Etching Molybdenum (Moly) Plate – Molybdenum Wet Etching

Molybdenum plate is very hard, yet also ductile, possessing toughness superior to tungsten. It exhibits a high elastic modulus, while tungsten and tantalum only boast high melting points. Molybdenum plate finds utility in many specialty steels. Some common applications include molybdenum electrodes, vacuum furnace applications, nuclear energy, missile components, and aircraft parts. Thicknesses ranging from 0.090 inches to 3 inches are categorized as molybdenum plate. Molybdenum plate is extensively used in mold and part furnace construction, as well as component manufacturing in the electronics and semiconductor industries.

Organosilicon molybdenum plate has been scrutinized utilizing a silicon source Si2Cl6 and the conditions of siliconization, along with some of its properties.The siliconized molybdenum plate first deposits siliconized molybdenum, such as 4 MoSi2, initially at a thickness of 6 microns (after 10 minutes), followed by a consolidating storage, forming a uniform layer of MoSi2 on the molybdenum plate after 30 minutes.

The weight of the anodically dissolved organosilicon plate increases twofold in 0.2 M sulfuric acid, reducing the thickness of the MoSi2 layer. Corrosion by seawater and sea sand, as well as wear on the organosilicon molybdenum plate, increases resistance, consequently raising the siliconization temperature and the flow rate of Si2Cl6.

Molybdenum etching represents a culmination of precision engineering and chemical innovation. Over the years, researchers and engineers have refined etching methodologies to achieve unprecedented levels of precision and control. Traditional etching techniques, such as wet etching, have paved the way for more advanced processes like dry etching and plasma etching, enabling precise manipulation of Molybdenum surfaces with minimal material wastage.

The Properties Of Molybdenum

Molybdenum exhibits good strength and stiffness at elevated temperatures, which makes it useful in high-temperature applications.It has a high tensile strength and is relatively ductile, allowing it to be formed into various shapes and sizes.

Physical Properties Of Molybdenum

- Molybdenum has a silvery-white metallic appearance.

- It has a high melting point of 2,623 degrees Celsius (4,753 degrees Fahrenheit), making it one of the refractory metals.

- Molybdenum has a density of 10.22 grams per cubic centimeter, making it a relatively dense metal.

- It has a relatively high boiling point of 4,639 degrees Celsius (8,382 degrees Fahrenheit).

Chemical Properties Of Molybdenum

- Molybdenum is quite resistant to corrosion, and it does not react with oxygen or water at room temperature. However, it will tarnish when exposed to air at higher temperatures.

- It is a moderately reactive metal, and it reacts with acids to form molybdenum salts.

- Molybdenum is also capable of forming various compounds with different oxidation states, ranging from -II to +VI.

