What Is Silver Investment Casting

The roots of investment casting trace back to the dawn of human civilization, with archaeological evidence suggesting its presence in various ancient cultures, including those of Mesopotamia, Egypt, and China. The process earned the moniker “lost-wax casting” because the wax patterns used for creating molds were melted away, leaving behind a cavity to be filled with molten metal. Silver investment casting, a specialized variation of this age-old technique, began to emerge as a distinctive practice in the more recent history.

Silver, known for its lustrous beauty, malleability, and conductivity, was a favored choice for artists and craftsmen in ancient civilizations. The application of silver investment casting can be observed in intricate jewelry, ornate utensils, and religious artifacts. For instance, the exquisite silver jewelry of the Etruscans, a pre-Roman Italian civilization, illustrates the precision and elegance achievable through this casting method. The delicate wax patterns were used to create molds that could capture the finest details of the desired design.

During the Renaissance period, silver investment casting experienced a resurgence in popularity as artistic and technical advancements were made. Artists like Benvenuto Cellini and Giovanni Bernardi were notable for their contributions to the art of silver casting. Their creations included elaborate silver sculptures and intricate goblets, showcasing the intricate and decorative possibilities of silver investment casting.

In the modern era, investment casting has become a critical manufacturing process, with applications in aerospace, automotive, healthcare, and jewelry industries. Silver investment casting, in particular, remains a timeless artistry that bridges the past with the present.

Silver Casting Service – Investment Casting Silver Manufacturer

Be-Cu.com is dedicated to producing high quality silver castings(including silver jewelry manufacturing) via its investment casting process. Be-Cu can manage the entire process from initial prototypes for evaluation, designing and building the tool, producing the silver casting, and finishing, which can include polishing,cnc machining, 3d printing and coating.

Be-Cu has extensive process control for the investment casting process. Lost wax casting is a very detailed process that must be controlled carefully at every step. Process variables are endless including temperature, humidity, viscosity, pressure, speed, flow rates, etc.Be-Cu monitors and controls process variables with PLCs and various control instruments. Be-Cu’s silver casting facility is oriented toward small to medium size castings ranging from 100 grams to 25 pounds, and 0.5 to 20 inches. Typical annual volumes can range from hundreds to thousands of parts with relatively short lead times. We offers its customers a short cycle time for production and delivery.Our team of experts can utilize current product prints or work in tandem with our trusted partners to create a product print for full production casting or rapid prototype.For Be-Cu.com, high-quality silver castings with ISO 9001:2015 quality standards make every possible project a true success. Herein, we present aspirational services, silver castings stability, and affordable prices upon request. Reach us for any inquiries.

Types of Investment Casting Finishes

- High Precision Jewelry CNC Machining

- Polished zinc plating, nickel plating, electroplating, chrome plating

- Anodizing, phosphating, acid treatment, polishing

- Broaching, milling, drilling, tapping

- Surface grinding, sand blasting, powder coating

- Heat treatment

How To Make Silver Cast Rings

Making silver cast rings involves several steps, including designing, carving a wax mold, creating a mold, melting the silver, and casting the ring. Here’s a general outline of the process:

Why Choose BE-CU Investment Casting Factory?

At BE-CU Prototype, we use state-of-the-art technology to ensure the success of every project. Below is just some of the investment casting equipment that we leverage:

- Specialized shell-making equipment

- Highly automated robotic molding machines

- Horizontal vacuum precision furnace

- Vertical vacuum precision furnace

- High-pressure gas quenching vacuum furnace

- Reliable quality assurance equipment

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Silver Investment Castings & Case Studies

You have a complex silver part design, Be-cu prototype Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

How To Cast Silver – Silver Casting Molds Making

Casting silver is a specialized process that requires skill, precision, and attention to detail. It’s commonly done using the investment casting method, also known as lost-wax casting. Here are the steps involved in casting silver:

Design and Pattern Creation

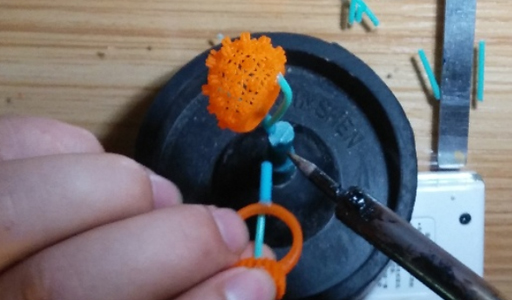

Create a precise wax pattern of the design. This can be done by carving the wax by hand or using a mold to produce an exact replica of your design. Ensure the wax pattern is free of imperfections, as these will be transferred to the final silver piece.

Assembly

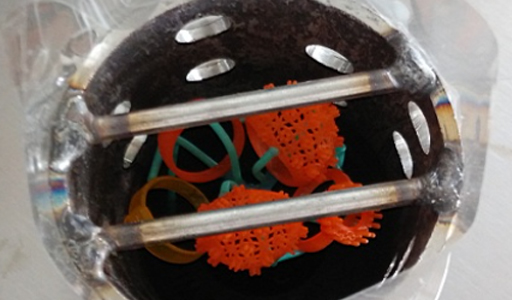

All the wax patterns are attached in a way that allows for efficient metal flow and minimizes the formation of air pockets or bubbles.

Investment (Creating the Mold)

The ceramic shell is typically built up in several layers, allowing each layer to dry before applying the next one. This process continues until the ceramic shell is strong and thick enough to withstand the molten silver.

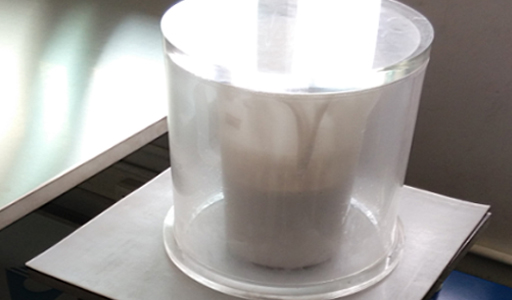

Dewaxing

Firing

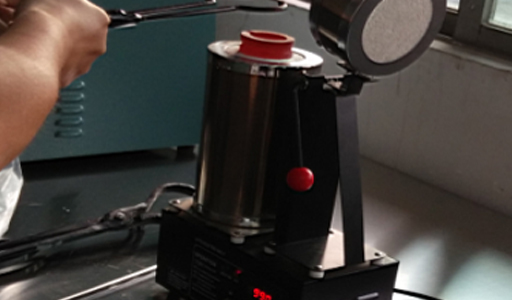

Pouring

Cooling

Breakout

Finishing

Any imperfections, such as sprues or seams, are removed, and the item is meticulously polished and finished to the desired specifications. This can involve sanding, grinding, and buffing to achieve a smooth and shiny surface.

Final Inspection

Depending on the intended use and design, you may choose to plate the silver with other metals like gold or rhodium to enhance its appearance.Engraving or additional decorative work can be performed as needed. Casting silver is a complex and intricate process, requiring expertise and precision at every step. Whether you’re creating exquisite jewelry, artistic sculptures, or specialized industrial components, the art of silver casting continues to captivate and inspire people worldwide.