path is the shortest, which can effectively improve production efficiency and reduce tool loss. When arranging the shortest cutting feed route, it is also necessary to ensure the rigidity of the workpiece and the requirements of machining technology.

2. The shortest empty trip route.

- ① Use the starting point skillfully. An example of the general situation of rough turning using rectangular loop method. The setting of tool setting point A is to take into account the need for convenient tool change during finishing turning and other machining, so it is set at a position far away from the blank, and at the same time, the starting point and the tool setting point are overlapped.

- ②Set the tool change point ingeniously. In order to consider the convenience and safety of tool change, sometimes the tool change point is also set at a position far away from the blank. Then, when the second tool is changed, the empty stroke path during finishing turning must be longer; if If the tool change point of the second tool is also set at the non-point position in the middle, the idle stroke distance can be shortened.

- ③ Reasonably arrange the “return to zero” route. In order to simplify the calculation process and facilitate the verification when manually compiling the machining program of complex contours, the programmer sometimes returns the tool end point after each tool is processed by executing the “return to zero” operation instruction to make it all return to the tool setting point Position, and then perform subsequent procedures. This will increase the distance of the feed path and reduce production efficiency. Therefore, when rationally arranging the “return to zero” route, the distance between the end point of the previous cut and the start point of the next cut should be as short as possible. Or zero to meet the shortest feed path requirement. In addition, when selecting the command to return to the tool setting point, under the premise of no interference, use the x and z-axis bidirectional “zero return” command as much as possible. The function “zero return” route is the shortest.

3.Step cutting feed path of large margin blanks.

Two cutting feed routes for blanks with too much margin are listed. It is a wrong step cutting route. Cut in the order of 1 bucket and 5, and the margin left for each cutting is equal, which is the correct step cutting feed route. Because of the same amount of knife back.

4.Continuous cutting feed route for finishing part contour.

The finishing of the contour of the part can be arranged with one or several finishing processes. The finished contour should be processed continuously from the last cut. At this time, the tool’s forward and retreat positions should be selected appropriately. Try not to arrange cutting and cutting out or tool change and pause in the continuous contour, so as to avoid sudden changes in cutting force. And destroy the equilibrium state of the process system. Cause scratches, shape mutations or retained tool marks on the contour of the part.

5.Special feed route.

In CNC turning, under normal circumstances. The longitudinal feed of the tool is fed along the negative direction of the coordinate, but sometimes it is unreasonable to arrange the feed route in its normal negative direction. It may even damage the workpiece.

The Advantages And Disadvantage Of Cnc Machining

CNC machining has the following advantages:

- ① The number of tooling is greatly reduced, and complex tooling is not required for machining parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

- ② The processing quality is stable, the machining accuracy is high, and the repeat accuracy is high, which is suitable for the machining requirements of aircraft.

- ③ The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

- ④ It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable machining parts.

The disadvantage of CNC machining is that the cost of machine tool equipment is expensive and requires a high level of maintenance personnel.

The Tool Selection Of Cnc Machining

Choose Tool Process

1.The principle of choosing CNC tools

Tool life is closely related to cutting volume. When formulating the cutting parameters, the reasonable tool life should be selected first, and the reasonable tool life should be determined according to the optimization goal. Generally divided into the highest productivity tool life and the lowest cost tool life, the former is determined according to the goal of the least single-piece labor hours, and the latter is determined according to the goal of the lowest process cost.

When choosing tool life, you can consider the following points to choose according to the complexity of the tool, manufacturing and grinding costs. The life of complex and high-precision tools should be higher than that of single-edged tools. For machine-clamped indexable tools, due to the short tool change time, in order to give full play to its cutting performance and improve production efficiency, the tool life can be selected to be lower, generally 15-30min. For multi-tool machine tools, modular machine tools and automated machining tools where tool installation, tool change, and tool adjustment are more complicated, the tool life should be higher, and the reliability of the tool should be ensured in particular. When the productivity of a certain process in the workshop limits the improvement of the productivity of the entire workshop, the tool life of the process should be selected lower. When the cost of the whole plant per unit time of a certain process is relatively large, the tool life should also be selected Lower. When finishing large parts, in order to ensure that at least one pass is completed and to avoid changing the tool in the middle of cutting, the tool life should be determined according to the accuracy of the part and the surface roughness. Compared with ordinary machine tool processing methods, CNC machining puts forward higher requirements on cutting tools. It not only requires good quality and high precision, but also requires dimensional stability, high durability, and easy installation and adjustment. Meet the high efficiency requirements of CNC machine tools. The selected tools on CNC machine tools often adopt tool materials suitable for high-speed cutting (such as high-speed steel, ultra-fine-grained cemented carbide) and use indexable inserts.

