For many industrial fields that attach great importance to the strength-to-weight ratio, aluminum materials are the preferred choice, and they are more popular due to their corrosion resistance, low density, high ductility and toughness. The use of aluminum often benefits from its good conductivity. In some applications, this conductivity can cause serious problems during machining, especially when using the most sophisticated and cost-effective photochemical etching machining process in the industry today, because it will cause etching A series of major issues such as accuracy and reproducibility.

What Is Aluminum Etching

Photochemical etching has been around as a machining technique for over 50 years, but remains a relatively low-key process today. The practical application of this technology in various manufacturing fields, and the ever-expanding variety of materials, has been the best kept secret in the industry.

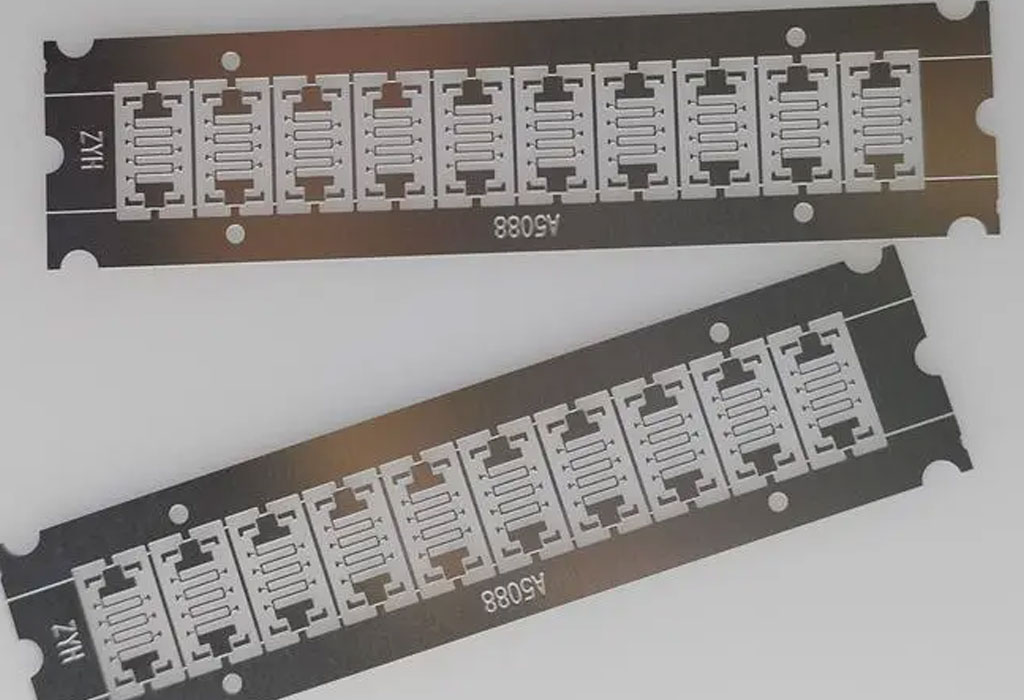

Often misunderstood as a prototyping technique, photochemical etching is a versatile and increasingly sophisticated metalworking technique for producing complex and characteristic metal parts in high volumes.

Photochemical etching uses photoresist and etchant to perform precise chemical processing of selected areas. Its process is characterized by the ability to retain the properties of the material, the parts are burr-free, stress-free, and have a clean appearance without heat-affected zones.

In addition, photochemical etching provides a cost-effective, high-precision and rapid manufacturing process using easily reproducible, low-cost digital processing tools to replace traditional stamping, pressing, punching, laser and water jet cutting processes.

However, for any machining technology to be used in a modern and innovative manufacturing project and environment, it must meet the needs of the industry. Specifically, today’s machining techniques must be able to meet the extremely tight tolerances and machining requirements of more advanced materials that a variety of industrial applications demand.

As a result, companies like Be-cu.com have invested in research and development of photochemical etching technology, spending a lot of time and money to further optimize the processing of aluminum, a material notoriously difficult to process.

Many companies that have used traditional processes to process aluminum will be familiar with some problems, such as reflective properties, which make laser cutting difficult; and aluminum coating peeling off, making stamping impossible.

Precision Aluminum Etching

Aluminum alloy is also a very popular material for various industrial applications due to its corrosion resistance, light weight and high strength. In this respect, it exhibits many of the advantages of titanium steel, and the strength-to-weight ratio is a key advantage of various metals. However, the cost of aluminum is much lower than that of titanium steel. This low cost is not due to the availability and ease of processing of aluminum (it is actually more expensive to extract from bauxite), but because of its recyclability. It is said that no more aluminum ore will need to be dug for 20 years, as the amount already developed is sufficient for use and can be continuously recycled to meet demand.

