What Is Robotic Machining

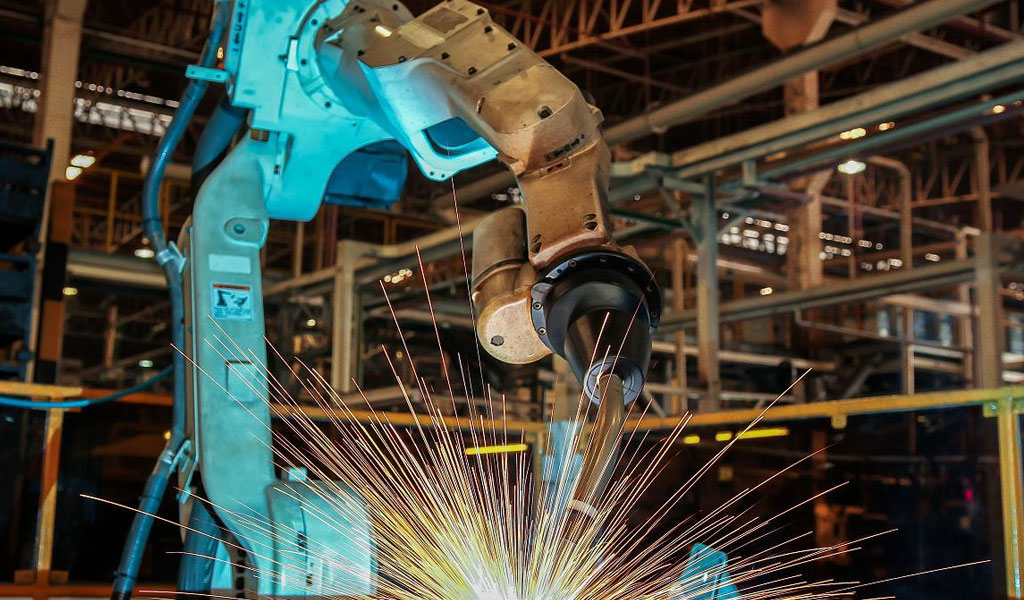

In the realm of modern manufacturing and automation, robotics has emerged as a pivotal technology that drives efficiency, precision, and productivity. At the core of any robotic system lies the intricate and critical task of machining robotic parts. These components serve as the backbone of robots, dictating their performance, accuracy, and overall functionality.Robotic parts are the building blocks that give form and function to robotic systems. These components include but are not limited to joints, actuators, sensors, frames, and connectors machining. The design and manufacturing of these parts play a pivotal role in determining the robot’s capabilities, range of motion, payload capacity, and overall lifespan.

Computer Numerical Control (CNC) machining stands as a cornerstone in the production of robotic parts. This subtractive manufacturing process involves the utilization of pre-programmed computer software to control the movement of machinery tools. CNC machining ensures unparalleled precision, enabling manufacturers to create complex geometric shapes with tight tolerances. Milling, turning, and drilling are some of the primary CNC machining processes employed in crafting robotic parts.

Robotic Machining Service – Custom CNC Robotic Machining Parts

As industries continue to advance and seek higher levels of efficiency and precision, the demand for impeccable robotic parts and components has never been greater. Our Robotic Machining service has been meticulously developed to address this demand by combining state-of-the-art technology with our decades of expertise in manufacturing and automation.At Be-Cu, we offer several CNC Machining capabilities, including three, four, and five-axis machining. We also offer a broad range of materials, such as aluminum alloys, steel, titanium, plastics, and more. Leveraging our CNC Machining expertise and vast manufacturing network, we can deliver robotic parts and components in as little as three days for our customers.

Our manufacturing network and in-house equipment allow us to fulfill all manner of part orders, from single-run prototypes to large volume manufacturing. Since the robotic industry is a high-risk industry, we recognize the importance of precision and quality control when making robotic parts.For the most critical parts in your inventory, we can accommodate extra-fine tolerances, down to +/-0.01 mm. This gives you the ability to build complex interlocking systems with a tight fit.We also guarantee quality via several quality control techniques. Technical assessments are carried out prior to manufacturing to identify potential design flaws, and material verification is available on request. This helps to confirm material heat number, grade, dimensions, and other specifications.

We fit our CNC machines with on-machine inspection probes, and we observe in-process quality control and first-article inspection (on request). A full dimensional inspection report is also available on request. All of these come at competitive prices

Prototyping Applications of CNC Machining for Robotic Industry

CNC Machining allows for the precise and automated production of complex parts and components, making it an ideal method for prototyping and producing various robotic applications. CNC machining allows for rapid prototyping of different robot components. Engineers can quickly create and test iterations of parts, refining designs before moving to full-scale production. This iterative process can significantly speed up the development timeline.Here are some prototyping applications of CNC machining in the robotic industry:

Robot Frames and Structural Components

Joints and Articulations

End Effectors and Grippers

Sensor Housings and Mounts

Covers and Enclosures

Cable Management and Routing

Custom Brackets and Mounts

Educational and Research Robots

Collaborative Robot Components

Aerospace and Defense Robots

Why Choose Our Robotic Parts Machining Service?

- Save time and money for your robotic project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex robotic parts machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for LED customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Cnc Robotic Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more robotic manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the robotic industry, the application of CNC Machining in die casting robotic parts, how CNC Machining changes the robotic manufacturing supply chain, and more.