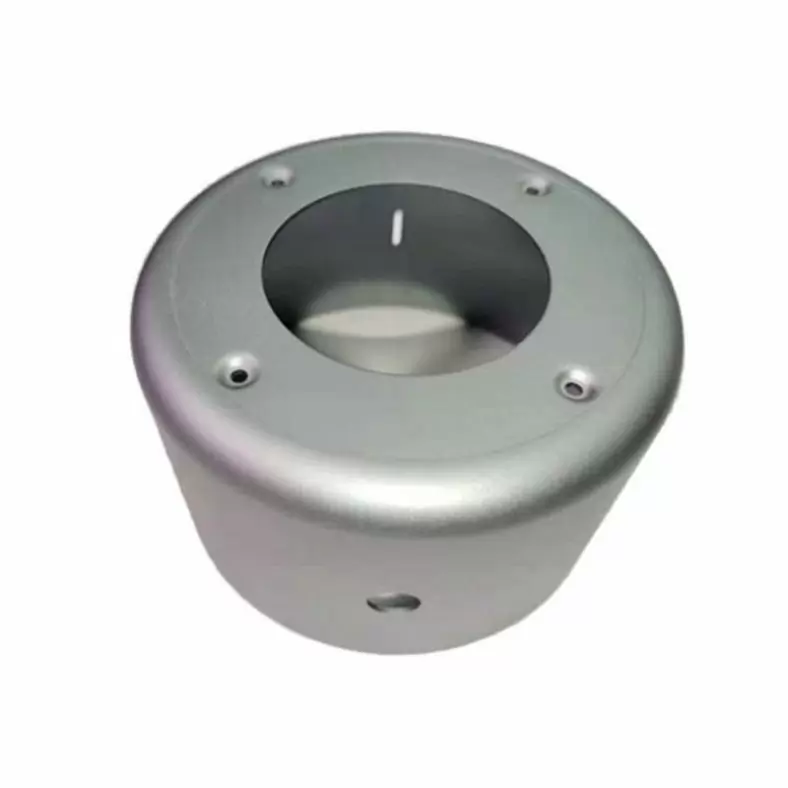

Connection Plate Assembly

- Material: Aluminum

- Stamping Size: Custom Size

- Stamping Type: Metal Forming

- Stamping Mold: Compound Mold

- Tolerance: Custom

- Fine Blanking Method: Multi-Station

- Surface Treatment: Custom

- Type: Automotive Stamping

High-Quality Stamping Motor Vehicle Connection Plate Assembly

ISO 9001:2015 and ISO/TS 16949:2002 registered custom manufacturer of metal stampings and fully sutomated automotive Motor Vehicle Connection Plate Assembly with fully automated resistance projection welding, critical features checked 100 percent by an automated non-contact gauging system. Types of stampings progressive and compound die stampings. Materials used for stampings include stainless and galvanized steel, aluminum, bronze and other non-ferrous materials. Pressing, heat-treating, welding, brazing, deburring, plating, engineering and CAD designing services are available for stampings.

Why Choose Our Stamping Motor Vehicle Connection Plate Assembly Service?

- Are Cost-Efficient

- Manufacture Parts That Are Precision-Built

- Expert-Level Consultation and Design Assistance

- Provide Free Tool & Die Insert Storage and Maintenance

- Offer Complete In-House Tool & Die Capabilities

- BE-CU And His Core Supplier Sipx has large to small precision stamping presses. Our presses range from 40 to 700 tons, with bed sizes up to 150 inches and speeds up to 400 strokes per minute.

- Specializing in automated precision progressive dies, our feed capability ranges from 0.008 to 0.375 inch thick material with coil widths up to 50 inches and weights to 15,000 pounds.

Advanced Equipment to Create a Diverse Range of Designs,Sizes, and Thicknesses Large or Small Parts Can Be:

- – Pierced

- – Formed

- – Drawn

- – Extruded

- – Marked

- – And More!

Expert-Level Consultation and Design Assistance including:

- Engineering drawing analysis

- Design feasibility reviews

- Functionality assessments

- Confirmation of supply tolerances, cost ratios, and other important project considerations

- Informed recommendations about when to use stamping versus other technologies

Contact Be Cu Now for your Custom Metal Stamping, We are your best online Stamping services choice!

Specifications of Stamping Motor Vehicle Connection Plate Assembly

| Raw Material Thickness | 0.040″ to 0.375″ |

| Material | Aluminum (3003, 5052, 6061), Cold Rolled Steel (1008, 1010), High Carbon Steel (1035), Nickel and Pre-plated Steel, Galvannealed Steel, Brass (80-20, 80-15, 70-30), Copper, HSLA. |

| Presses Ranging | 40 to 700 tons |

| Stamping Process | Flanging, punching, bending, necking, trimming, deep drawing, cold extrusion, precision blanking, bulging,Perforated ,Electroplating ,Oxidized, spray paint . |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Perforated ,Electroplating, spray paint ,Oxidized. |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU Metal Stamping Company

BE-CU.COM is a China based manufacturer offering Metal Forming services. Our plant specializes in Stamped Metal parts, post machining services and plating or painting. We press a comprehensive range of standard and complex custom shapes and some very challenging designs. With number of processes under one roof we manufacture all sort of products and offer assembly services.Your part drawings will be reviewed in house by be-cu engineers. The press will be designed around the profile according to the intended use for the metal part. Some design considerations, such as wall thickness, tolerances ant type of the metal may need to be taken into account. Off-tool samples will be provided to you after drawings are approved and tool been made.Our team of assemblers specialize in mechanical and electrical assembly of components. We are experienced with a large variety of assembly from simple one or two part additions to complete complex cabinets and assemblies. Additional services also include but not limited to Powdercoating, Plating, E-Coating, General Engineering and custom packaging.