What Is Contract CNC Machining

Contract CNC machining refers to the practice of outsourcing the manufacturing of precision machined components or parts to specialized companies that possess Computer Numerical Control (CNC) machining capabilities.

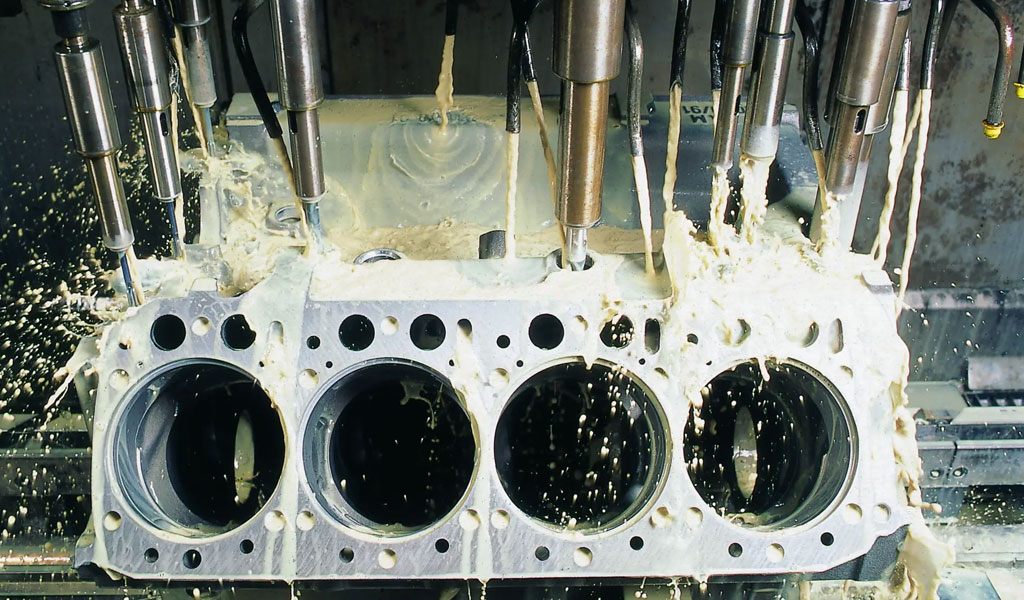

CNC machining is a manufacturing process that utilizes computer-controlled machines to create intricate and precise parts from a variety of materials such as metals, plastics, and more.

In contract CNC machining, a company or individual (the “client” or “customer”) partners with a third-party machining company (the “contract manufacturer” or “machine shop”) to produce the desired parts according to specified designs, dimensions, and tolerances. The client provides the machine shop with the design files, often in formats like Computer-Aided Design (CAD) models, which are then translated into machine instructions by the CNC equipment.Contract CNC machining offers several advantages to clients:

- Expertise: CNC machine shops specialize in machining processes and have experienced personnel who are well-versed in the intricacies of CNC programming, tool selection, and material handling.

- Precision: CNC machines can achieve extremely high levels of accuracy and repeatability, ensuring that the manufactured parts meet the required specifications.

- Cost-effectiveness: Outsourcing machining to a contract manufacturer can be more cost-effective than investing in the machinery, personnel, and facilities required for in-house manufacturing.

- Flexibility: Contract machining companies often have a wide range of CNC equipment, allowing them to handle various part sizes, shapes, and materials.

- Focus on core activities: By outsourcing machining, the client can focus on their core business activities, such as design, marketing, and assembly, while leaving the manufacturing to experts.

- Faster turnaround: Established machine shops are equipped to handle production runs efficiently, potentially reducing lead times for the production of parts.

- Scalability: Contract machining can accommodate varying production quantities, from small prototype runs to large-scale production orders.

- Reduced risk: The machine shop’s expertise and quality control processes can mitigate the risks associated with errors or production defects.

It’s important for clients to select a reputable and capable contract machining partner, as the quality of the manufactured parts and the reliability of the service provider can significantly impact the success of the overall manufacturing process. Effective communication, clear design specifications, and a well-defined contractual agreement are essential for a successful contract CNC machining relationship.

Contract CNC Machining Service

At Be-Cu prototype, we understand the critical role that precision manufacturing plays in today’s competitive market. Our state-of-the-art CNC machining facility is equipped with the latest technology and staffed by a team of highly skilled engineers and machinists who are committed to delivering excellence in every project we undertake.We specialize in producing intricate parts with tight tolerances. Our advanced CNC equipment ensures that every component is manufactured to your exact specifications.

Whether you require prototyping, small batch production, or large-scale manufacturing, we have the capacity to meet your needs efficiently and effectively.Our expertise extends to a wide range of materials, including metals, plastics, and composites. This enables us to accommodate diverse industry requirements.We understand the importance of deadlines.

Our streamlined processes enable us to deliver on time without compromising on quality.We view our clients as partners. Our team is dedicated to collaborating closely with your engineering and design teams to achieve the best possible outcomes.We would welcome the opportunity to discuss how our Contract CNC Machining services can add value to your operations. Please feel free to reach out to us at [email protected] to schedule a meeting or request a quote.

Why Choose Our Contract CNC Machining Service?

