What Is Ti 6Al-4V (Grade 5)

Ti 6Al-4V, also known as Grade 5 titanium, is a two-phase α+β titanium alloy, which combines the desirable properties of both phases.

The alloy exhibits high tensile strength, lightweight, and good fatigue resistance, which are essential for applications where failure is not an option. The addition of aluminum and vanadium enhances the alloy’s strength and thermal stability, making it suitable for high-performance components.

Titanium alloys are prized for their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These characteristics make them ideal for critical applications in aerospace, medical devices, automotive components, marine environments, and the energy sector. Ti 6Al-4V, in particular, is renowned for its excellent balance of strength, toughness, and workability, which is why it is the preferred choice in demanding engineering applications.

Ti 6al 4v Machinability

Material Properties

- Hardness and Strength: Ti 6Al-4V has high hardness and tensile strength, making it resistant to deformation but challenging to cut.

- Low Thermal Conductivity: Titanium alloys, including Ti 6Al-4V, have low thermal conductivity, causing heat to concentrate at the cutting zone, which can lead to tool wear and workpiece damage.

- Elastic Modulus: The relatively low elastic modulus of Ti 6Al-4V can cause chatter and deflection during machining.

Work Hardening

Physical Properties

Ti 6Al-4V exhibits unique physical properties that contribute to its widespread use:

- Density: 4.43 g/cm³, which is about 60% of the density of steel, making it an ideal material where weight savings are crucial.

- Melting Point: 1660-1670°C, which allows it to retain strength at high temperatures.

Chemical Reactivity

Chemical Composition

The chemical composition of Ti 6Al-4V is a critical factor in its performance. The alloy consists of approximately:

- Titanium (Ti): Balance

- Aluminum (Al): 6%

- Vanadium (V): 4%

- Iron (Fe): ≤ 0.25%

- Oxygen (O): ≤ 0.2%

This specific composition imparts the alloy with its distinctive properties, such as high strength, lightweight, and resistance to corrosion and high temperatures.

Mechanical Properties

The mechanical properties of Ti 6Al-4V are highly favorable for high-stress environments:

- Tensile Strength: Typically ranges from 895 to 930 MPa.

- Yield Strength: Approximately 880 MPa.

- Elongation: About 10-15%, providing good ductility.

- Hardness: Typically around 36 HRC.

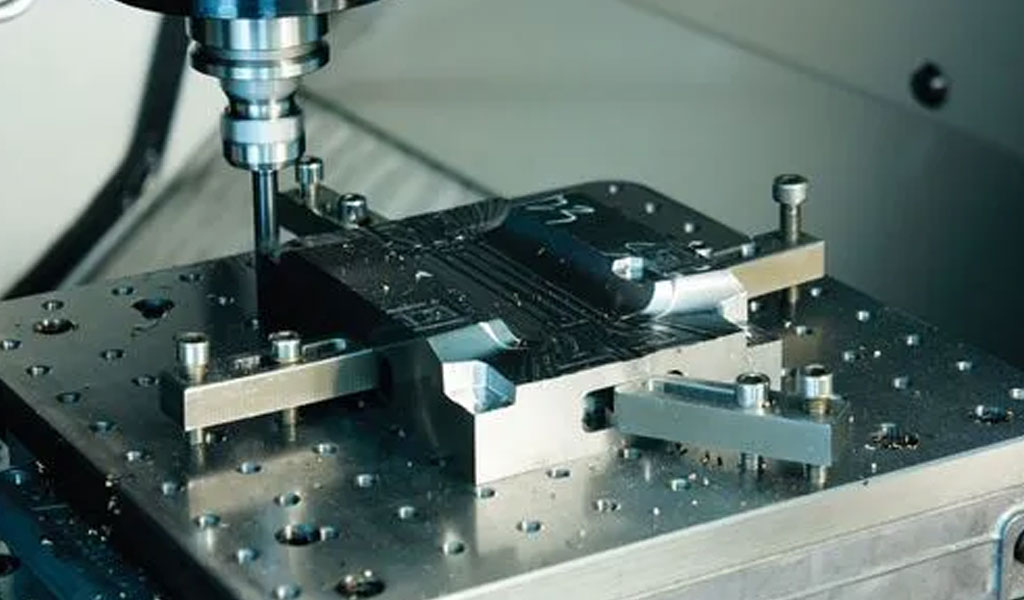

CNC Machining Ti 6Al-4V (Grade 5) – TC4 Machining

We use a computer-assisted cnc machine to machining Ti 6Al-4V titanium, which makes our services very versatile. We can cnc machining any object of any size, regardless of the detail of the machining. We can provide you with beautifully and permanently marked titanium objects for almost any recipient or purpose.