Aluminum is also much less dense than titanium. Although titanium steel is stronger and more corrosion-resistant than aluminum, it has a lower fatigue limit and is widely used in various aerospace components, as well as in the fields of automobiles, transportation and construction.

Crucially, aluminum’s low density, combined with other properties such as its excellent thermal and electrical conductivity, make it a material of choice for cables and heat exchangers.But when processing this metal, this characteristic also becomes the only Achilles’ heel. For example, in a photochemical etching process, aluminum reacts with aggressive chemicals and becomes exothermic, releasing thermal energy. This can have secondary, incidental effects on the efficiency and accuracy of the photochemical etching process.

Thus, the effective use of photochemical etching processes on aluminum is hindered due to the exothermic nature of aluminum. At the same time, since aluminum has corrosion resistance, photochemical corrosion is a processing technology based on selective corrosion.Aluminum is amphoteric and can react with acids or bases. Thus, photochemical processing can be performed with either acidic or alkaline etchants, but challenges exist for both applications.

Strict process control is the key to successful photochemical etching. The highly exothermic reaction of aluminum during etching can sometimes damage optical tools, resulting in rougher etching. In fact, the exothermic reaction causes the resist to be drawn away from the aluminum sheet, and the etchant seeps out from under the resist, affecting the etching effect, resulting in a rough, jagged, grainy etch edge, far from what photochemical etching processes typically have Smooth, straight etched profile.

Some studies on effective etching of aluminum focus on the etchant used, others on temperature control, and more on cleaning and preparing the metal.

Due to the huge demand for aluminum applications in all walks of life, coupled with the reproducible and consistent machining requirements, and the overcoming of these challenges has been highlighted in the laser cutting and drilling process, for this reason, Be-cu company invested in aluminum processing Equipment for improving the bonding of etch resists to aluminum.

Aluminum Etching Service – China Aluminum Chemical Etching Company

Looking for reliable, quick-turn Aluminum Chemical Etching services suppliers and Aluminum Chemical Etched product manufacturers? With hundreds of advanced Chemical Etching, our unparalleled design and production capacity capabilities guarantee premier OEM Aluminum Chemical Etched Parts to worldwide customers. At BE-CU – China Top Aluminum Chemical Etching Supplier, you can find comprehensive certified Chemical Etching process in aluminum materials for rapid prototyping and volume production of end-use components or full item.

