Cnc Machining Beryllium Copper C17500

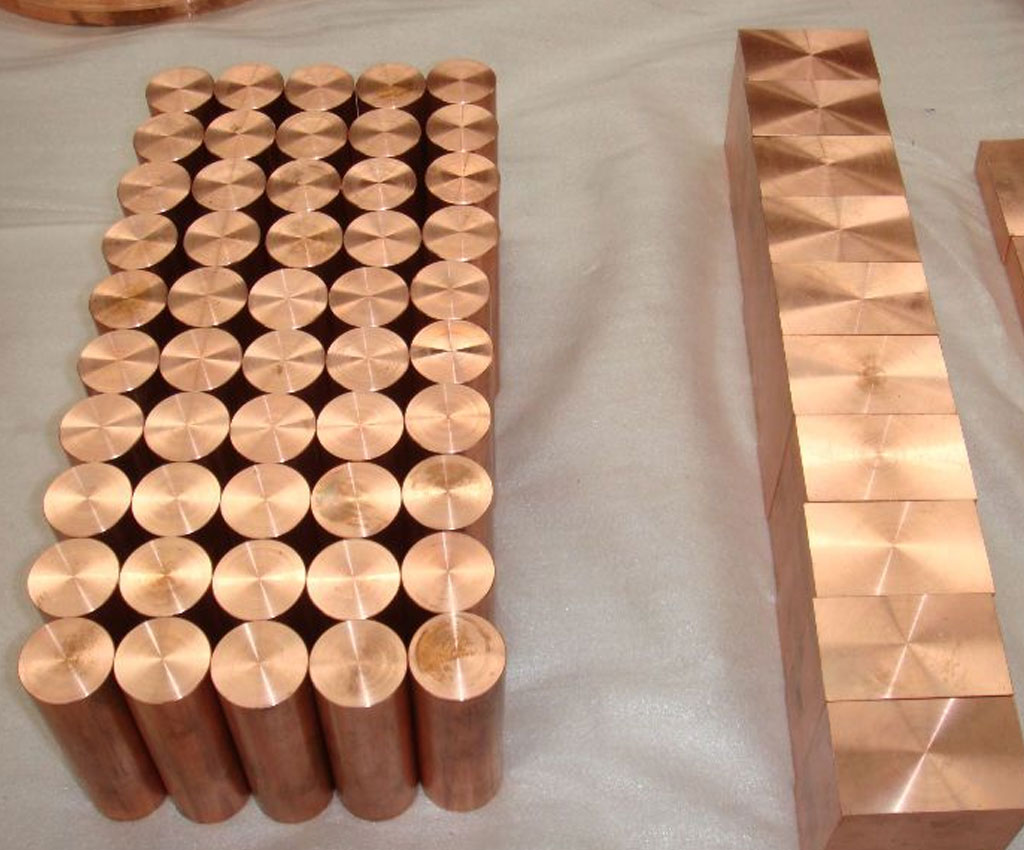

Beryllium Copper C17500 is a copper alloy that contains approximately 1.9-2.3% beryllium and around 0.2-0.6% cobalt. It is part of the copper beryllium alloy family and is also known by other names such as Alloy 3B, Alloy M25, and RWMA Class 3.

Beryllium Copper C17500 Machining

Beryllium Copper C17500 is a widely used material in the mold manufacturing industry due to its excellent electrical conductivity, corrosion resistance, and thermal conductivity. It is a high strength, high heat dissipation, and ductile metal that can be easily formed into complex shapes and is suitable for various CNC machining processes.

Beryllium Copper C17500 can generate heat during machining. Using an appropriate coolant or lubricant helps dissipate heat and improve the surface finish. Consult with Beryllium Copper machining suppliers to select the most suitable process for machining Beryllium Copper C17500. However, with the right techniques and equipment, high-quality parts can be produced efficiently and accurately from this versatile material.

