Cnc Milling Carbon Fiber Service In China

As one professional Cnc Milling services manufacturers in China, BE-CU can machine all kinds of low cost carbon fiber materials parts. One of the most popular engineering material – carbon fiber CNC Milling part will not be ignored. Be-cu customizes precision CNC carbon fiber parts according to customer specifications, samples or drawings. Our CNC Milling carbon fiber precision parts can undertake surface spraying, electroplating, metal welding, hot pressing and adhesion, widely used in machinery, automobile, electronic appliances, instruments and meters, textile and construction industries. Cnc Milling services for carbon fiber materials. Capable of fabricating parts up to 4 in. thickness with +/- 0.003 in. tolerance. Other capabilities include boring, drilling, knurling, milling, turning, tapping and threading. Design, prototyping and drafting services are also offered. Prototype to low and high volume production. Suitable for advertising, architecture, appliance, machinery, retail, packaging, restaurant, railroad, power generation and heavy equipment applications.

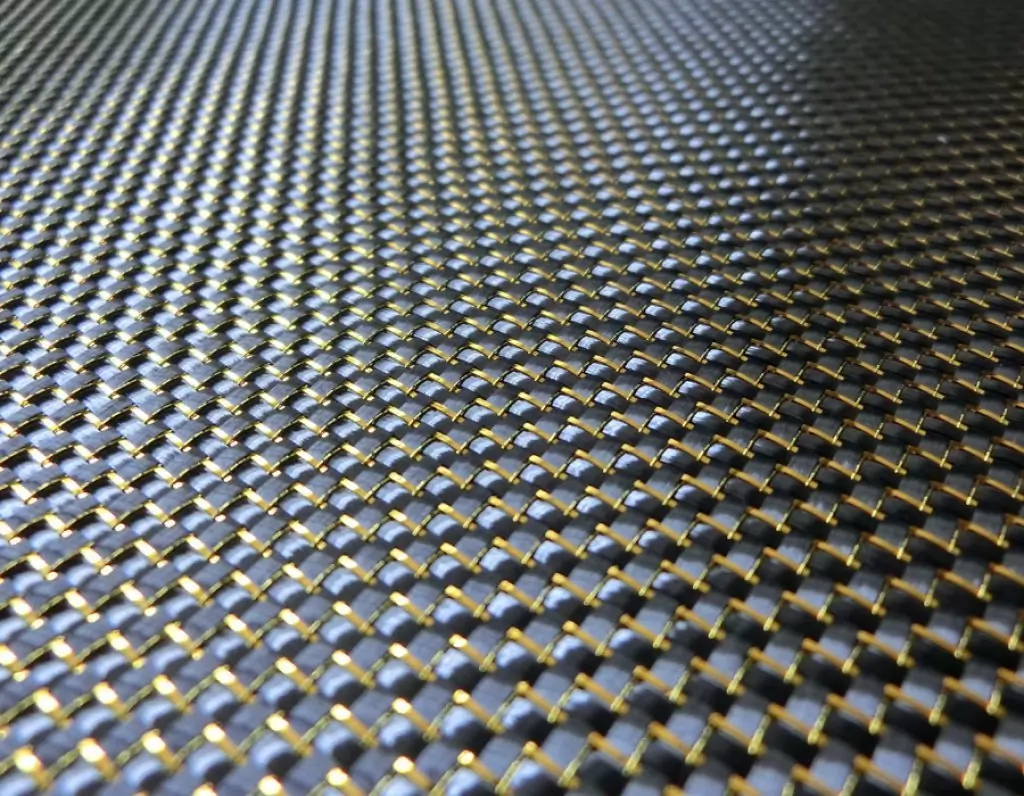

Cnc Milling is usually used for the processing of carbon fiber products with high precision and complex shapes. In a sense, milling can be regarded as a correction operation because milling can obtain a higher quality machined surface. During the machining process, due to the complex interaction between the end mill and the carbon fiber composite material, the phenomenon of delamination of the carbon fiber composite material workpiece and uncut fiber yarn burrs occur from time to time. In order to reduce the phenomenon of fiber layer delamination and burrs, we have gone through a lot of attempts and explorations.

In the process of machining, accurate prediction of thrust force and axial cutting force can avoid the occurrence of fiber delamination and burr. Reasonable design and control of the tool path can also effectively prevent burr formation and fiber delamination. The main process parameters, such as fiber orientation, axial and tangential feed rates, cutting speeds, etc., have a significant impact on the surface roughness of carbon fiber workpieces.

The Advantage Of Cnc Milling Carbon Fiber

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient CNC machining factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding Cnc Milling Carbon Fiber Equipment

- CNC Swiss Turn by Tsugami

- MAZAK 5 Axis Turn-Mill Machine

- CNC Swiss Turn by Tsugami

- High Speed Drilling-Tapping Machine

- DMU 5 Axis Cnc Machine

- CNC Mill Turn Centers—12 machines

- Multi Spindle Cam Automatics

- CNC Brother Production Milling

- Check Out BE-CU Equipment List