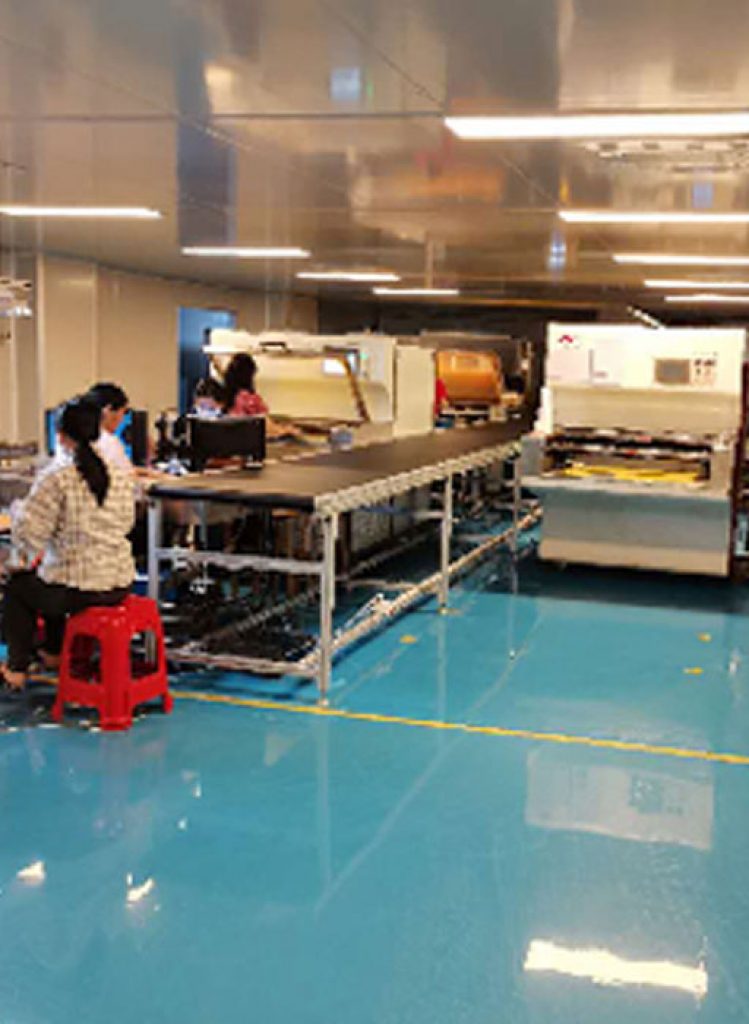

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

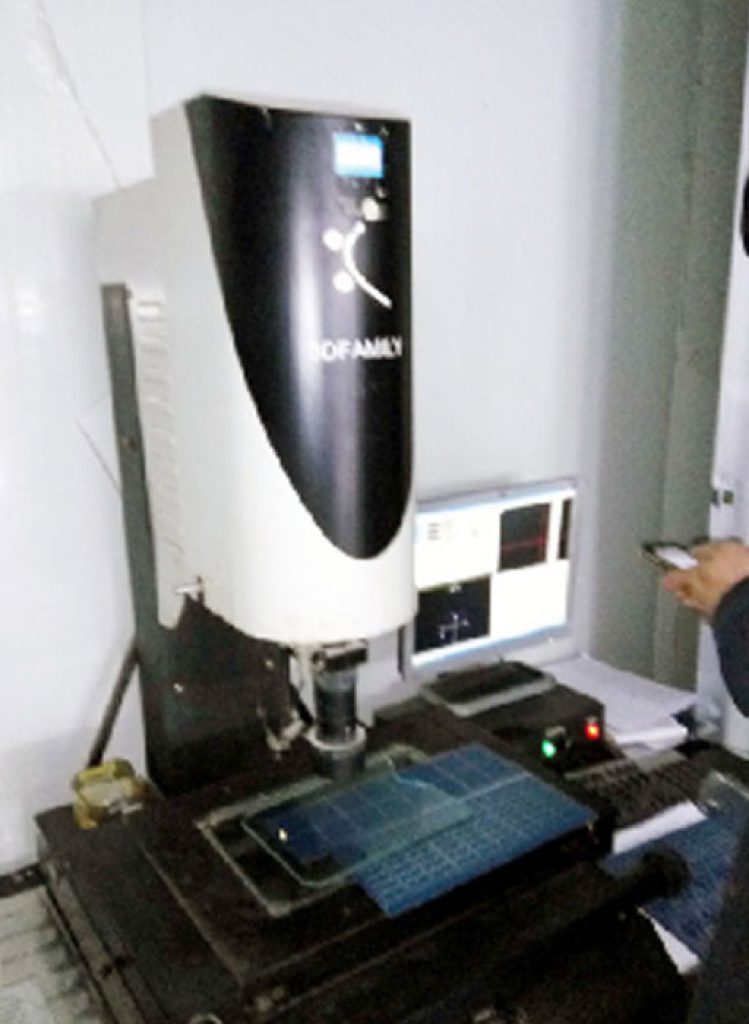

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Aluminum Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Surface Finishing Options for Aluminum Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

