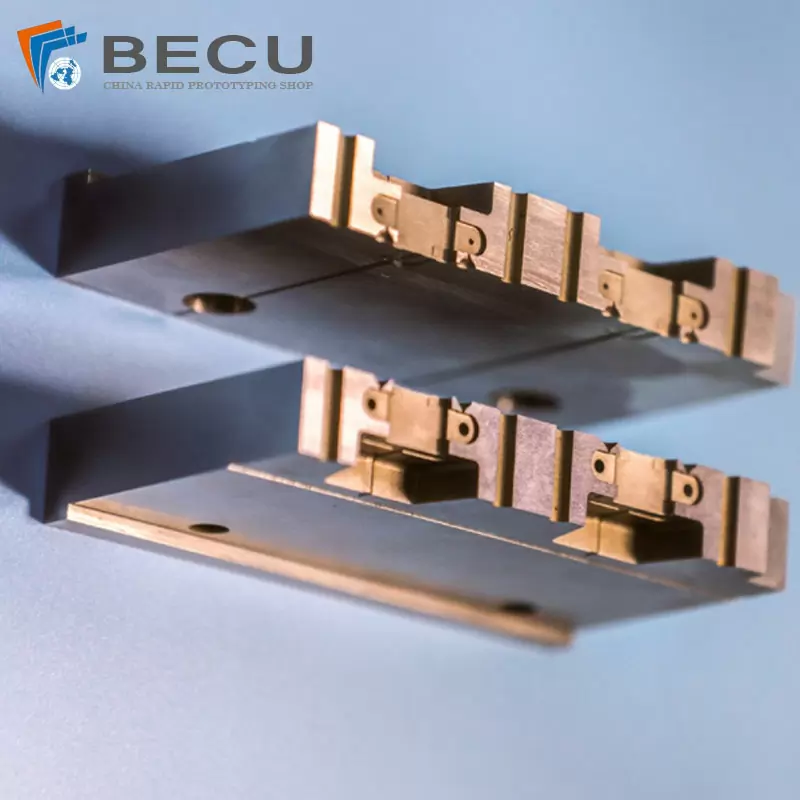

Plastic Injection Mould Core

- Product Name: Copper Mold Inserts

- No+Color:Custom

- Surface Treatment: Customized

- Product Material: Copper Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision CNC Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Mold Making

- Production Process: Wire Cutting

- Size: According To Customer’s Drawings

High-Quality Custom Precision Wire Cutting Plastic Injection Mould Core

Precision Wire Cutting services for Plastic Injection Mould Core. Capabilities include drawing, grinding, straightening and cutting. Capable of redrawing wire from 8 to 26 in. dia. and tolerance as close as +/-0.0002 in.

The Advantages Of Precision Wire Cutting Plastic Injection Mould Core

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Custom Precision Wire Cutting Plastic Injection Mould Core

| Material | Copper Alloy |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Wire Cutting,Laser Cutting |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Plastic Injection Mould Core |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Wire Cutting Company

BE-CU is a specialist that can fabricate industrial parts and custom machined parts using a wide variety of manufacturing techniques. With Wire Cutting Services at be-cu.com, you can get your wire EDM parts in a much more accurate and fast way, compared to conventional machining. Our newest wire cutting machines can meet your needs of high volume while maintaining high repeatability, top quality and tight tolerance. Over the past years, we have earned a good reputation for producing custom parts with reasonable pricing and on-time delivery, and also capable of working with electrical discharge machining equipment to provide wire cut EDM parts and services for our customers. Our EDM services offer experience and excellence in all types of EDM machining, welcome to submit an inquiry online.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles