In the realm of modern science and technology, X-ray inspection has emerged as an indispensable tool for various fields, ranging from medicine and industry to security and research. It is a groundbreaking imaging technique that allows us to peer into the hidden world of objects and materials by harnessing the power of high-energy electromagnetic radiation known as X-rays. In this comprehensive article, we will delve into the fundamental principles behind X-ray inspection, its historical evolution, its applications in diverse sectors, the safety measures implemented to protect both professionals and subjects involved, the cutting-edge advancements driving the future of X-ray technology, and the ethical considerations surrounding its usage.

The Birth of X-Rays: The Serendipitous Discovery that Revolutionized Science

The fascinating journey of X-rays began in 1895 when the German physicist Wilhelm Conrad Roentgen made one of the most profound discoveries in the history of science. During his experiments with cathode-ray tubes, he noticed an unusual glow in the vicinity of the tube. Intrigued, he began investigating this phenomenon and eventually realized that a new form of penetrating radiation was responsible for the mysterious glow. Roentgen aptly named these rays “X-rays,” as X is the mathematical symbol for an unknown quantity.

Roentgen’s groundbreaking work not only earned him the first Nobel Prize in Physics in 1901 but also opened up an entirely new field of research and application. The discovery of X-rays marked the beginning of the era of modern medical diagnostics, non-destructive testing, radiography, and a myriad of other groundbreaking applications.

The Physics Behind X-Ray Generation: The Invisible Light

To understand X-ray inspection, it is essential to comprehend the principles behind X-ray generation. X-rays are a type of high-energy electromagnetic radiation, similar to visible light but with significantly shorter wavelengths and higher frequencies. They are produced when high-speed electrons collide with a metal target, typically tungsten, in a process known as “bremsstrahlung” or “braking radiation.” Additionally, characteristic X-rays are produced when electrons knock out inner-shell electrons from the target atoms, and outer-shell electrons fill these vacancies.

This section will delve into the physics behind X-ray generation, including the role of cathode-ray tubes, X-ray tubes, and X-ray generators in producing these powerful rays. The concepts of wavelength, energy, and penetration will be discussed to lay the foundation for understanding X-ray imaging.

How X-Ray Imaging Works: Unveiling the Subsurface World

X-ray imaging, also known as radiography, relies on the differential absorption of X-rays by various materials. When X-rays pass through an object, they can either be absorbed, transmitted, or scattered, depending on the object’s density and composition.

A detector on the opposite side of the object captures the transmitted X-rays, and the data is processed to create an X-ray image, revealing internal structures and defects.

This section will explore the principles of X-ray imaging, including the role of X-ray detectors and image processing techniques. It will cover the fundamental concepts of attenuation and contrast, explaining how different materials interact with X-rays to create distinctive images. The process of X-ray image formation, including analog and digital imaging, will be detailed.

Types of X-Ray Inspection Techniques: Peering into the Invisible World

X-ray inspection encompasses various techniques, each tailored to specific applications:

- a. Radiography: The most common X-ray inspection method, radiography is widely used in medicine and industrial applications. It involves capturing 2D images of an object’s internal structure, revealing fractures, foreign objects, or defects. Radiography has been a cornerstone of medical diagnostics for decades, helping physicians diagnose bone fractures, lung conditions, and dental problems.

- b. Computed Tomography (CT): CT scanning combines multiple X-ray images taken from different angles to create detailed 3D images of the object. It offers superior visualization and is employed in medical diagnosis, non-destructive testing (NDT) of materials, and archaeology. CT scans have transformed medical imaging, providing unparalleled insights into internal organs and structures.

- c. Fluoroscopy: Fluoroscopy is a real-time X-ray imaging technique commonly used in medical procedures, such as guided interventions and barium studies. It allows dynamic visualization of internal processes, such as the movement of contrast agents through blood vessels.

- d. Digital Radiography (DR): DR is an advanced digital version of conventional radiography, offering quicker image acquisition and improved image quality. It has replaced traditional film-based radiography in many applications, providing higher resolution and dose reduction.

- e. Industrial X-Ray: In industrial applications, X-ray inspection is used for quality control, identifying defects in manufacturing processes, and inspecting critical components like welds and castings. Industrial X-ray systems play a crucial role in ensuring the safety and reliability of various products, including aerospace components and automotive parts.

- f. Cone Beam CT (CBCT): CBCT is a specialized form of CT imaging used in dentistry and maxillofacial surgery. It provides detailed 3D images of the dental and facial structures, aiding in treatment planning and diagnosis.

X-Ray Inspection in Medicine and Healthcare: Peering into the Human Body

X-ray imaging has revolutionized the field of medicine and healthcare, offering a non-invasive means to visualize and diagnose various medical conditions. This section will explore the wide-ranging applications of X-ray inspection in medicine, including:

- a. Diagnostic Radiology: X-ray imaging is a crucial diagnostic tool in medicine, assisting doctors in detecting bone fractures, tumors, dental issues, and other medical conditions. It plays a central role in orthopedics, dentistry, and emergency medicine.