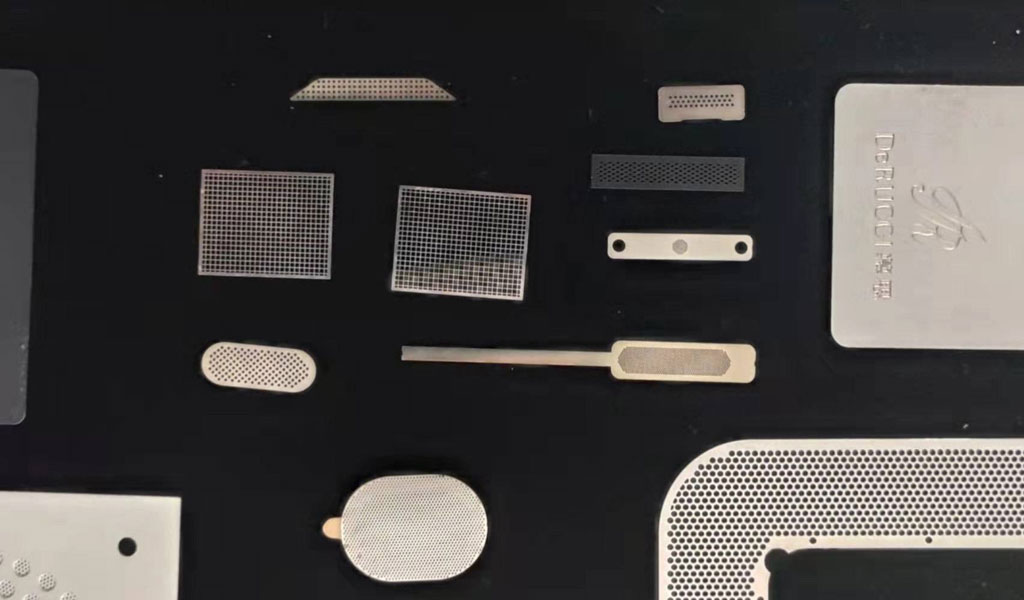

Aluminum Chemical Etching Parts & Case Studies In China

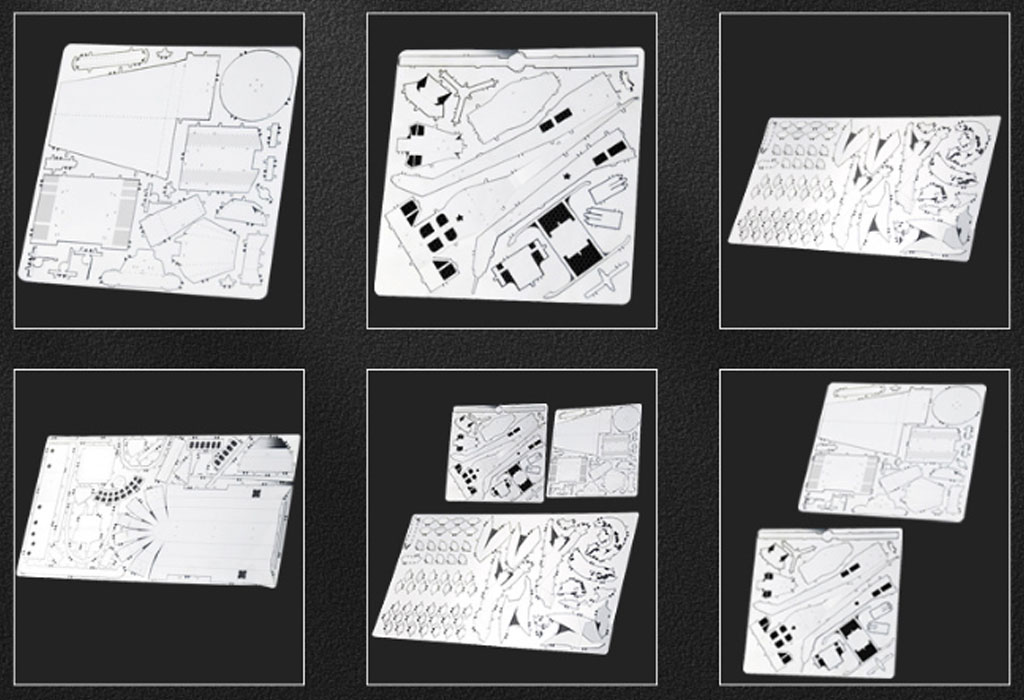

As one of professional Aluminum Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Aluminum material characteristics. So we can offer you the best machining aluminum solution according to your requirements of Aluminum parts and products.

Aluminum Etching For Aerospace Industry

Photochemical etching is a versatile and increasingly sophisticated metalworking technique for the mass production of complex and characteristic technical components.

This adjustment of chemicals, along with the emphasis on other factors such as processing speed adjustment, temperature control, etc., has been satisfactory in Be-cu’s numerous customer projects. All of these factors are inherently interrelated, and one of them can have a negative impact on the other. For example, adjusting the etch rate can cause the etchant to detach. Therefore, process optimization is a balanced act, and its success depends on the accumulation of years of experience in numerous projects and technical knowledge.Through the readjustment of machines, chemicals, and process parameters, Be-cu has successfully participated in countless aluminum photochemical etching projects.

One such example is the etching of an air intake grille for a leading helicopter manufacturer. While this was not at all a large-scale project, the parts were not as rich in features as the ones Be-cu processed (photochemical etching is typically done for high-volume complex parts). However, etching is ideal for processes that tend to create stress in the part. Because it is an aerospace component, weight is a very critical factor, so the customer asked to use aluminum to reduce weight. It was Be-cu’s fine-tuning work on chemicals, processes and machinery that made this project a success.

In another aerospace application, Be-cu has successfully used a similar technology to manufacture various aluminum components for aircraft cabin dehumidifiers.

Be-cu etches channels and precision holes for many of these parts. Since stamping requires the use of 36 different stamping tools, photochemical etching was the preferred manufacturing alternative to this prohibitively expensive process. In addition, stamping cannot achieve the cross-sectional profile required by the flow and temperature profiles. And photochemical etching also means that there is no recasting of layers that machining processes such as electric sparking typically have.