- Save time and money for your Contract CNC Machining project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Contract CNC Machining parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Contract CNC Machining Parts & Case Studies

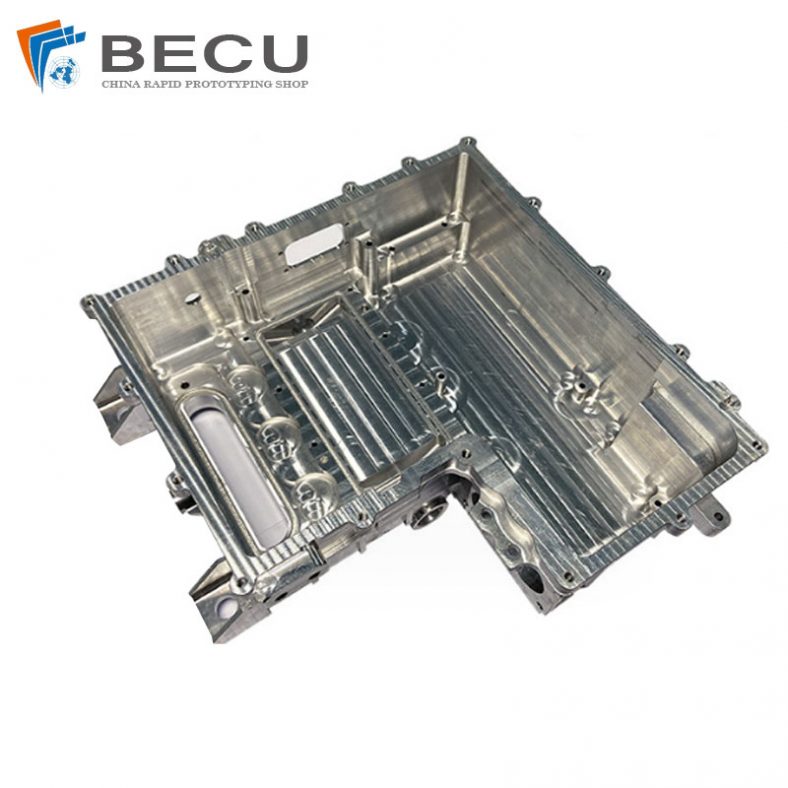

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make rapid prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making cnc machining concept models and precise functional components. Understanding the properties of different material, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on metal and plastic. Be-cu prototyping company provides a range of solutions for the machining of spare parts.

-

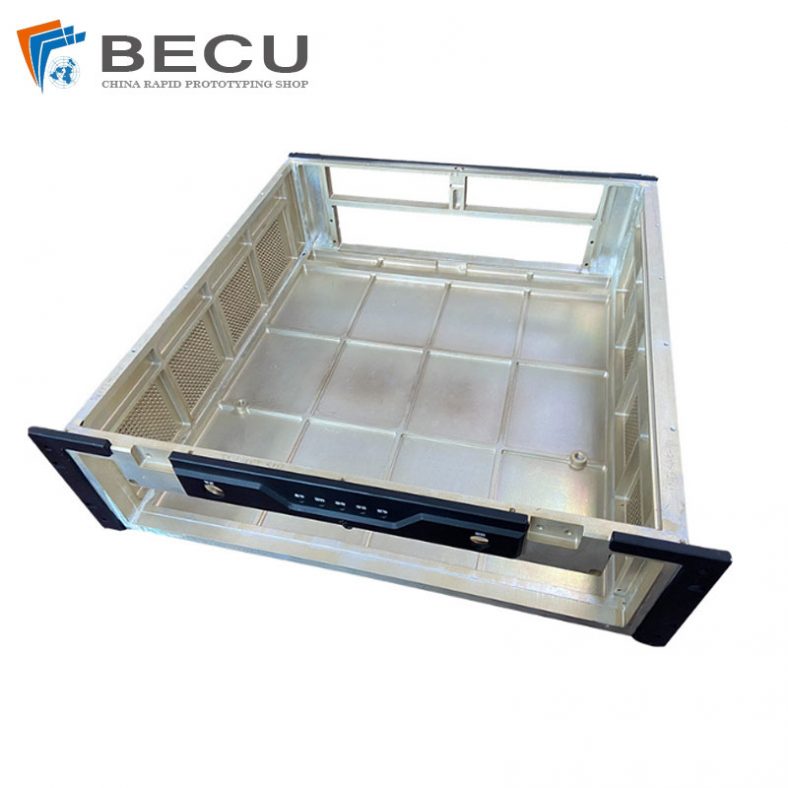

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

CNC 6063 Aluminum Automotive Motor End Cover

-

CNC Machining Gas Stove Bottom Joint

-

CNC Turning 6063 Bicycle Tightening Disc

-

Custom Chinese Antique Feng Shui Compass Via Cnc Machining

-

Cnc Machining Aluminum Alloy 6063 Motor Generator Spare Parts

-

Custom CNC Machining High-Altitude Fall Protection Equipment Accessories

-

Precision Machining 6063 Aluminum Alloy 3D Printer Parts

-

Five-Axis Precision Cnc Milling Machining IOT Robotic Parts

-

Aluminum 6063 Complex Robotic Parts By 5 Axis Cnc Machining

-

CNC Machined Rotary Head Aluminum Parts

-

Turning And Milling Of Valve Body Parts