- b. Interventional Radiology: Interventional radiologists use X-ray guidance to perform minimally invasive procedures, such as angiography, stent placement, and tumor ablation. Fluoroscopy and digital subtraction angiography (DSA) are commonly employed in these procedures.

- c. Radiotherapy: In radiation oncology, X-rays are used to deliver precise doses of radiation to cancerous tumors while sparing healthy tissues. This section will discuss the principles of radiotherapy and how X-ray machines are used in cancer treatment.

- d. Mammography: Mammography is a specialized X-ray technique for breast imaging, crucial in the early detection of breast cancer. The section will explore the advancements in digital mammography and tomosynthesis, enhancing breast cancer screening.

Non-Destructive Testing (NDT) and X-Ray Inspection in Industry

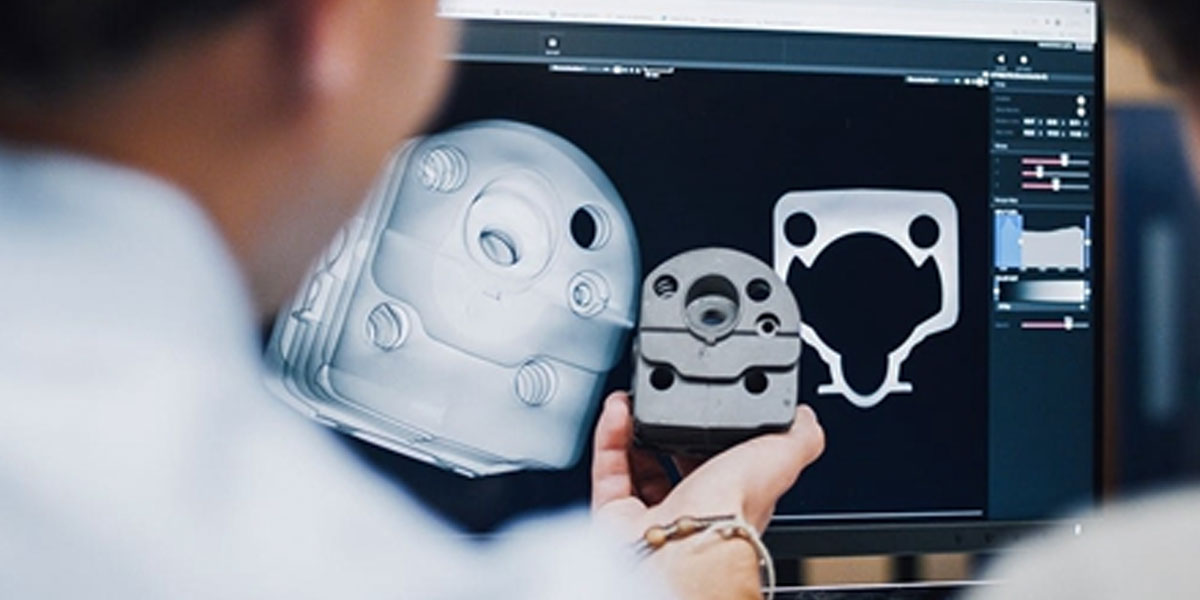

In engineering and manufacturing, non-destructive testing (NDT) is essential to detect defects and weaknesses in materials and structures without causing damage. This section will focus on how X-ray inspection plays a vital role in NDT and industrial applications:

- a. X-Ray Weld Inspection: Welds in metal structures are critically examined using X-ray inspection to ensure the integrity of welded joints in various industries, such as construction, aerospace, and pipeline infrastructure.

- b. Castings and Forgings Inspection: X-ray inspection helps identify internal defects, porosities, and inclusions in metal castings and forgings, ensuring that components meet stringent quality standards.

- c. Electronics and Semiconductor Manufacturing: In electronics production, X-ray inspection is used to detect defects like solder joint fractures and voids in electronic components. This section will discuss how X-ray inspection contributes to the reliability of electronic devices.

- d. Pipeline Inspection: X-ray inspection is employed in the energy sector to inspect pipelines for defects, corrosion, and material degradation. It helps prevent catastrophic failures and ensures the safe transportation of oil, gas, and other fluids.

- e. Bridge and Infrastructure Inspection: X-ray inspection is used to assess the integrity of aging bridges and infrastructure, ensuring their safety and structural stability.

X-Ray Inspection in Security and Border Control: Safeguarding Nations

X-ray scanners are employed in airports, seaports, and border checkpoints to inspect luggage, cargo, and vehicles for prohibited or hazardous items. This section will explore the role of X-ray inspection in security and border control, including:

- a. Baggage Screening: X-ray scanners are used for baggage screening at airports and transportation hubs to detect potentially dangerous items concealed within luggage.

- b. Cargo Inspection: In seaports and freight terminals, X-ray scanners inspect shipping containers and cargo for contraband, weapons, and hazardous materials.

- c. Vehicle Inspection: X-ray scanners are used at border crossings and checkpoints to scan vehicles for hidden contraband, drugs, and illegal immigrants.