At Be-Cu prototype, we pride ourselves on offering a wide range of services, including:

- Ti 6Al-4V CNC Milling

- Ti 6Al-4V CNC Turning

- Ti 6Al-4V Grinding

- Ti 6Al-4V Surface Treatment

- EDM And Wire EDM

If you are interested in learning more about our Ti 6Al-4V CNC Machining services, please do not hesitate to contact our cnc machining workshop. We would be more than happy to discuss your project requirements and provide you with a competitive quote.

Why Choose Our Ti 6Al-4V Cnc Machining Service?

- Save time and money for your Ti 6Al-4V project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of titanium grades and alloy materials can be machined

- Custom complex Ti 6Al-4V cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

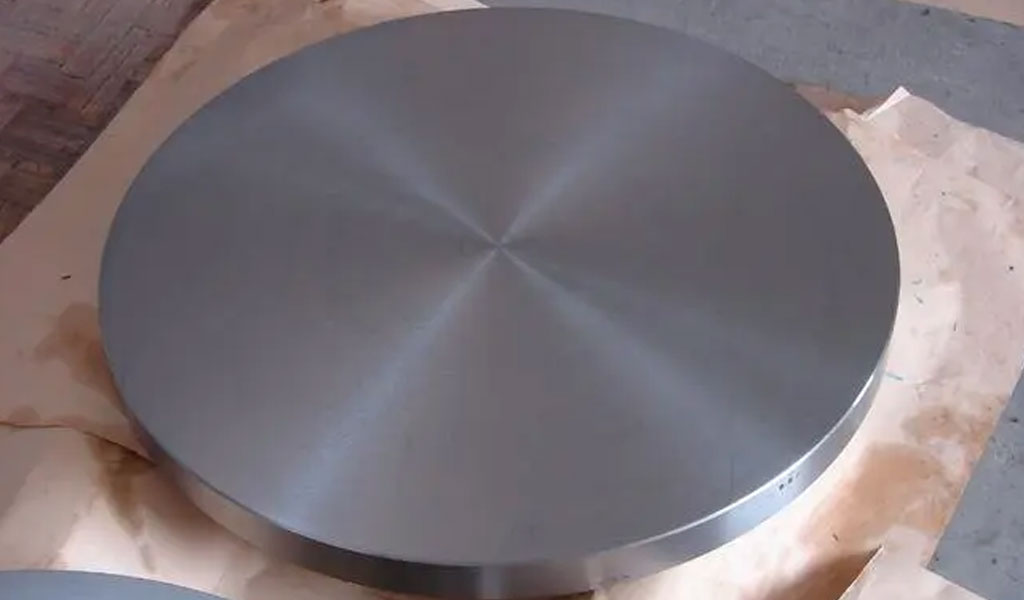

Ti 6Al-4V (Grade 5) Machined Parts

Cnc Machining processes such as cnc milling, turning and EDM machining are today considered the most economic way to make CNC Ti 6Al-4V prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes laser cutting is the only option. Our company has rich experience making Ti 6Al-4V concept models and precise functional components. Understanding the properties of different steel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the machining of titanium parts.

-

5 Axis CNC Machining Medical Olecranon Plate

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Deep Hole CNC Turning Titanium Alloy Dispensing Needle

-

Precision Turning TC4 Alloy Medical Ultrasound Bead Needle

-

5 Axis Machining Optical Communication Parts And Telecom Parts

-

Titanium Alloy Internal Fixation Plate For Medical Equipment

-

Medical Sensor Power Supply Housing

-

5 Axis Cnc Machining Titanium Motorcycle Frame