Using lasers to interact with substances to process or shape according to certain requirements is collectively referred to as optical manufacturing.

In the past 20 years, optical manufacturing technology has penetrated into high-tech fields and industries, and has begun to replace or transform some traditional processing industries.

In the automobile industry of developed countries, 50%-70% of the parts are completed by laser processing. Optical manufacturing technology is playing an increasingly important role in improving the R&D and manufacturing level of the automotive industry.

The Characteristics Of Optical Manufacturing Technology

At present, the light source used in optical manufacturing technology is mainly laser. The laser beam has the characteristics of high energy density, high single palladium and high directivity, which makes the optical manufacturing technology have many advantages over the traditional manufacturing technology. The tool used in this technology is a “laser knife”, which has no tool wear during processing; no cutting force affects the workpiece during processing, so the workpiece has no cold working deformation; due to the high energy injection speed during processing, the thermal impact on the workpiece is very small, so The thermal deformation of the workpiece is very small, and it can approach or reach the “cold” processing state, realizing high-precision manufacturing that cannot be performed by conventional technologies; the laser has good spatial controllability (beam direction change, rotation, scanning, etc.) and time controllability (opening , off, pulse interval), especially suitable for automatic processing, with high production efficiency in large-scale manufacturing; the material, shape, size and processing environment of the laser processing object have a large degree of freedom; low noise, no harmful rays and Residues, the production process has little pollution to the environment; it can save molds, shorten the product development cycle, and reduce development costs; less material waste, and low manufacturing costs in large-scale production.

The Categories Of Light Manufacturing Technology In The Automotive Industry

Optical manufacturing technology in the automotive industry can be divided into three categories: optical “cold” processing, optical “hot” processing, and optical rapid prototyping.

1.Light “cold” processing technology

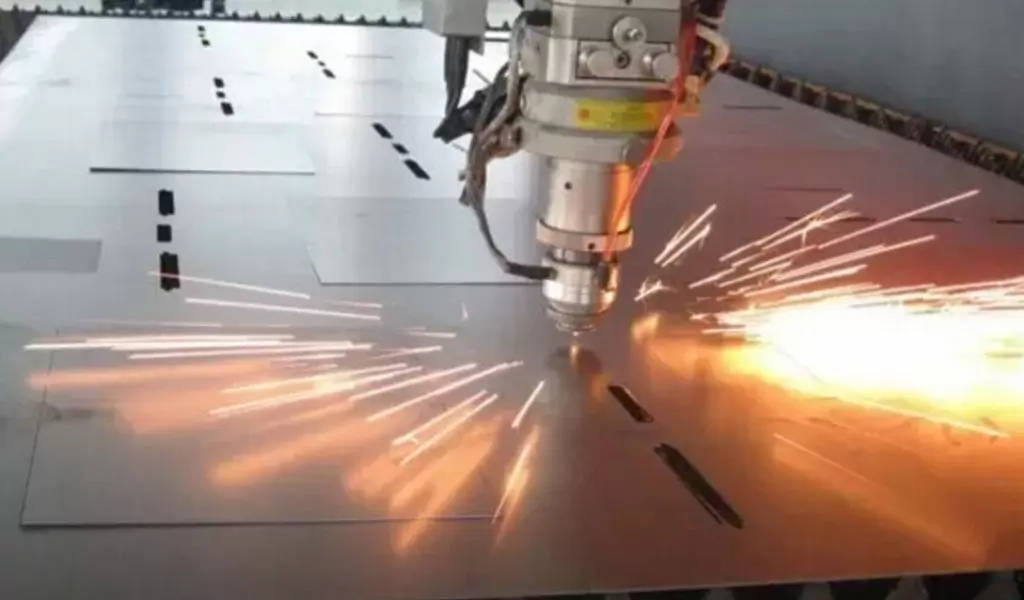

The optical manufacturing technologies corresponding to the conventional cold working process are laser cutting, laser drilling, laser marking and laser cutting.

The laser cutting speed is fast, the incision is smooth and flat, the parallelism of the trimming edge is good, and there is no follow-up processing;

Laser drilling has high speed and high efficiency, and is suitable for the processing of large number and high-density group holes; laser drilling can obtain a large aspect ratio, and can be processed on various materials such as hard, brittle, and soft, and even in Small holes are processed on the inclined surface of difficult-to-machine materials; the process of laser drilling is clean and pollution-free.

Laser marking is non-contact marking, fast, and the marking is not easy to wear, and the laser marking machine is easy to combine with the assembly line.

Laser cutting is a process similar to milling in machining, which uses a focused laser beam to cut material layer by layer.

2.Optical “thermal” processing technology

Optical manufacturing technologies corresponding to conventional thermal processing processes include laser welding, laser surface strengthening, laser cladding and alloying.

Laser welding is a process in which a high-intensity laser beam is used to locally heat the metal to be welded to above the melting temperature and fuse to form a welded joint. It can weld high melting point metals, non-metals, composite materials and other special materials, and can also realize the welding of dissimilar materials and the welding of special structures; the welding seam has the effect of “self-purification”, and the quality of the welding seam is high; it can be accurately welded, and generally does not require Filling metal; the laser beam and multiple equipments form a flexible processing system through the light guide system, the welding automation degree is high, and the production efficiency is high; in high-energy beam welding, the biggest feature of laser welding is that it does not require a vacuum chamber and does not generate x-rays .

Laser surface strengthening is divided into two types: laser phase transformation hardening and laser fusion hardening. Laser phase transformation hardening is also known as laser quenching. It scans the workpiece quickly with a high-energy laser beam, so that the surface temperature of the irradiated metal or alloy rises above the phase point at an extremely fast speed. When the laser beam leaves the irradiated part, Due to the effect of heat conduction, the matrix in the cold state is rapidly cooled and quenched by self-cooling, and a finer hardened layer structure is obtained, and the hardness is generally higher than that of conventional quenching; The heating temperature on the surface of the material is higher, and a layer of flame-hardened layer with fine structure is formed on the surface of the final part.

Laser cladding is the use of high-energy laser beams to irradiate the cladding material to rapidly fuse with the thin layer on the surface of the substrate to form an alloy coating with completely different compositions and properties that is metallurgically combined with the substrate.

3.Light rapid prototyping technology

The principle of optical rapid prototyping technology is that under the control of the computer, according to the design model and data of the part, such as cad, the molding material is cured layer by layer with a laser beam, the surface (layer) of the part is constructed by points and lines, and the surface is accurately accumulated into three-dimensional. The process of a solid model or part. The use of light rapid prototyping technology can significantly shorten the product development cycle, greatly reduce the development cost, quickly produce products that adapt to market changes, and maintain and strengthen the competitiveness of products in the market. At the same time, the use of light rapid prototyping technology is also an effective technical way to achieve concurrent engineering and agile manufacturing.

Entering the new century, the automobile industry is entering a lean production stage that can perform flexible processing according to user requirements. Flexible modular production methods have emerged in the automobile industry. The modern automobile industry is also developing in the direction of high-tech technology. The transformation of traditional mechanical manufacturing technology to advanced manufacturing technology. Light manufacturing technology has injected vitality into the development and production of automobiles. It can be expected that the application of optical manufacturing technology in the automobile industry will develop rapidly in this century, and it will become an important processing method in the automobile industry.