X-Ray Inspection in Art Conservation and Archaeology: Unveiling the Past

X-ray imaging helps archaeologists and art conservators examine ancient artifacts and paintings non-invasively, revealing hidden details and structures without damaging the objects. This section will focus on the applications of X-ray inspection in art conservation and archaeology, including:

- a. Examination of Artifacts: X-ray inspection is used to explore the internal structures of ancient artifacts, such as pottery and metal objects, providing insights into their manufacturing techniques and historical significance.

- b. Artwork Analysis: X-ray imaging helps art conservators analyze paintings, revealing hidden layers, underlying sketches, and changes made by the artists during the creative process.

- c. Archaeological Excavation: X-ray inspection is employed during archaeological excavations to study the contents of burial sites and analyze the integrity of fragile artifacts before extensive restoration.

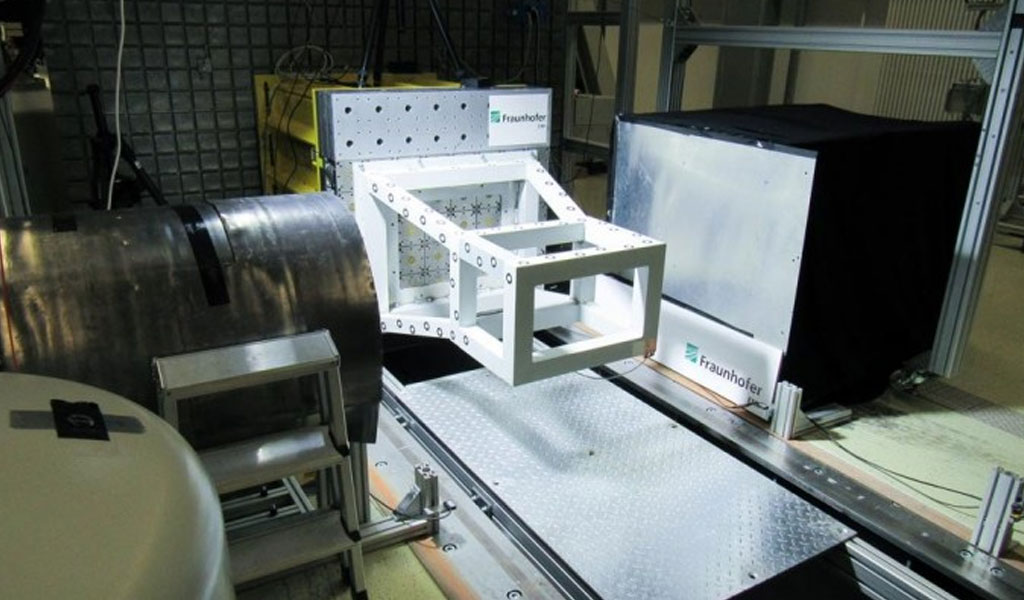

Advancements in X-Ray Inspection Technology: Paving the Way to the Future

X-ray inspection technology continues to advance rapidly, leading to improved image quality, reduced radiation doses, and enhanced capabilities. This section will explore some of the recent innovations and cutting-edge developments in X-ray inspection technology, including:

- a. Photon Counting Detectors: Photon counting detectors offer higher spatial resolution and energy discrimination, leading to better image quality and dose reduction.

- b. Dual-Energy X-ray Imaging: Dual-energy X-ray imaging provides enhanced material discrimination, enabling better differentiation of different materials and structures.

- c. Tomosynthesis and Phase-Contrast Imaging: These techniques offer 3D reconstruction and enhanced soft tissue imaging, revolutionizing medical diagnostics and research.

- d. AI and Machine Learning in X-Ray Interpretation: Artificial intelligence and machine learning algorithms are being developed to assist in X-ray image interpretation, improving accuracy and efficiency in diagnosis.

Safety Considerations in X-Ray Inspection: Shielding the Invisible Threat

While X-ray inspection offers valuable insights, it also poses potential health hazards due to the ionizing nature of X-rays. Proper safety measures must be strictly followed to protect operators, patients, and individuals undergoing X-ray examinations.

This section will address the importance of radiation safety, the principles of dose optimization, and the role of regulatory bodies in ensuring X-ray safety.

Ethical Considerations in X-Ray Inspection: Balancing Utility and Privacy

The extensive use of X-ray inspection raises important ethical considerations. This section will explore the ethical implications of X-ray imaging in various applications, such as healthcare, security, and archaeology. Topics to be discussed include patient consent, privacy concerns, informed consent in research, and the responsible use of X-ray inspection technology.

Conclusion: Illuminating the Invisible – The Ever-Evolving World of X-Ray Inspection

X-ray inspection has revolutionized various industries, enabling us to see the unseen and explore the internal structures of objects and materials. From healthcare to aerospace, its applications have improved the quality of our lives and ensured the safety and reliability of critical components. With continued advancements in technology and safety protocols, X-ray inspection will undoubtedly remain a cornerstone of modern science, continuing to unveil the hidden world with its subatomic vision. However, as we venture further into the future of X-ray inspection, it is crucial to balance the benefits with ethical considerations and ensure that this powerful technology is used responsibly, protecting both human health and privacy. The journey of X-ray inspection is far from over, and it promises to shine even brighter in illuminating the invisible world that surrounds us.