Make Machined C17500 With Be-cu

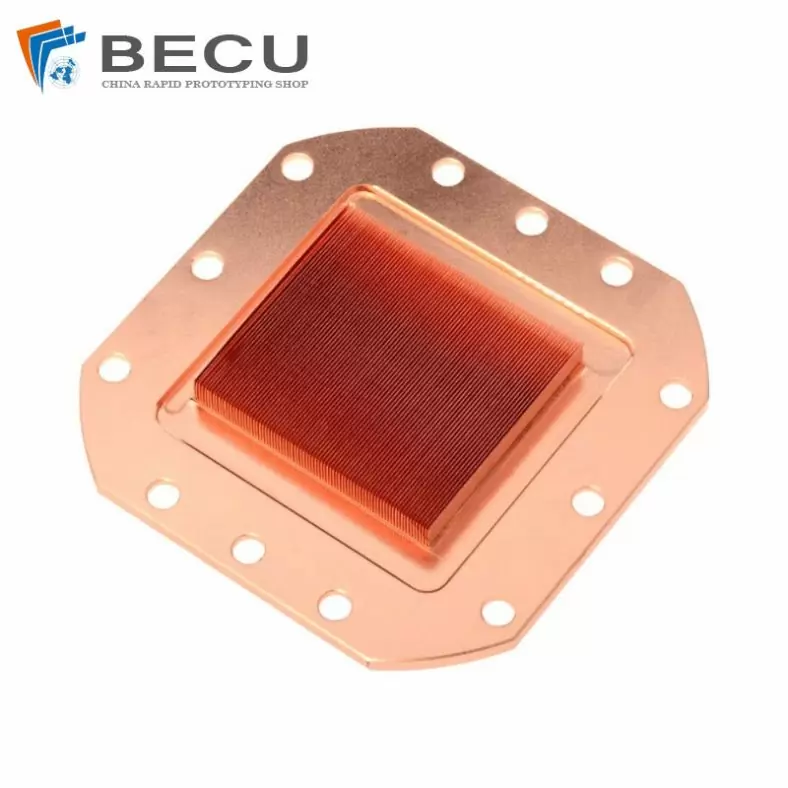

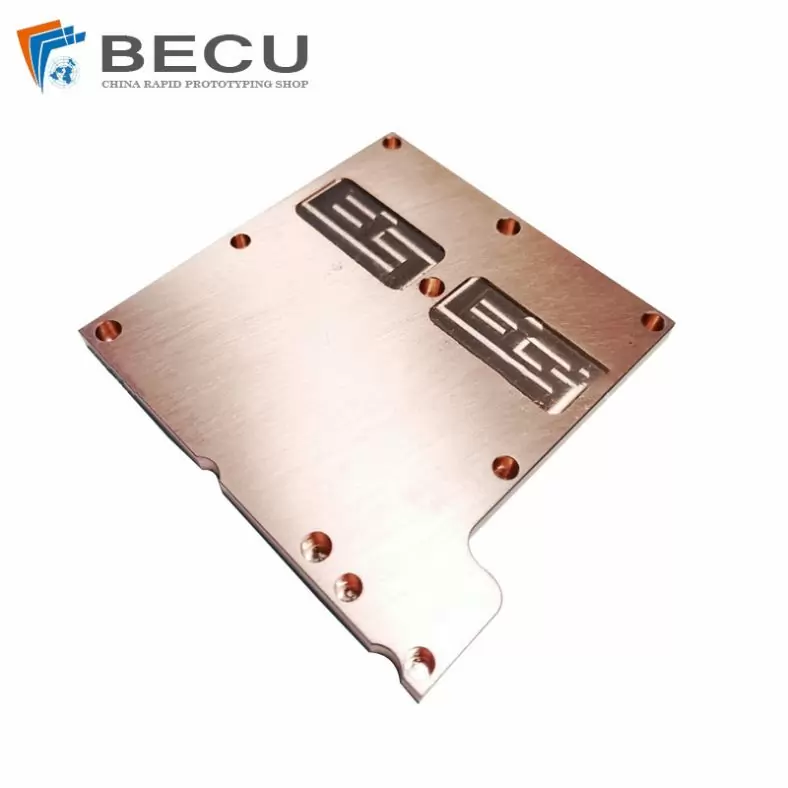

If you need copper parts cnc machined C17500 we are one of the most capable and affordable sources specializing in manufacturing custom machined parts on advanced 5 axis cnc machines with cnc precision. Be-cu Prototype is a complete cnc milling and cnc turning machine shop capable of machining Beryllium Copper C17500 parts to customer specification (conventional and 5 axis machining). With the support of advanced facilities and highly skilled experts, a series of CNC machining processes are available for making beryllium copper c17500 prototypes and batch production, including high-precision CNC milling, turning, 5-axis machining, wire EDM, and many more. Moreover, we also offer secondary processing options for machined copper parts to match mechanical and cosmetic purposes.We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files.

If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom beryllium copper c17500 machined parts.

Why Choose Our C17500 Cnc Machining Service?

- Save time and money for your beryllium copper C17500 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of copper grades and alloy materials can be machined

