Wear-Resistant HDPE Fasteners

- Product Name: HDPE Parts

- No+Color: Black

- Surface Treatment: Custom

- Product Material: Plastic

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Turning

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Machinery Parts

- Process: Cnc Machining HDPE Plastic

- Size: According To Customer’s Drawings

High-Quality CNC Turning Wear-Resistant HDPE Fasteners

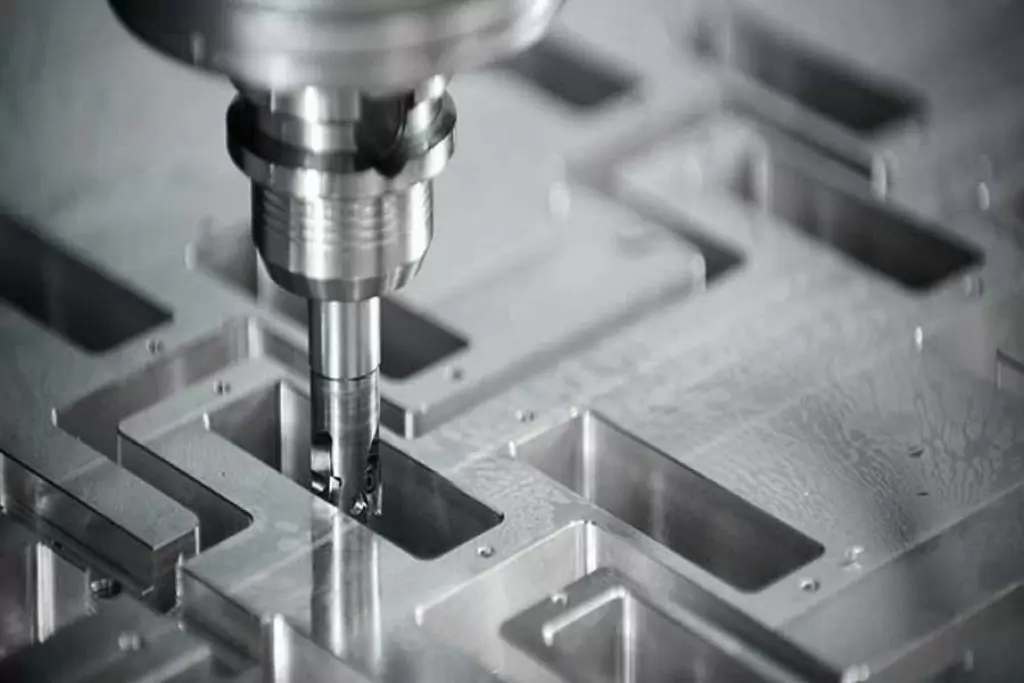

In the world of precision engineering, where strength, resilience, and precision matter most, our CNC Turning Wear-Resistant HDPE Fasteners emerge as the solution of choice. Designed to redefine standards, these fasteners seamlessly combine advanced CNC turning technology with the exceptional properties of High-Density Polyethylene (HDPE) to create a new era of dependable connections.

- Unyielding Durability:Crafted through CNC turning, a process renowned for its accuracy and precision, our fasteners are forged to withstand the test of time. Enhanced with the remarkable wear-resistant attributes of HDPE, these fasteners offer unparalleled longevity, even when faced with challenging operating conditions.

- Mastering Environmental Challenges:Boasting resilience that goes beyond convention, our fasteners are engineered to conquer environmental challenges. The HDPE material resists moisture, chemicals, and corrosive substances, ensuring your connections remain steadfast in even the most demanding settings. Whether exposed to the elements or harsh chemicals, these fasteners hold their ground with unwavering strength.

- Seamless Integration:The CNC turning process ensures that each fastener is precision-crafted to exact specifications, allowing for smooth integration into any project. Achieving a flawless fit becomes effortless, enhancing the overall performance of your assemblies. The fasteners’ uniformity and precision contribute to a secure and reliable connection every time.

- Versatile Applications:From mechanical assemblies to industrial equipment, our CNC Turning Wear-Resistant HDPE Fasteners find their place in diverse applications. Whether you’re constructing a rugged outdoor structure or assembling intricate machinery, these fasteners offer a dependable solution for a wide range of projects.

- Elevating Aesthetics and Functionality:Our fasteners don’t just excel in function; they also exhibit a refined aesthetic. The inherent properties of HDPE allow for a consistent, clean appearance that complements the visual appeal of your creations. Your projects benefit not only from their mechanical strength but also from the sophistication they bring to every connection.

- A Commitment to Excellence:Rooted in innovation and precision engineering, our CNC Turning Wear-Resistant HDPE Fasteners embody a commitment to excellence. Each fastener is a testament to our dedication to providing solutions that empower your projects with enduring performance and unmatched reliability.

Incorporate the future of connections into your projects with our CNC Turning Wear-Resistant HDPE Fasteners. Set the standard for durability, precision, and longevity, and experience connections that transcend expectations.

Choose reliability. Choose innovation. Choose our CNC Turning Wear-Resistant HDPE Fasteners and secure connections that withstand the challenges of time and environment. Your projects deserve nothing less.

The Advantages Of CNC Turning Wear-Resistant HDPE Fasteners

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of CNC Turning Wear-Resistant HDPE Fasteners

| Material | HDPE |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

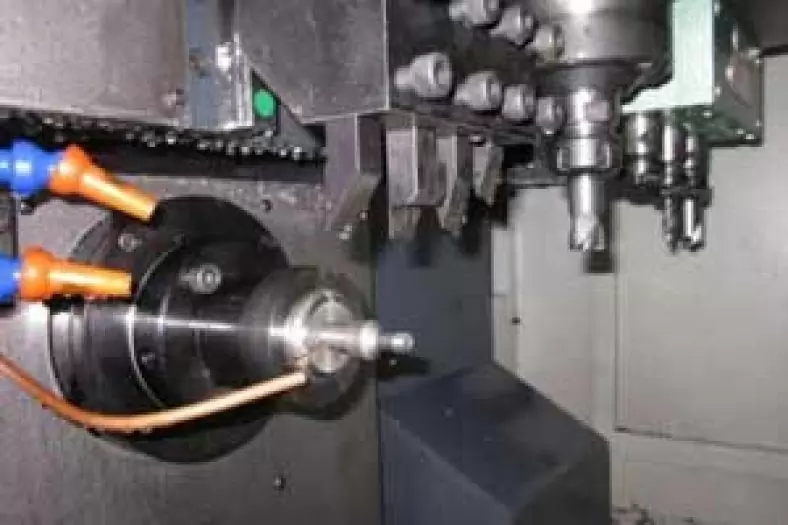

| Main Process | CNC Milling, Swiss Machining, 5 Axis Cnc Machining , CNC Turning |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machinery Parts |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]