Molybdenum Etching Service – Molybdenum Wet Etching Company

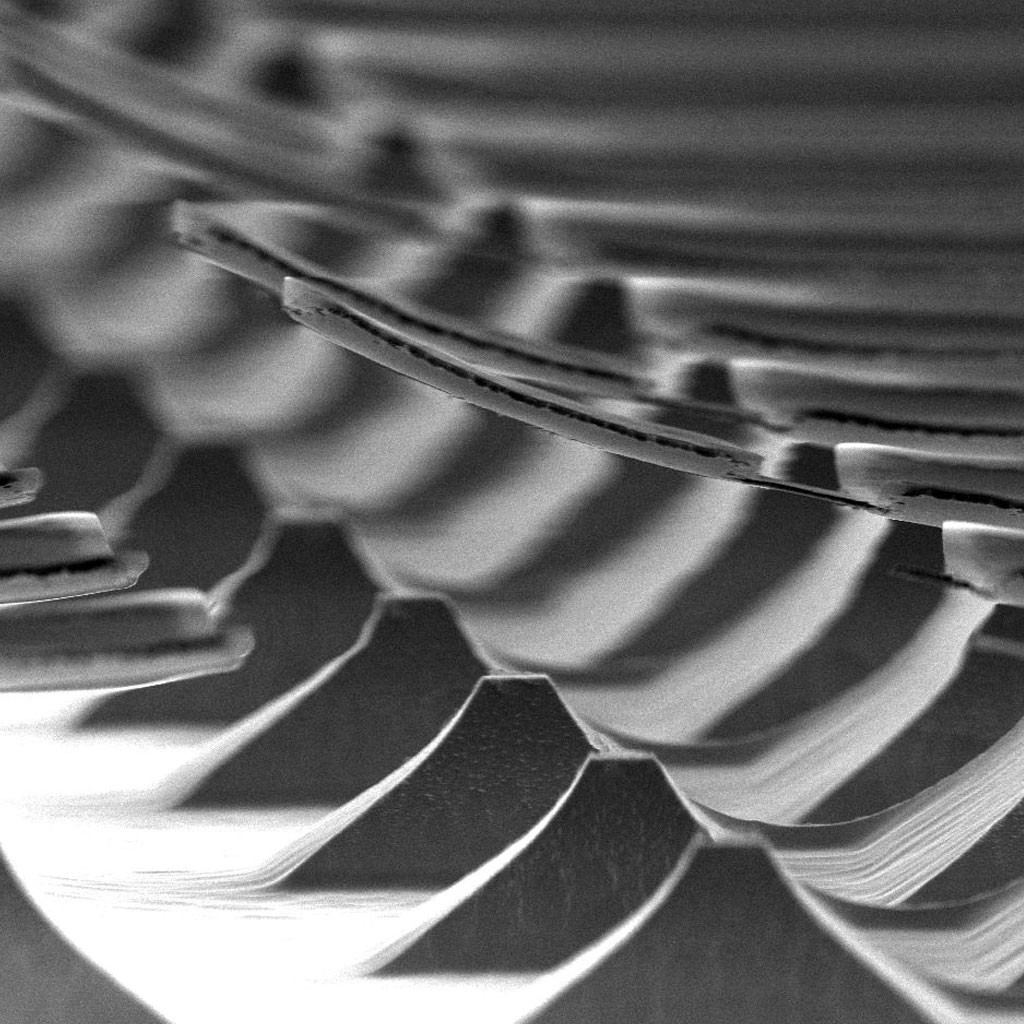

BE-CU etching company applies wet chemical etching techniques to create structures in molybdenum and alloys sheets. The wet etching custom through the metal with high precision, creating clean edges and intricate designs without the need for additional finishing. For molybdenum and alloys, hydrofluoric acid (HF) is used as an etchant, which produces an isotropic etch profile. This makes it ideal for producing complex shapes and patterns that would be difficult to achieve using other methods. Molybdenum exists in various forms and alloys, each designed to suit specific industrial demands. Some common precision etching material types include:

- Pure Molybdenum: Known for its high strength and heat resistance, pure Molybdenum is often used in high-temperature applications such as aerospace and defense.

- Molybdenum-Tungsten (Mo-W): This alloy combines the strength and thermal conductivity of Molybdenum with the excellent mechanical properties of Tungsten, making it ideal for electrical and electronic components.

- Molybdenum-Rhenium (Mo-Re): The addition of Rhenium enhances Molybdenum’s ductility and high-temperature performance, making it suitable for applications in aerospace propulsion systems.

- Molybdenum-Tungsten(MoCu): Molybdenum-copper is a composite material consisting of molybdenum and copper. It possesses properties similar to tungsten copper and offers adjustable coefficients of thermal expansion and thermal conductivity. However, molybdenum-copper has a lower density compared to tungsten-copper, making it more suitable for aerospace and other applications. This product exhibits high purity, uniform structure, and excellent performance.

