What Is Steel Investment Casting

Steel is an alloy of iron and other elements, primarily carbon. Because of its high tensile strength and low cost, it is widely used as the main material of all kinds of metalworking processes, such as casting, forging, stamping, machining and fabrication.Steel investment casting, also known as lost wax casting, is a precision casting process used to create complex and intricate steel components with high dimensional accuracy and surface finish. It is a versatile and widely used method in the manufacturing industry.

Steel is a widely chosen material for casting due to its numerous favorable properties and suitability for a range of applications. It offers high tensile strength, hardness, and resistance to wear, making it suitable for components that require robustness and long-term reliability.Steel has good machinability, allowing for ease of post-casting machining operations if required. It can be readily machined, drilled, and tapped to achieve the desired final dimensions and features.Steel is highly weldable, enabling the joining of multiple cast or fabricated steel components through welding processes.These factors contribute to the popularity of steel for casting applications, offering manufacturers a reliable and versatile material choice that meets demanding performance requirements in a wide range of industries.

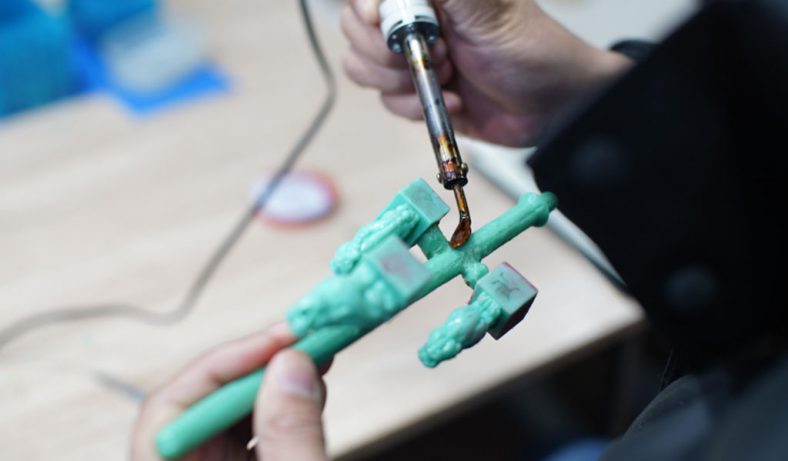

How It Works – Steel Investment Casting Process

Cast steel is a ferrous (iron-based) alloy with a maximum carbon content of approximately 0.75 percent. Steel castings are solid metal objects produced by filling the void within a mold with liquid steel. They are available in many of the same carbon and alloy steels that can be produced as wrought metals. Mechanical properties for cast steel are generally lower than wrought steels with the same chemical composition. Cast steel compensates for that disadvantage with its ability to form complex shapes in few steps.

The Benefits Of Steel Investment Casting

Complex and Intricate Designs

Excellent Dimensional Accuracy

Superior Surface Finish

Versatility of Material Selection

Cost Efficiency

Reduced Material Waste

Consistency and Reproducibility

Design Optimization and Lightweighting

Investment casting enables the integration of multiple components into a single cast, reducing the need for assembly and improving overall part integrity and performance.Steel investment casting finds applications in various industries, including automotive, aerospace, defense, energy, and general engineering, where high-quality and complex components are required.

Steel Investment Casting Service – Steel Lost-Wax Cast Manufacturer

Steel’s malleability and ductility allow for complex and intricate designs to be cast accurately. It can be shaped into a wide variety of forms, including thin walls, intricate details, and complex geometries.Steel Alloy Investment Casing is widely recognized and accepted as a standard cast process in various industries, including automotive, aerospace, construction, and machinery. Its well-established properties and performance make it a trusted choice for critical components.

It is clear that steel investment casting is a highly technical process that requires skill and experience for proper execution. Do you need some casted parts? Be-Cu prototype company is your best partner in providing unbeatable casting services including steel investment casting and die casting services.

Be-Cu boasts a self-owned lost wax casting process and shell molding manufacturing complex with state-of-the-art casting equipment, and an experienced team of engineers, complemented by a professional technical team. It consists of 4 major facilities, 1 investment casting foundry and 3 machining factory which enable us to supply precision steel casting parts with annual capacity of over 20,000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world.

Moreover, with our online quotation platform, you can configure part quantity, material, finishing options, and shipping methods to get the most economical solution for your casting needs. So, start your project now!

Types of Investment Casting Finishes

- High Precision Steel CNC Machining

- Polished zinc plating, nickel plating, electroplating, chrome plating

- Anodizing, phosphating, acid treatment, polishing

- Broaching, milling, drilling, tapping

- Surface grinding, sand blasting, powder coating

- Heat treatment

Steel Lost Wax Casting Material Information

Investment casting is one of the main process that steel is served for. We call this type of investment castings as steel investment casting. Below are the main types of steel investment castings.

Carbon Steel Investment Casting

Alloy Steel Investment Casting

At BE-CU Investment Casting Company, all the steel investment castings are available for production. More important is that we can supply machined investment castings as well if necessary. Pls send us the RFQs if you need such products, we will be pleased to offer you our best prices for reference first.

Why Choose BE-CU Investment Casting Factory?

At BE-CU Prototype, we use state-of-the-art technology to ensure the success of every project. Below is just some of the investment casting equipment that we leverage:

- Specialized shell-making equipment

- Highly automated robotic molding machines

- Horizontal vacuum precision furnace

- Vertical vacuum precision furnace

- High-pressure gas quenching vacuum furnace

- Reliable quality assurance equipment

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Steel Investment Casting Parts & Case Studies

You have a complex part design, Be-cu Lost Wax Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.