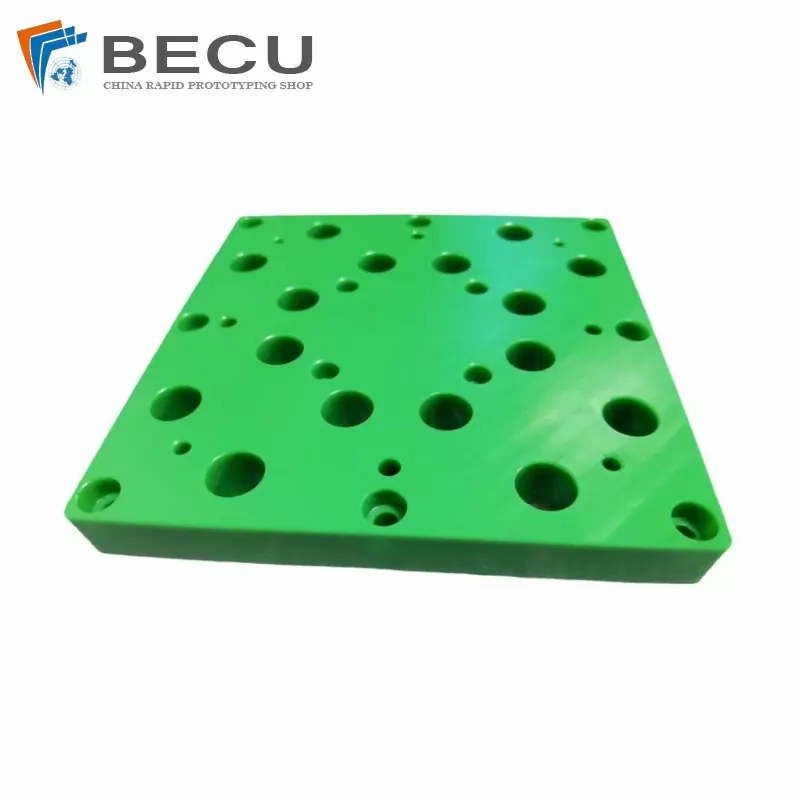

Green Nylon Parts

- Product Name: Nylon Parts

- No+Color:Custom

- Surface Treatment: Oxidation

- Product Material: Plastic

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Jig

- Production Process:Cnc Machining

- Size: According To Customer’s Drawings

High-Quality Precision Cnc Machined Green Nylon Parts

ISO 9001:2015 certified. Custom Precision Parts manufacturer of precision CNC machined parts made from Green Nylon materials also used. Capabilities include boring, routing, sawing, milling, drilling, turning, cutting, tapping and threading. Secondary services such as anodizing, assembly, bending, broaching, centerless grinding, etching, chromating, heat treating, passivating, plating, pressing and welding offered. Prototype and low to high production volume production runs. Serves the aerospace, agriculture, automotive, construction, dental, electrical, marine, medical, oil and gas, recreation, semiconductor and transportation industries.

The Advantages Of Precision Cnc Machined Green Nylon Parts

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Precision Cnc Machined Green Nylon Parts

| Material | Nylon |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | CNC Milling, Swiss Machining, 5 Axis Cnc Machining , CNC Turning |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machinery |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

Nylon is a versatile low-cost plastic, ideal for parts that require high compressive strength and friction resistance, while machining to very tight tolerances. It can be used in place of metal in some applications, allowing for longer-wearing parts that require lower maintenance than its metal counterpart.

Nylon generally is stronger, withstands higher temperatures, and is more cost efficient than PTFE, PEEK.Nylon offers ease of machining and tight tolerances due to its inherent strength, toughness and dimensional stability. Machining Nylon isn’t too different from machining metals as a result of this; pretend you’re machining brass. Unlike metal, though, nylon (like all thermoplastics) will deform if you hold it too tightly as it yields easily. We generally recommend Tungsten Carbide Alloy Tooling. Also, keep the part very cool and support it well. We also suggest non-aromatic, air-based coolants to achieve optimum surface finishes and close tolerances. Coolants have the additional benefit of extending tool life as well.

With the miniaturization of automobiles, the high performance of electronic and electrical equipment, and the acceleration of the lightweight process of mechanical equipment, the demand for nylon will be higher and greater. Nylon has now become the highest quality material for CNC machining instead of metal. As one of the best CNC processing manufacturers in China, Be-cu.com provides high-quality nylon CNC processing services and provides technical assistance for your product lightweight.