Laser Cutting For Mica Sheet

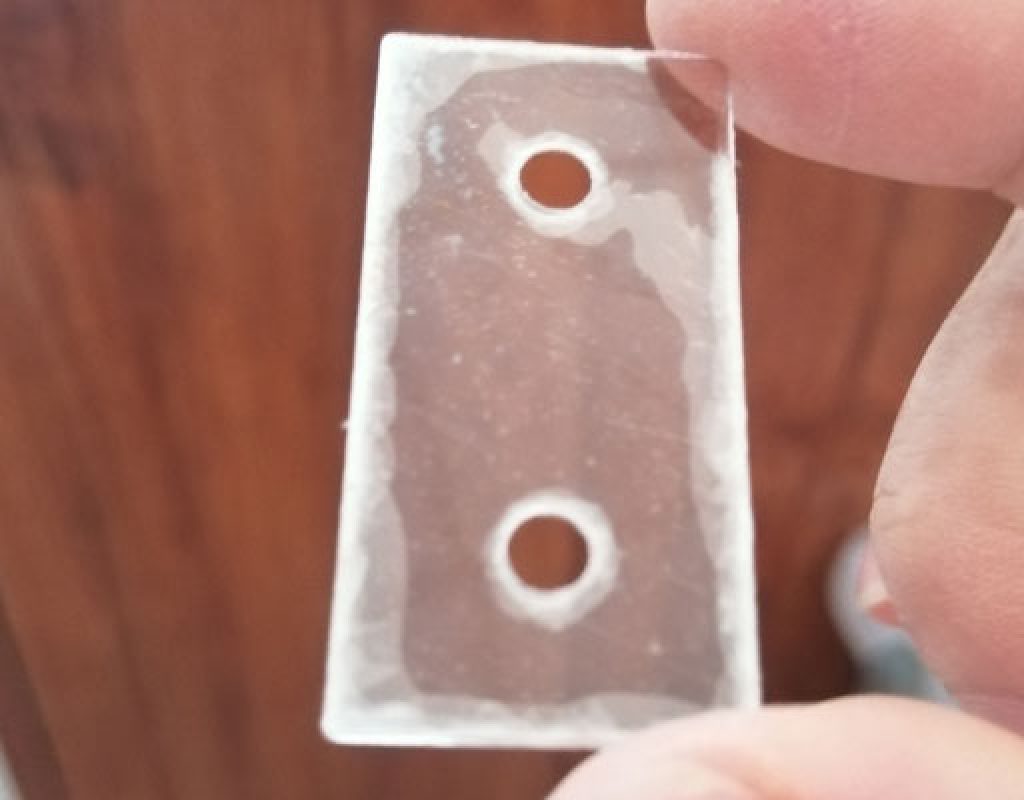

Mica sheets are thin, transparent or translucent layers composed of mica mineral, a naturally occurring mineral with unique physical properties. Mica belongs to a group of sheet silicate minerals and is known for its excellent electrical and thermal insulation properties, heat resistance, flexibility, transparency, and chemical inertness.

Mica sheets are fabricated by compressing or bonding layers of mica minerals together to form flexible or rigid sheets. The most common types of mica used in sheet form are muscovite and phlogopite.

Muscovite mica is generally colorless or light in color, while phlogopite mica tends to have a brown or amber hue due to higher iron content. These sheets are available in various thicknesses and sizes, depending on the intended application.Laser cutting of mica sheets involves the use of a focused laser beam to precisely cut through mica material. Mica is a naturally occurring mineral known for its excellent insulating properties, heat resistance, transparency, and flexibility. It’s commonly used in various industries for electrical insulation, thermal insulation, gasket material, and as a component in electronic devices.

Mica Sheet Laser Cut Service – Custom Mica Plate Laser Cutting Manufacturer

Be-Cu Prototype is now offering complete Laser Mica Sheet Cutting And Precision Cut Service.

