What Is CNC Fixtures & Clamping

Computer Numerical Control (CNC) machining is a fundamental aspect of modern manufacturing, enabling the production of highly precise and complex components with high efficiency. A critical part of the CNC machining process is the use of fixtures and clamping systems.

Clamping systems are mechanisms used to apply force to a workpiece to hold it in place against the fixture during machining. They are critical for maintaining the stability and integrity of the workpiece under the forces exerted during machining operations.

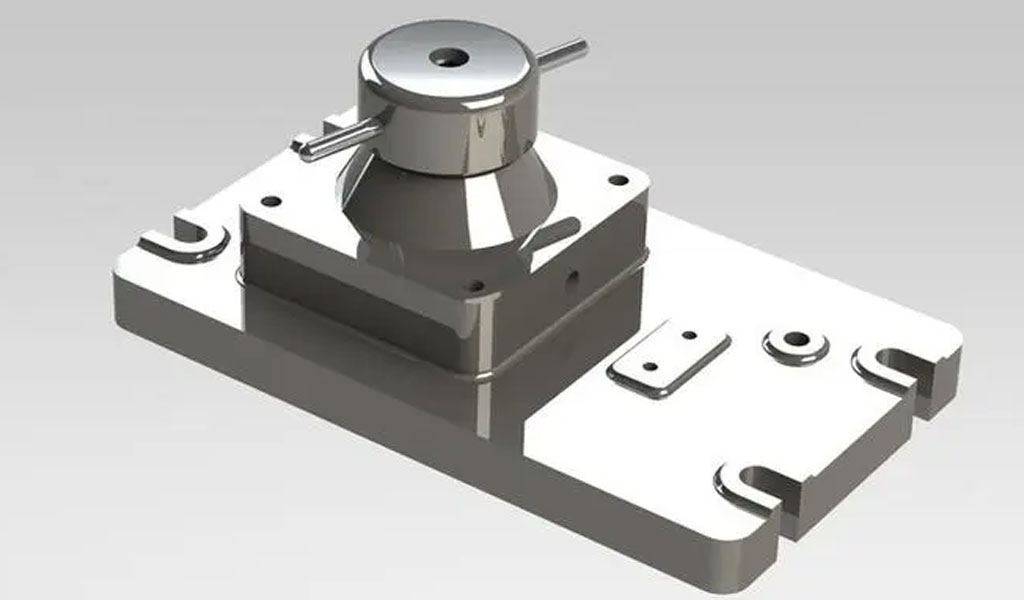

These tools are essential for securing and stabilizing workpieces during machining operations, ensuring accuracy, repeatability, and safety.CNC fixtures are devices designed to hold a workpiece securely in place during the machining process.Their primary function is to ensure that the workpiece is consistently positioned accurately, allowing for precise and repeatable machining operations.Fixtures can range from simple mechanical clamps to complex automated systems that integrate with CNC machinery.

CNC Machining Fixture And Clamping Systems Tooling Manufacturer

The proper clamping of workpieces holds paramount importance in machining operations, whether employing conventional methods or CNC machines. BE-CU, a distinguished manufacturer of CNC parts and tooling, excels in crafting CNC fixtures and clamping systems for diverse applications.

Fixtures can be fabricated to custom sizes and shapes. Available in 72 in. length and 42 in. width with close tolerance.Works with 6061 aluminum, P-20, H-13, 4150, titanium and Inconel®. Provides 3D solid models for approval prior to build and CMM certifications of critical dimensions.From VMC machining fixtures to vacuum fixtures and mechanical jigs, place your trust in the seasoned experts and engineers at BE-CU. We are dedicated to fixture design and machining, as well as other tooling manufacturing, striving to minimize downtime costs and enhance efficiency. This ensures a cost-effective solution with a swift turnaround. Quickly upload your CAD files or send us your inquiry to receive a prompt response online.