- Custom complex copper cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Beryllium Copper C17500 Machined Parts & Case Studies

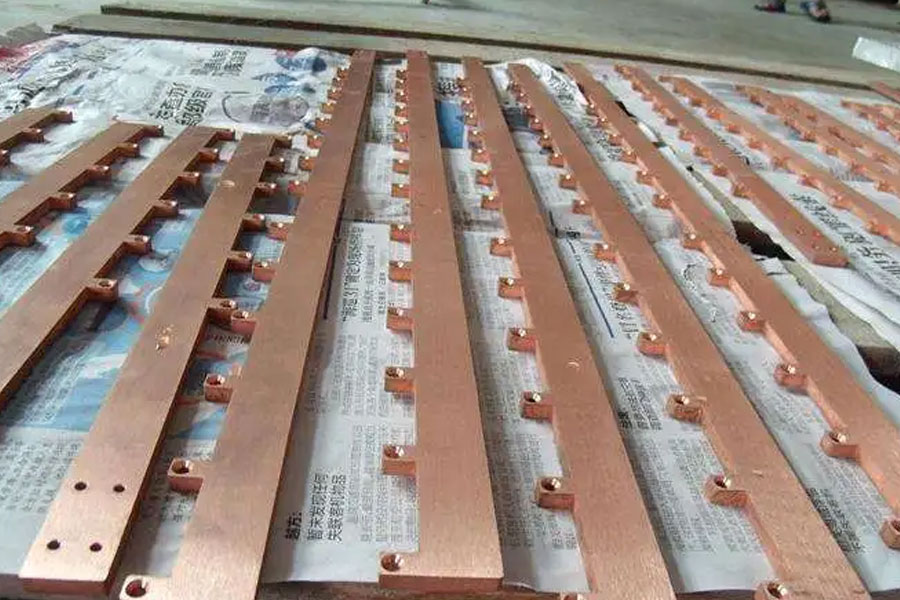

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make beryllium copper C17500 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal manufacturing is the only option. Our company has rich experience making beryllium copper concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on copper alloy. Be-cu prototyping company provides a range of solutions for the machining of copper parts.

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Precision Wire Cutting Plastic Injection Mould Core

-

Custom Machining Copper Water Cooling Heat Sink

-

Cnc Carved Machining And Wire Cutting Copper Electrode

-

CNC Milling Automotive Audio Amplifier Base

-

Precision Machining Heatsink Spacer Substrate

-

Precision Turning T3 Copper Machinery Parts By Polishing

-

Precision Milling Machining Chrome-Plated Copper Spare Parts

-

Precision CNC Turning N9 Copper Parts

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Precision Machined Copper Die Casting Parts

-

CNC Turning New Energy Vehicle Copper Connector

Online Cooperate With Beryllium Copper C17500 Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.