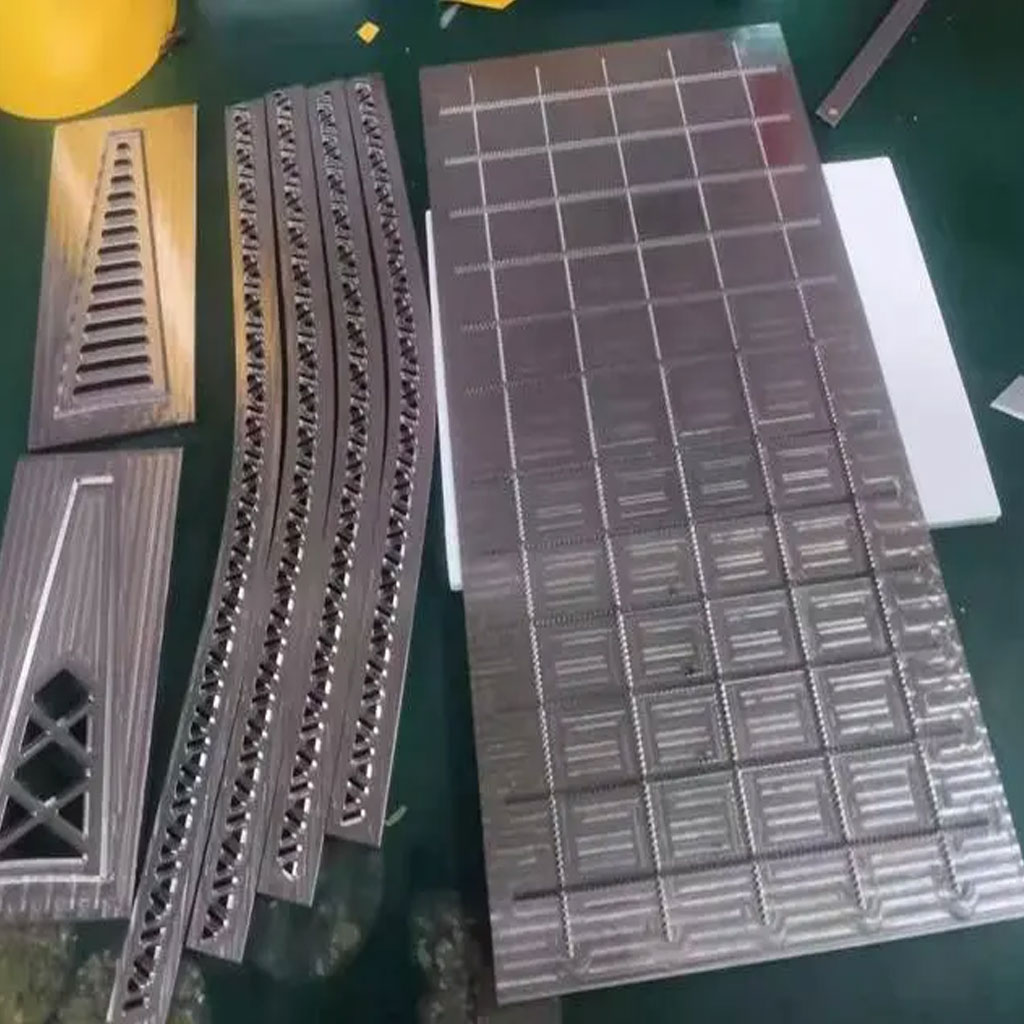

In addition to etching molybdenum and alloys, we offers the etching of various thin film metals such as Au, Cr, Cu, Ni, Ti and the etching of non-conductors such as oxide and nitride.Our wet etching line can handle thin, delicate sheets as well as thick, heavy-duty sheets. We can etching molybdenum plates in various shapes and sizes and customize our molybdenum wet etching services to meet your specific needs.If you need molybdenum wet etching services in china, then we are the perfect company to help you meet your needs.

Benefits Of Our Moly Etching

- Low opening mold fee, tungsten film can be drawn within two hours of etching, allowing for arbitrary changes to external mold shapes, reducing design and development costs.

- Capable of achieving semi-etching and film etching, adding company logos or product numbers of etched molybdenum products.

- Etching technology can guarantee high precision, with accuracy up to +/-0.01mm, meeting the assembly or filtration needs of different components, improving the overall quality and precision of the product, enhancing the added value of the product.

- Metal tungsten sheets with thicknesses ranging from 0.1mm to 0.5mm can all be processed in the same way, meeting the production requirements of different accuracies. Customers can freely choose the thickness of metal tungsten sheet raw materials according to their actual usage needs.