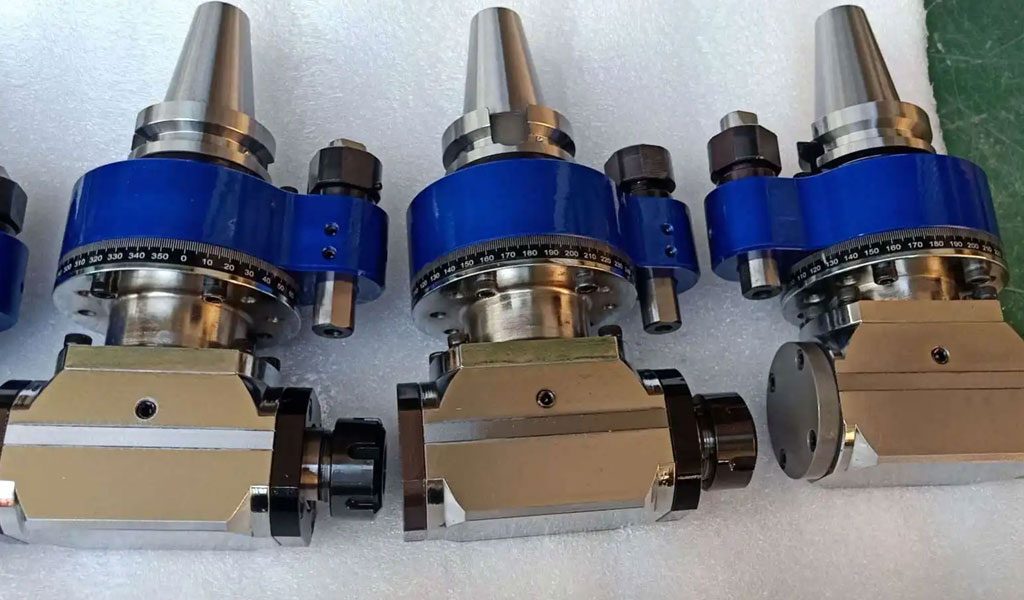

CNC Milling Fixtures

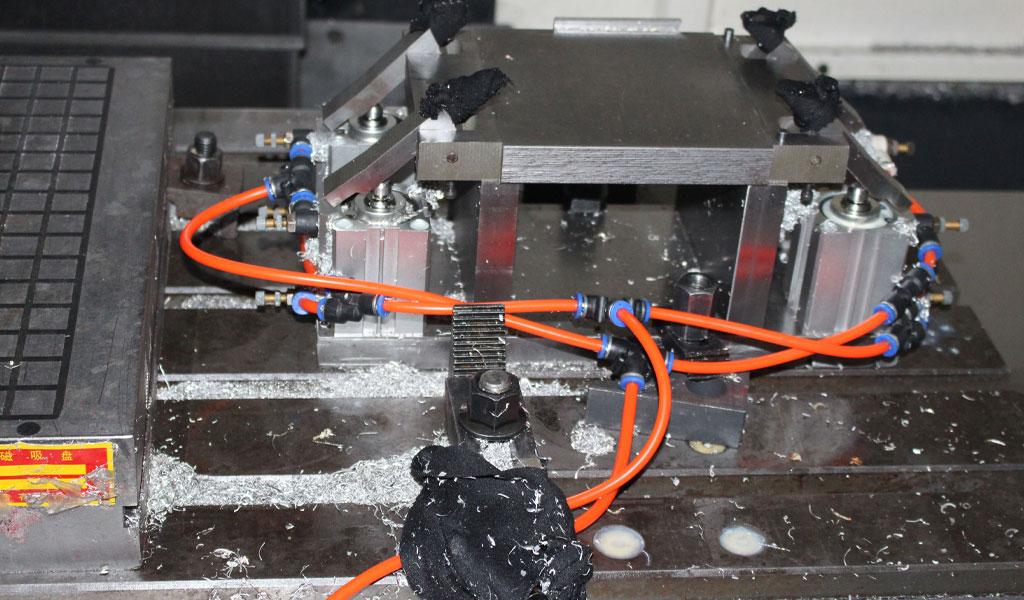

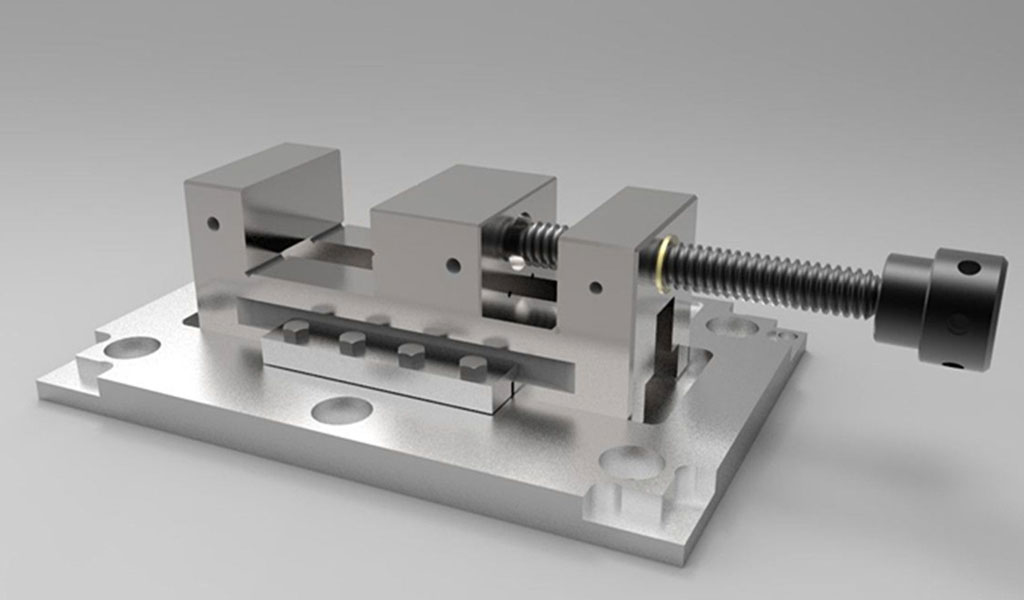

CNC milling fixtures are devices used in CNC (Computer Numerical Control) milling machines to hold, support, and position a workpiece securely during the machining process. In this manufacturing process, rotary table fixtures, vise fixtures, fixture plates, T-slot, and indexing fixtures are common types of CNC milling fixtures.These fixtures ensure precision, repeatability, and stability, enabling efficient and accurate manufacturing of parts.

