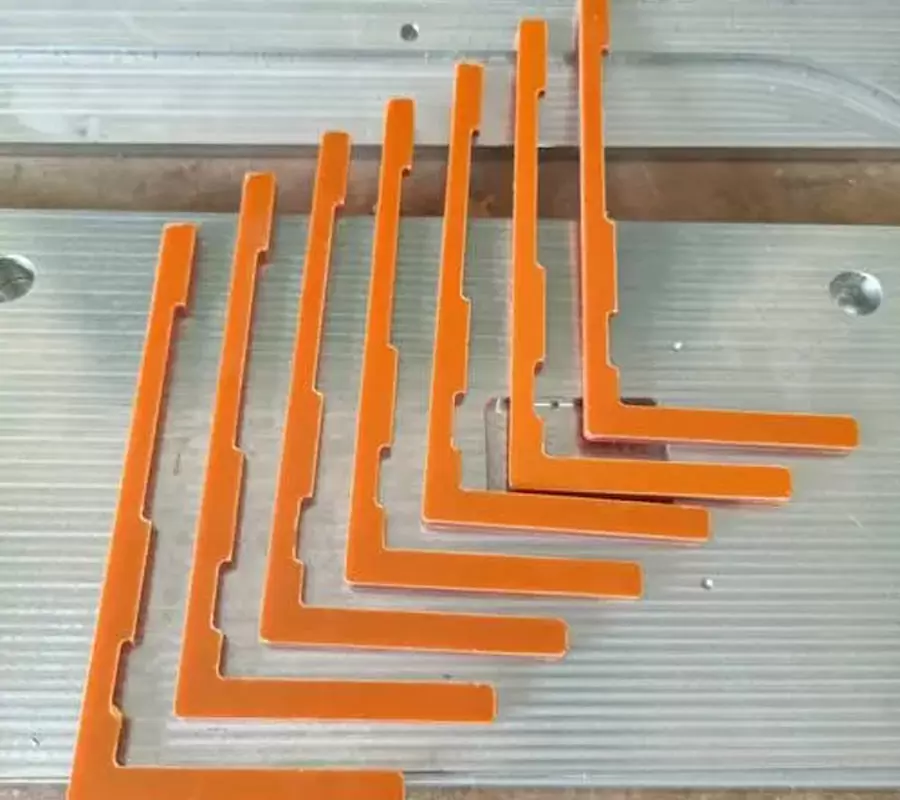

Mask Machine Bakelite Baffle

- Product Name: Bakelite Parts

- No+Color:Custom

- Surface Treatment: Oxidation

- Product Material: Plastic

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Machinery

- Process: Cnc Machining Bakelite

- Size: According To Customer’s Drawings

High-Quality Precision Milling Mask Machine Bakelite Baffle

Precision milling typically involves using specialized machines to remove material from a workpiece with high accuracy and tight tolerances. A “Bakelite baffle” could refer to a part made from Bakelite, which is a type of plastic known for its electrical insulating properties and heat resistance. This baffle might be used in the precision milling process to guide or control the movement of the workpiece or to protect certain components from milling debris.

The Advantages Of Precision Milling Mask Machine Bakelite Baffle

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Precision Milling Mask Machine Bakelite Baffle

| Material | Bakelite |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | CNC Milling, Swiss Machining, 5 Axis Cnc Machining , CNC Turning |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Jig And Fixture |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

Bakelite(CNC Machining Bakelite Plastic Jig and Fixtures) is a synthetic chemical material. Once heated and formed, it cannot be remade into other things. With excellent performance in hydrophobicity, electrical insulation, abrasive resistance, high strength and thermal resistance, it is used widely in electronic appliance. CNC machining bakelite jigs and fixtures are also common in production line of electronic products.

CNC machining bakelite jigs and fixtures are suitable for insulating parts of mechanical equipment. Besides, they are also common in PCBA drilling mat, distribution box, fixture board, high-voltage or low-voltage marshalling box, packing machine and comb. The machining methods of bakelite are various, like numerical-controlled engraving, numerical-controlled drilling and CNC machining. After studying the design drawing, we can decide which method is the best for you.With over 30 years of engineering expertise we are dedicated to offering the highest quality Bakelite CNC machining and other products.For your custom Bakelite CNC machining design, or fixtures engineering, our exemplary service and efficient production ensures prompt deliveries coupled with outstanding service.