Be-Cu.com

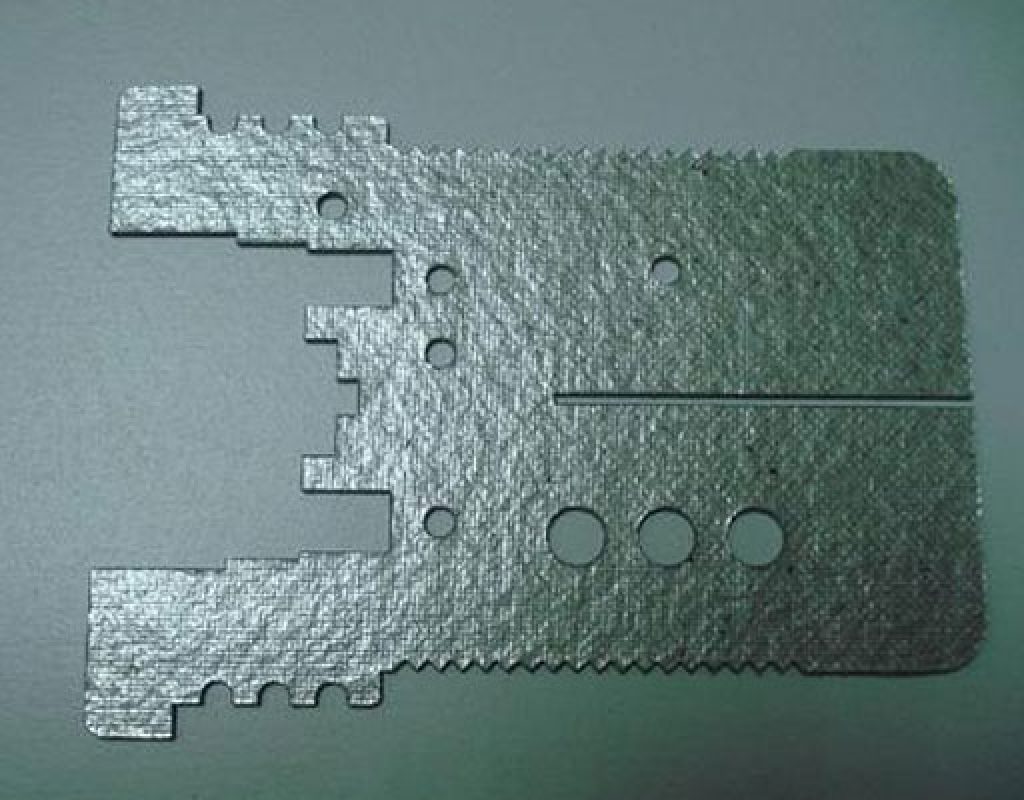

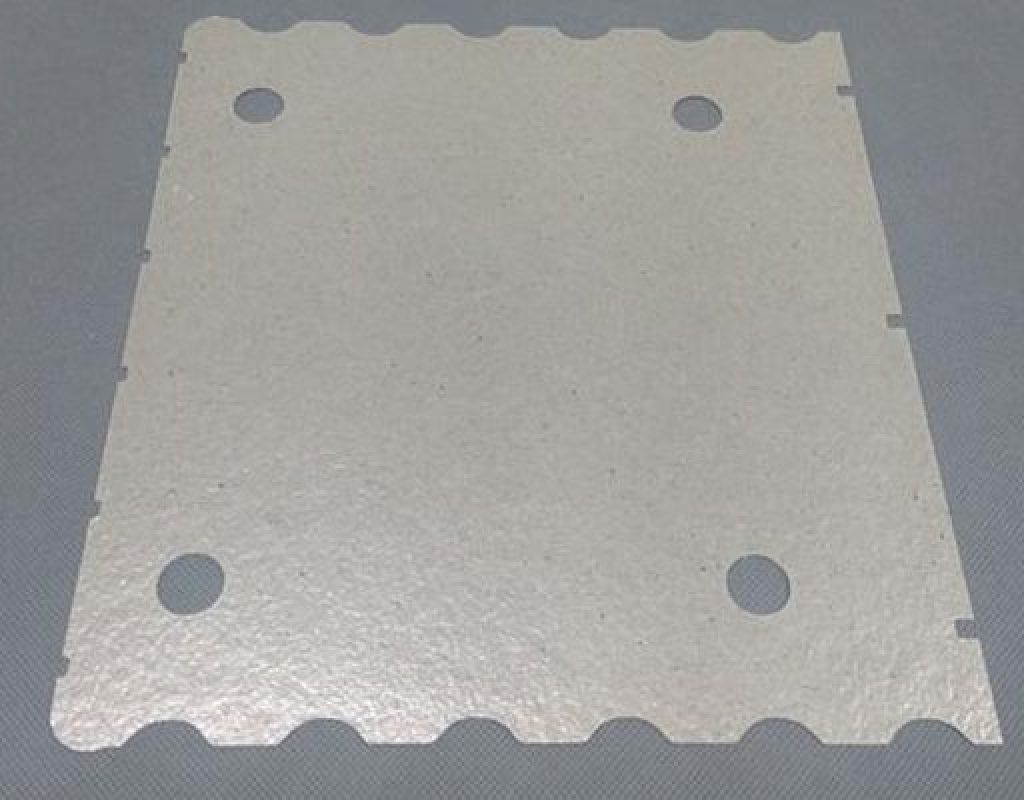

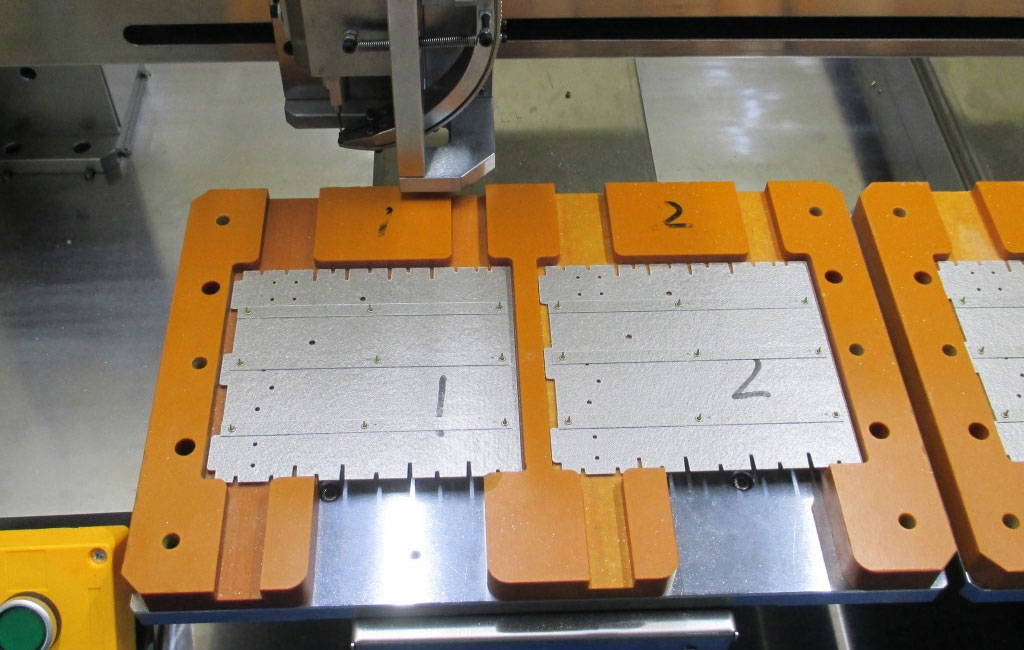

Be-Cu.com provides a wide range of manufacturing capabilities, including Laser cutting of mica sheets and other value-added services for all of your prototyping and production needs.We placed mica sheet on the laser cutting bed. The laser beam follows the pattern outlined in the digital design, precisely cutting through the mica sheet along the specified lines. The intense heat generated by the laser vaporizes or melts away the material along the cutting path.Our Laser cutting mica plate can be die punched up to 1/16″ thick and made to specification beyond 1/16″.

This material can be cut to a fabricated part with CNC, laser and waterjet. Mica plate up to a thickness of 4″ may be cut into fabricated parts with CNC, laser and waterjet.

