Cnc Machining 316 Stainless Steel

316 stainless steel is a widely used stainless steel alloy that belongs to the austenitic family of stainless steels. It is composed of iron, chromium, nickel, molybdenum, and small amounts of other elements. The specific composition of 316 stainless steel is as follows:

The Composition Of 304 Stainless Steel

- Iron (Fe): Balance (approximately 62-69%)

- Chromium (Cr): 16-18%

- Nickel (Ni): 10-14%

- Molybdenum (Mo): 2-3%

- Carbon (C): Maximum 0.08%

- Manganese (Mn): Maximum 2%

- Silicon (Si): Maximum 0.75%

- Phosphorus (P): Maximum 0.045%

- Sulfur (S): Maximum 0.03%

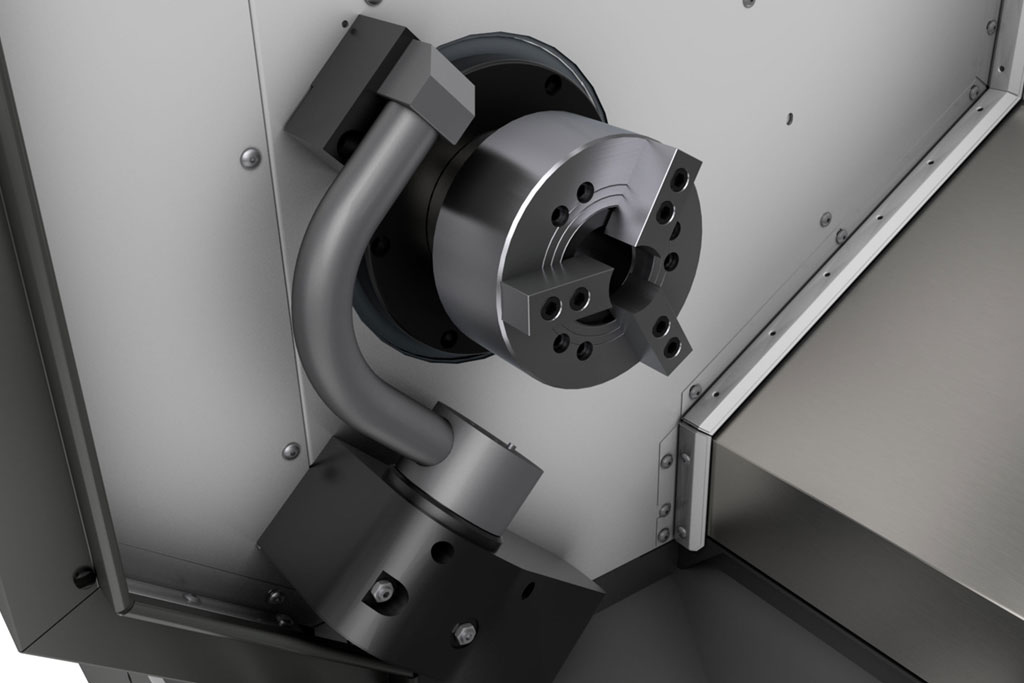

CNC machining of 316 stainless steel involves using computer-controlled machines to remove material from a workpiece made of this specific stainless steel alloy. The process follows the principles of CNC (Computer Numerical Control) machining, where the machine’s movements are precisely controlled by computer programs to achieve the desired shape and dimensions. CNC machining techniques like milling, turning, drilling, and threading can be applied to 316 stainless steel. These processes involve removing material from the workpiece to create the desired shape, features, and dimensions. CNC machines can perform these operations accurately and efficiently.

Benefits Of 316 Stainless Steel Machining

CNC machining of 316 stainless steel offers several benefits, including:

- Precision and repeatability in achieving tight tolerances and complex geometries.

- Ability to produce high-quality surface finishes on the machined components.

- Versatility to create various parts and components for industries such as aerospace, automotive, medical, and more.

- Efficient production with reduced labor costs and increased productivity through automation.