2.Choose tools for CNC turning

The commonly used CNC turning tools are generally divided into three categories: forming tools, pointed tools, arc tools and three types. Forming turning tools are also called prototype turning tools, and the contour shape of the machined parts is completely determined by the shape and size of the turning tool blade. In CNC turning processing, common forming turning tools include small radius arc turning tools, non-rectangular turning tools and threading tools. In CNC machining, the forming turning tool should be used as little as possible or not. The pointed turning tool is a turning tool characterized by a straight cutting edge. The tool tip of this type of turning tool is composed of linear main and secondary cutting edges, such as 900 internal and external turning tools, left and right face turning tools, grooving (cutting) turning tools, and various external and internal cutting edges with very small tip chamfers. Hole turning tool. The selection method of the geometric parameters of the pointed turning tool (mainly the geometric angle) is basically the same as that of ordinary turning, but the characteristics of CNC machining (such as machining route, machining interference, etc.) should be considered comprehensively, and the tool tip itself should be considered. strength.

The second is the arc-shaped turning tool. The arc-shaped turning tool is a turning tool characterized by an arc-shaped cutting edge with a small roundness or linear profile error. Each point of the arc edge of the turning tool is the tip of the arc-shaped turning tool. Accordingly, the tool position point is not on the arc, but on the center of the arc. The arc-shaped turning tool can be used for turning inner and outer surfaces, and is especially suitable for turning various smooth connection (concave) forming surfaces. When selecting the arc radius of the turning tool, it should be considered that the arc radius of the cutting edge of the two-point turning tool should be less than or equal to the minimum curvature radius on the concave contour of the part, so as to avoid processing dryness. The radius should not be selected too small, otherwise it will not only be difficult to manufacture, The turning tool may also be damaged due to weak tool tip strength or poor heat dissipation capacity of the tool body.

3.Choose tools for CNC milling

In CNC machining, flat-bottomed end mills are commonly used for milling the inner and outer contours of plane parts and milling planes. The empirical data of the relevant parameters of the tool are as follows: First, the radius of the milling cutter should be smaller than the minimum radius of curvature Rmin of the inner contour surface of the part, generally RD= (0.8-0.9) Rmin. The second is the machining height of the part H< (1/4-1/6) RD to ensure that the knife has sufficient rigidity. Third, when milling the bottom of the inner groove with a flat-bottomed end mill, because the two passes of the groove bottom need to be overlapped, and the radius of the bottom edge of the tool is Re=Rr, that is, the diameter is d=2Re=2(Rr), when programming Take the tool radius as Re=0.95 (Rr). For the processing of some three-dimensional profiles and contours with variable bevel angles, spherical milling cutters, ring milling cutters, drum milling cutters, tapered milling cutters and disc milling cutters are commonly used.

Most of the CNC machine tools use serialized and standardized tools. For the tool holders and heads of indexable machine-clamped external turning tools, face turning tools, etc., there are national standards and serialized models. For machining centers and automatic tool changers Machine tools and tool holders have been serialized and standardized. For example, the standard code of the tapered tool system is TSG-JT, and the standard code of the straight tool system is DSG-JZ. In addition, for the selected tool, Before use, the tool size needs to be strictly measured to obtain accurate data, and the operator enters these data into the data system, and completes the processing process through program call, thereby processing qualified workpieces.

