Tungsten Cobalt Carbide Punch

- No.: Tungsten Machining

- Color: Custom

- Surface Treatment: Custom

- Product Material: Tungsten Cobalt Carbide

- Proofing Cycle: 7 days(100000 pcs/M)

- Accuracy: 0.005mm

- Hardness: 58-62

- Squareness: 100mm

- Product Category: Mold Parts

- Production Process: Sintering

- Size: According To Customer’s Drawings

High-Quality CNC Machining Tungsten Cobalt Carbide Punch

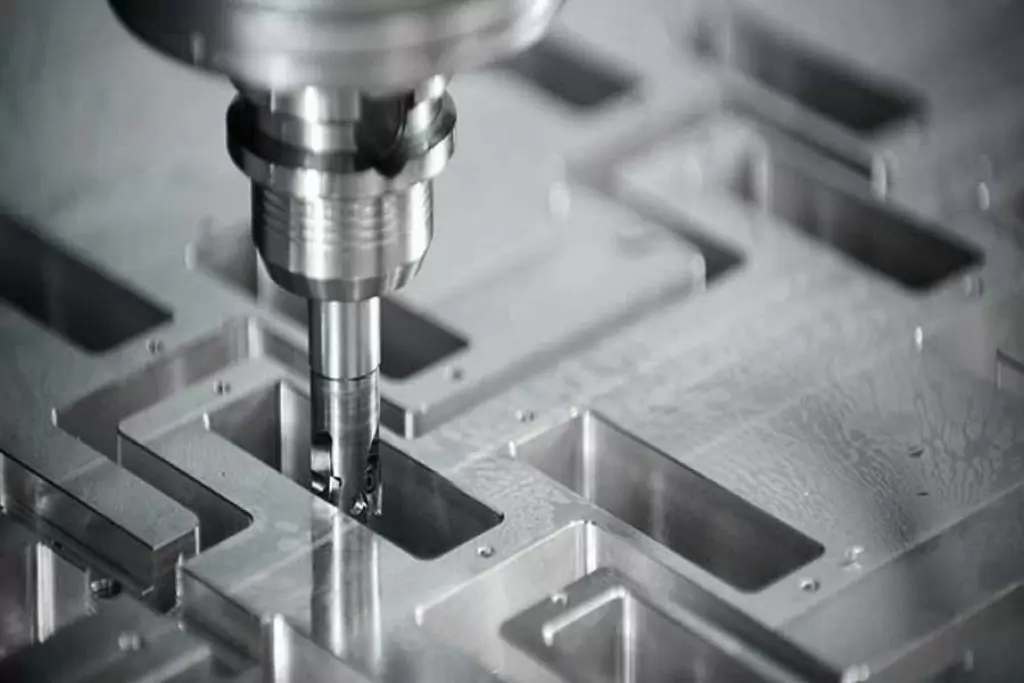

The CNC Machining Tungsten Cobalt Carbide Punch is a high-performance industrial tool designed for precision metalworking applications. This punch is crafted from Tungsten Cobalt Carbide, a unique material known for its exceptional hardness, wear resistance, and toughness. The combination of CNC machining technology and the superior properties of Tungsten Cobalt Carbide ensures that this punch delivers outstanding performance and longevity in the most demanding environments.

Key Features

- Tungsten Cobalt Carbide Material: The punch is manufactured using high-quality Tungsten Cobalt Carbide, a composite material consisting of tungsten carbide particles bonded with a cobalt matrix. This composition imparts extraordinary hardness and durability, making the punch ideal for heavy-duty punching and forming applications.

- Precision CNC Machining: The punch is meticulously crafted using advanced Computer Numerical Control (CNC) machining technology. This process guarantees precise and repeatable results, ensuring each punch conforms to tight tolerances and exact specifications.

- Excellent Wear Resistance: Tungsten Cobalt Carbide’s inherent wear resistance ensures minimal wear and extended tool life even under intense use, reducing downtime and maintenance costs.

- High Strength and Toughness: The unique combination of tungsten carbide and cobalt matrix provides exceptional strength and toughness, allowing the punch to withstand high impact forces without chipping or fracturing.

- Versatile Applications: The CNC Machining Tungsten Cobalt Carbide Punch finds application in various industries, including metal fabrication, stamping, punching, piercing, and blanking processes.

- Surface Finish Options: The punch is available in different surface finish options, such as precision ground or polished, to meet specific application requirements.

Applications

he CNC Machining Tungsten Cobalt Carbide Punch is an excellent choice for use in the following applications:

- Metal stamping and forming

- Sheet metal fabrication

- Precision punching and piercing

- Blank and hole punching

Availability

The CNC Machining Tungsten Cobalt Carbide Punch is available in various standard sizes and can be custom-designed to suit specific customer requirements.

The CNC Machining Tungsten Cobalt Carbide Punch is a premium-grade tool engineered for precision and durability. Its exceptional wear resistance, high strength, and toughness make it the go-to choice for heavy-duty metalworking applications. With superior CNC machining and the unmatched properties of Tungsten Cobalt Carbide, this punch is a reliable and long-lasting solution for industrial punching needs.

The Advantages Of CNC Machining Tungsten Cobalt Carbide Punch

- Extended Tool Life: Due to its outstanding wear resistance, the punch maintains sharpness and accuracy over an extended period, reducing the need for frequent replacements.

- Increased Productivity: The precision CNC machining ensures efficient and consistent performance, leading to enhanced productivity and reduced production lead times.

- Improved Cost-effectiveness: With its prolonged tool life and minimal maintenance needs, the CNC Machining Tungsten Cobalt Carbide Punch offers cost-effective solutions for high-volume manufacturing processes.

Specifications of CNC Machining Tungsten Cobalt Carbide Punch

| Material | Tungsten Cobalt Carbide alloy |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

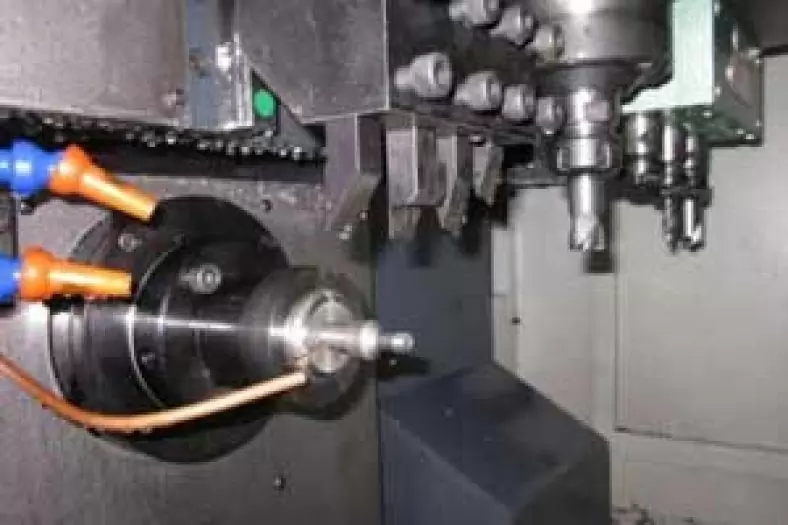

| Main Process | Cnc Turning,EDM Machining,Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Electronic |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]