CNC Turning Fixtures

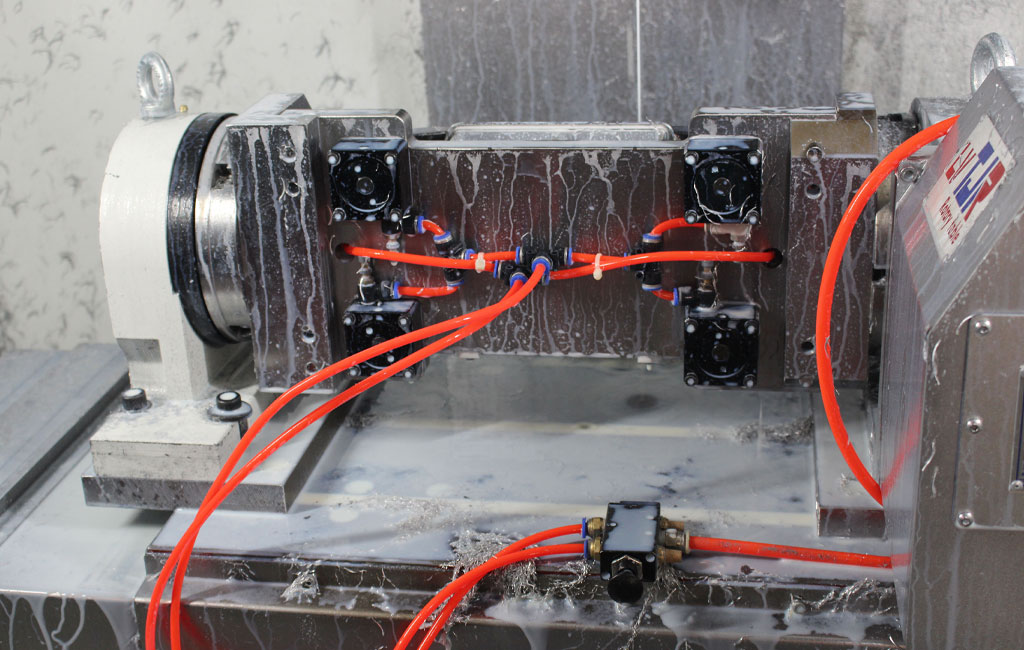

CNC turning fixtures are devices used to hold, support, and locate a workpiece securely during CNC (Computer Numerical Control) turning operations. Common examples of turning fixtures include faceplate, collet, chuck, and mandrel fixtures.These fixtures ensure that the workpiece is positioned accurately and remains stable throughout the turning process, which is essential for achieving precision and repeatability in the production of cylindrical parts.

Wire EDM Fixtures

Wire EDM (Electrical Discharge Machining) fixtures are essential devices used to hold, support, and position a workpiece securely during the wire EDM process. Common examples of BE-CU’s Wire EDM fixtures include Base Plate,Clamping Elements,Locating Pins and Bushings,Support Elements and more.This machining technique uses a thin, electrically charged wire to cut through metal, allowing for high-precision and complex shapes.

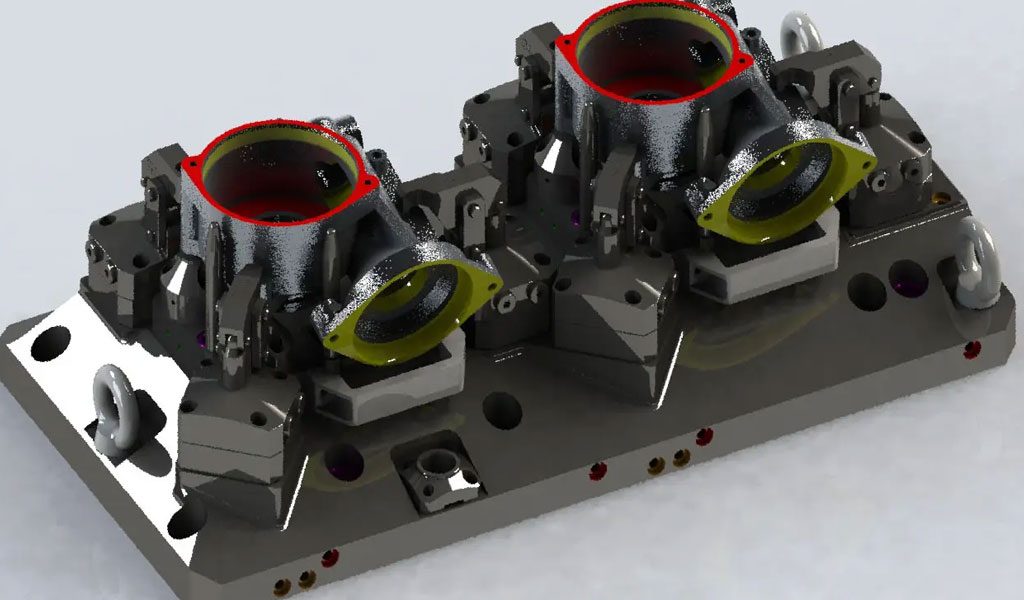

Check Fixture Components

Check fixtures, also known as inspection fixtures, are tools used to verify the accuracy and quality of manufactured parts. They ensure that parts conform to specified dimensions, geometries, and tolerances. In this manufacturing process, Base Plate, Bushings, Locating Pins,V-Blocks, Clamping Elements(Including Manual Clamps,Pneumatic/Hydraulic Clamps,Toggle Clamps),Inspection Gauges,Support Elementsand indexing fixtures are common types of CNC milling fixtures.