CNC machining is a reliable and effective method for machining 316 stainless steel, allowing for the creation of precise and high-quality components that meet the requirements of different applications.

Cnc Machining 316 Stainless Steel Services

CNC machine setups can significantly impact your overall production costs, but sometimes using multiple CNC setups can’t be helped. The good news is that you can make your project more cost-effective — even if multiple setups are required — by setting reasonable tolerances, designing for manufacturability, and thoughtfully choosing 316 stainless steel alloy. Working with an experienced manufacturing partner like Be-Cu prototype can help.

Get started on your next CNC machining 316 stainless steel project today by uploading your part to be-cu.com for an instant quote or by contacting our team.

Industries & Applications

316 is a free-cutting stainless steel containing sulfur and selenium respectively, and is used in occasions where easy cutting and high surface finish are mainly required. 303 stainless steel improves cutting performance and high temperature bonding performance.

- Bolts and nuts

- Gears

- Screws

- Shafts

- Marine Parts

- Connectors

- Terminals

- Aircraft components

316 Stainless Steel Machining Capabilities

- Swiss Machining 316 Stainless Steel

- CNC Milling 316 Stainless Steel

- CNC Turning 316 Stainless Steel

- 5 Axis Machining 316 Stainless Steel

- CNC Cutting 316 Stainless Steel

- Turn-Mill Machining 316 Stainless Steel

- More

You can contact us by requesting a quote for any 316 Stainless Steel manufacturing process. One of our project managers will review your application and get a quote and DFM feedback for you within 12 business hours.

Why Choose Our 316 Stainless Steel Cnc Machining Service?

- Save time and money for your 303 Stainless Steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of stainless steel grades and alloy materials can be machined

- Custom complex stainless steel cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Stainless Steel Alloy 316 Machined Parts

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make 316 Stainless Steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes laser cutting is the only option. Our company has rich experience making 316 Stainless Steel concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on stainless steel alloy. Be-cu prototyping company provides a range of solutions for the machining of Stainless Steel parts.

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Turning Stainless Steel 316 Grinding Core For Coffee Mill

-

Precision 316 Stainless Steel Cookware Boiler Cover For Kitchen

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

CNC Turning 24K Gold-Plated Beauty Instrument Massage Head

-

CNC Turning Diamond Dermabrasion Head Microdermabrasion Replacements Tips

-

CNC Turning Stainless Steel 316 Men Spinner Rings

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Precision CNC Turning Stainless Steel Transmission Arm Parts

-

Precision Cnc Turning Stainless Steel 316 Machine Screw

Mechanical Properties Of Stainless Steel Alloy 316

The mechanical properties of stainless steel alloy 316 are as follows:

- Tensile Strength: The tensile strength of stainless steel 316 is typically around 515 MPa (75,000 psi). This indicates the maximum amount of tensile stress the material can withstand before it fails or fractures.

- Yield Strength: The yield strength of stainless steel 316 is usually around 205 MPa (30,000 psi). This is the stress at which the material exhibits permanent deformation or begins to yield under tensile loading.

- Elongation: Stainless steel 316 typically exhibits an elongation of approximately 40%. Elongation is the measure of the material’s ability to stretch or deform without fracturing and is expressed as a percentage of the original length.

- Modulus of Elasticity: The modulus of elasticity, or Young’s modulus, of stainless steel 316 is about 200 GPa (29.0 x 10^6 psi). This property defines the material’s stiffness or resistance to elastic deformation under applied stress.

- Hardness: Stainless steel 316 typically has a hardness value of around 95 HRB (Rockwell B Hardness). Hardness measures the material’s resistance to indentation or scratching and can vary depending on the specific heat treatment and processing conditions.

- Impact Resistance: Stainless steel 316 exhibits good impact resistance, allowing it to absorb energy and resist fracture or failure under impact or sudden loading conditions.

Online Cooperate With Stainless Steel Alloy 316 Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.