Mica sheets are valued for their combination of physical properties, making them versatile materials in various industries ranging from electrical and electronics to construction, aerospace, and arts and crafts.

Common Mica Sheet Used in Laser Cut – Mica Sheet Types,Grades,Applications

In laser cutting, various types and grades of mica sheets can be used, depending on the specific application requirements. The choice of mica sheet type depends on factors such as the desired thickness, color, transparency, thermal properties, and intended application. Some common types and grades of mica sheets used in laser cutting include:

Muscovite Mica Sheets

Phlogopite Mica Sheets

Flexible Mica Sheets

Rigid Mica Sheets

Applications of laser-cut mica sheets vary based on the specific type, grade, and properties of the mica. Some common applications include:

Electrical Insulation

Thermal Insulation

Gaskets and Seals

Windows and Viewing Ports

The specific grade and type of mica sheet chosen for laser cutting will depend on the intended use, environmental conditions, temperature requirements, and other application-specific factors. Manufacturers and designers select the most suitable mica grade to ensure optimal performance and reliability in their end products.

Benefits Of Laser Cutting Mica Sheet

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of laser cut materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient Laser Cut factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

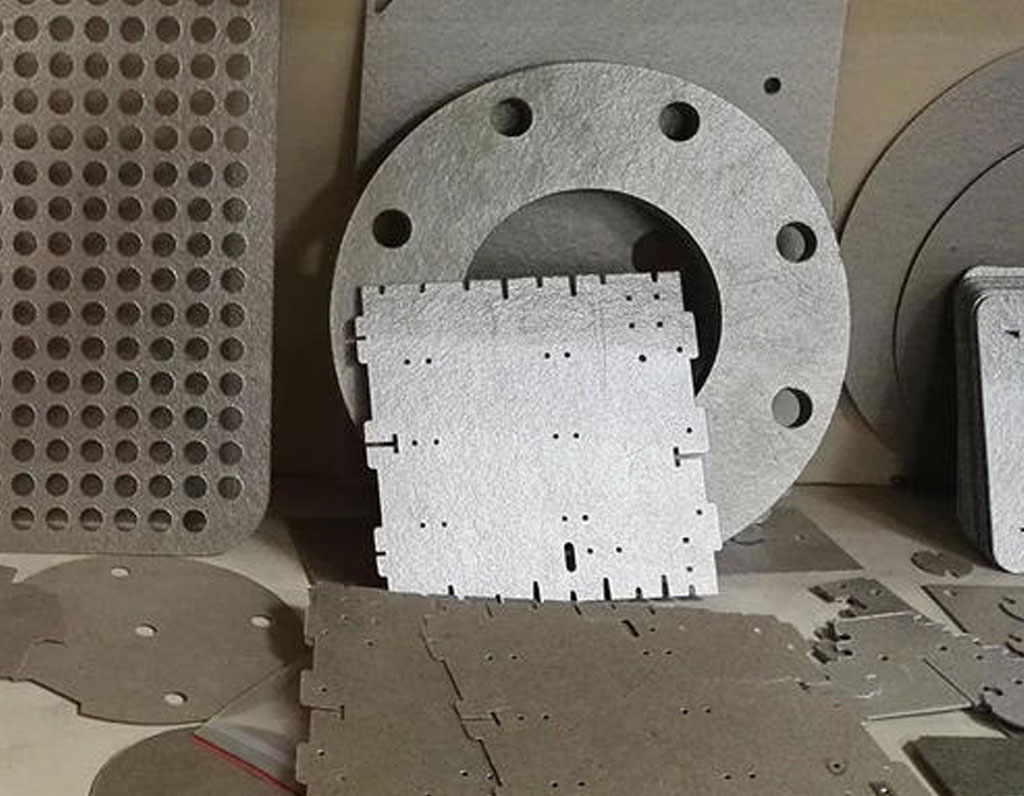

Outstanding Laser Cutting Mica Sheet Case Studies

Using our top of the Mica Sheet laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of Mica Sheet. Using our high speed Mica Sheet laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision Mica Sheet laser cutting prototypes and parts from our valued customers.