Knife point

From what position does the tool start to move to the specified position? So at the beginning of the program execution, you must determine the position where the tool starts to move in the workpiece coordinate system. This position is the starting point of the tool relative to the workpiece when the program is executed. So it is called the program starting point or starting point. This starting point is generally determined by tool setting, so this point is also called the tool setting point. When compiling the program, the position of the tool setting point must be selected correctly. The principle of setting the tool setting point is to facilitate numerical processing and simplify programming. It is easy to align and check during processing; the processing error caused is small. The tool setting point can be set on the machined part, on the fixture or on the machine tool. In order to improve the machining accuracy of the part, the tool setting point should be set as far as possible on the part’s design reference or process base. In actual operation of the machine tool, the tool position point of the tool can be placed on the tool setting point by manual tool setting operation, that is, the coincidence of the “tool position point” and the “tool setting point”. The so-called “tool location point” refers to the positioning datum point of the tool, and the tool location point of the turning tool is the tool tip or the center of the tool tip arc. The flat-bottomed end mill is the intersection of the tool axis and the bottom of the tool; the ball-end mill is the center of the ball, and the drill is the point. Manual tool setting operation has low precision and low efficiency. Some factories use optical tool setting mirrors, tool setting instruments, automatic tool setting devices, etc. to reduce tool setting time and improve tool setting accuracy. When the tool needs to be changed during processing, the tool change point should be specified. The so-called “tool change point” refers to the position of the tool post when it rotates to change the tool. The tool change point should be located outside the workpiece or fixture, and the workpiece and other parts should not be touched during the tool change.

Cutting Amount

In NC programming, the programmer must determine the cutting amount of each process and write it in the program in the form of instructions. Cutting parameters include spindle speed, back-cutting amount and feed speed, etc. For different processing methods, different cutting parameters need to be selected. The selection principle of the cutting amount is to ensure the machining accuracy and surface roughness of the parts, give full play to the cutting performance of the tool, ensure reasonable tool durability, and give full play to the performance of the machine tool to maximize productivity and reduce costs.

1.Determine the spindle speed

The spindle speed should be selected according to the allowable cutting speed and the diameter of the workpiece (or tool). The calculation formula is: n=1000 v/7 1D where: v? Cutting speed, the unit is m/m movement, which is determined by the durability of the tool; n is the spindle speed, the unit is r/min, and D is the diameter of the workpiece Or tool diameter, in mm. For the calculated spindle speed n, the speed that the machine tool has or is close to it should be selected at last.

2.Determine the feed rate

Feed speed is an important parameter in the cutting parameters of CNC machine tools, which is mainly selected according to the machining accuracy and surface roughness requirements of the parts and the material properties of the tools and workpieces. The maximum feed rate is limited by the rigidity of the machine tool and the performance of the feed system. The principle of determining the feed rate: When the quality requirement of the workpiece can be guaranteed, in order to improve the production efficiency, a higher feed rate can be selected. Generally selected within the range of 100-200mm/min; when cutting, processing deep holes or processing with high-speed steel tools, a lower feed speed should be selected, generally within the range of 20-50mm/min; when the processing accuracy, the surface When the roughness requirements are high, the feed speed should be smaller, generally within the range of 20-50mm/min; when the tool is empty, especially when the long distance “returns to zero”, you can set the CNC system settings of the machine tool The highest feed rate.

3.Determine the amount of back knife

The amount of back-grabbing is determined by the rigidity of the machine tool, workpiece and cutting tool. When the stiffness allows, the amount of back-grabbing should be equal to the machining allowance of the workpiece as much as possible, which can reduce the number of passes and improve production efficiency. In order to ensure the quality of the machined surface, a small amount of finishing allowance can be left, generally 0.2-0.5mm. In short, the specific value of the cutting amount should be determined by analogy based on the performance of the machine tool, related manuals and actual experience.

At the same time, the spindle speed, cutting depth and feed speed can be adapted to each other to form the best cutting amount.

Cutting amount is not only an important parameter that must be determined before machine tool adjustment, but also whether its value is reasonable or not has a very important influence on processing quality, processing efficiency, and production cost. The so-called “reasonable” cutting amount refers to the cutting amount that makes full use of the cutting performance of the tool and the dynamic performance (power, torque) of the machine tool to obtain high productivity and low processing cost under the premise of ensuring quality.