Why Choose BE-CU CNC Fixtures

In the course of many years, our extensive experience and profound knowledge empower us to navigate through various levels of complexity with adeptness. Our expertise encompasses the manufacture of CNC fixtures, assembly tooling, and specialized machinery, among other capabilities. From the inception of an idea to the delivery of the final product, we offer bespoke fixtures tailored to meet the needs of any industry. Our unwavering commitment to safety and quality ensures that rigorous inspections are an integral part of our process. We pride ourselves on offering reasonable prices that align with your specifications, quality standards, and budgetary constraints.

Examples of BE-CU’ CNC Fixtures Machining Capabilities

BE-CU is the top choice for CNC Fixtures Machining, known for its unmatched commitment to quality and precision. Achieving in six months what takes others 3 years, BE-CU excels in producing flawless components for critical industries like fixtures. Utilizing high-quality materials and advanced CNC machinery operated by computer programs, BE-CU eliminates human errors, delivering consistently accurate results.

Angle Fixtures

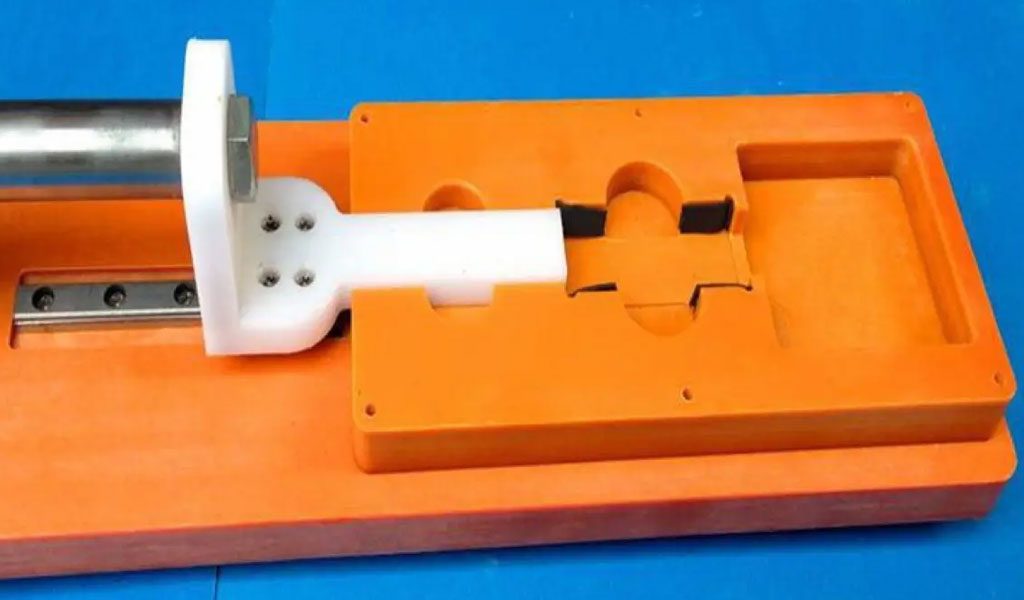

Bakelite Clamp Fixtures

CNC Vise Fixtures

Jig Fixtures

Modular Fixtures

Universal Clamp

Our Case Studies Gallery Of Machining Fixture And Components

Put Be-cu.com’ experience to work for all of your machining fixture and mold parts and components needs —from cnc mill fixtures to precision check fixture components . Are you looking for machining fixture manufacturers in China? Contact us to get started on your journey with a Chinese machining fixture manufacturer. Let us be your OEM and machining fixture company in China. Send us an email to get a price now.