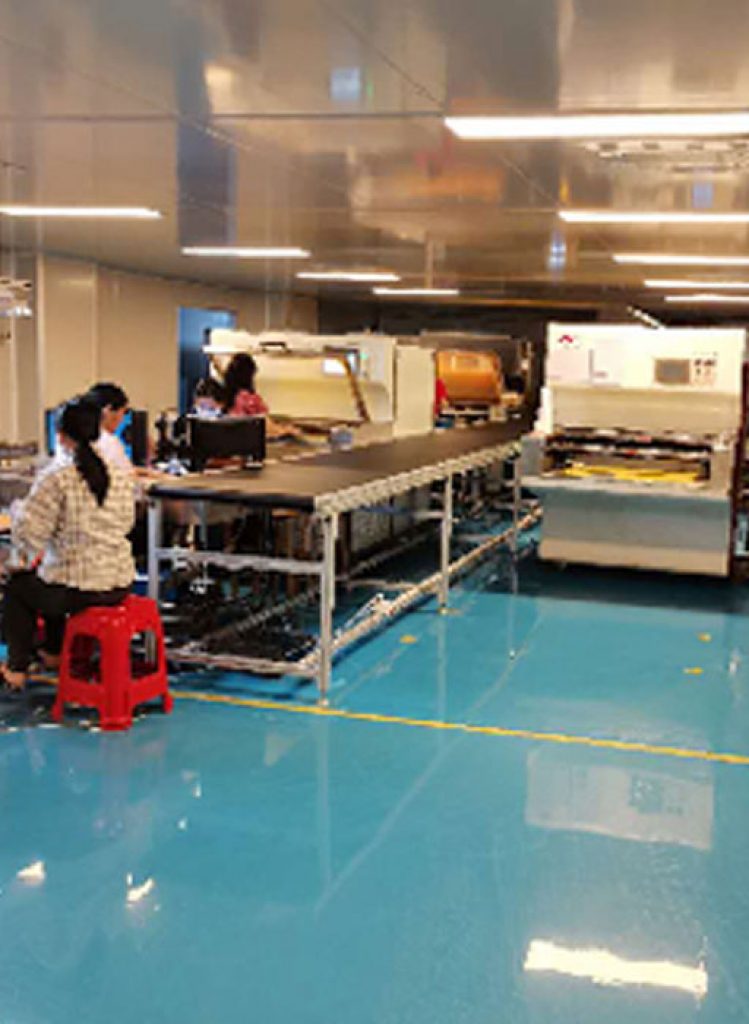

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

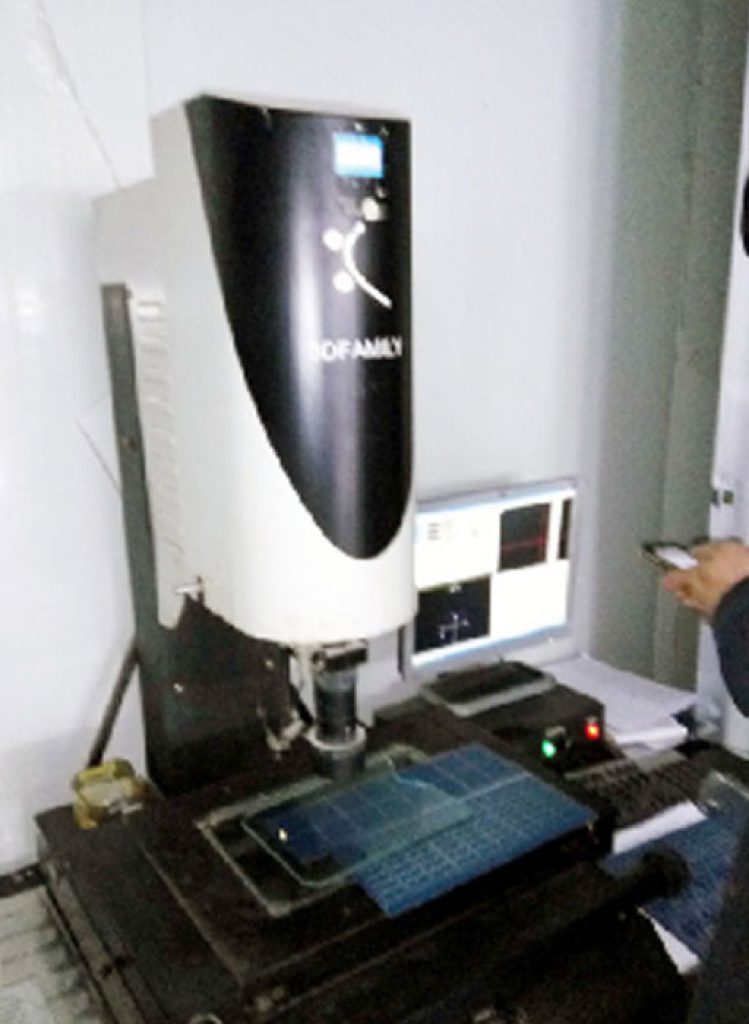

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Molybdenum Chemical And Wet Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Molybdenum Chemical Wet Etching Parts & Case Studies In China

As one of professional Molybdenum Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Molybdenum material characteristics. So we can offer you the best etching Molybdenum solution according to your requirements of Molybdenum parts and products.

Surface Finishing Options for Molybdenum Wet Etching

Parts made using wet etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Online Cooperate With Molybdenum Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.