Simulation Toy Car

- Product name: ABS

- No+Color: Custom

- Application: Custom Toy Car

- Surface treatment: Custom

- Product material: ABS Material

- Proofing cycle: 7 days(100000 pcs/M)

- Manufacturing Factory: BE-CU.com

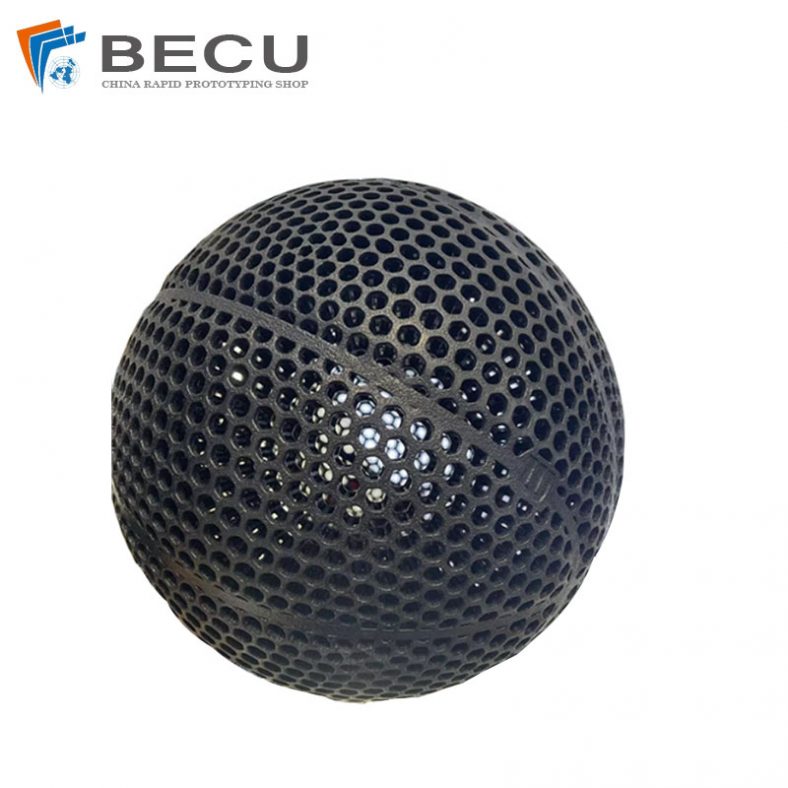

- Production Process: SLA 3D Printing

- Size: Jewelry 3D Printing According To Customer Drawings

High-Quality SLA 3D Printing Simulation Toy Car

- Design your toy car: Use a 3D modeling software such as Tinkercad, Fusion 360, or SolidWorks to create a digital design of your toy car. Consider the size, shape, and design elements you want to incorporate. Make sure the design is suitable for 3D printing and can be printed in separate parts if needed.

- Split the model (if necessary): If your toy car design is too large to be printed as a single piece, you may need to split it into multiple parts that can be assembled later. Ensure that the parts have suitable connection points or slots to fit together.

- Export the model: Once you’re satisfied with the design, export it in a file format compatible with 3D printing, such as STL (Standard Tessellation Language) or OBJ (Object) format. These formats are widely supported by most 3D printers.

- Choose a 3D printing software: To simulate the 3D printing process, you’ll need slicing software. Slicing software takes your 3D model and converts it into a set of instructions that the 3D printer can understand. Popular slicing software options include Ultimaker Cura, PrusaSlicer, or Simplify3D.

- Import and configure the model: Open the slicing software and import your exported model. Adjust the settings according to your preferences, such as layer height, infill density, print speed, and support structures if needed. These settings may vary based on your specific 3D printer and the desired quality of the printed model.

- Simulate the printing process: Most slicing software provides a simulation feature that allows you to preview the printing process before actually printing. This simulation can help identify any potential issues, such as collisions, overhangs, or poor layer adhesion. Run the simulation to ensure everything looks correct.

- Analyze and optimize: After simulating the printing process, carefully inspect the model in the software. Check for any errors, layering issues, or areas that might require additional support. If necessary, make adjustments to your design or printing settings to improve the printability and overall quality.

- Save the sliced file: Once you’re satisfied with the simulation and settings, save the sliced file. This file will contain the instructions required for 3D printing the toy car.

- Load the sliced file onto the 3D printer: Transfer the sliced file to your 3D printer using either an SD card, USB cable, or wireless connection, depending on the printer model.

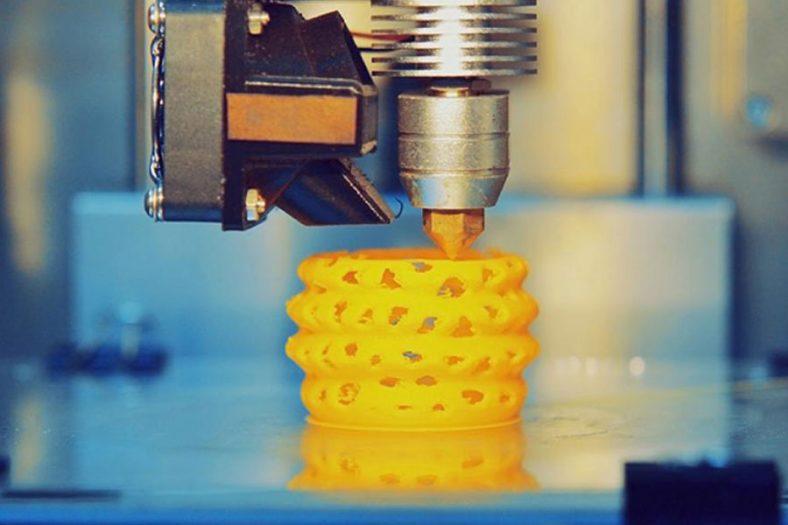

- Start the 3D printing process: Follow the instructions provided by your specific 3D printer to initiate the printing process. Make sure you have the appropriate filament loaded and that the printer is properly calibrated.

- Monitor the print: While the 3D printer is printing your toy car, keep an eye on the progress to ensure everything is going smoothly. Address any issues that may arise, such as filament jams or adhesion problems.

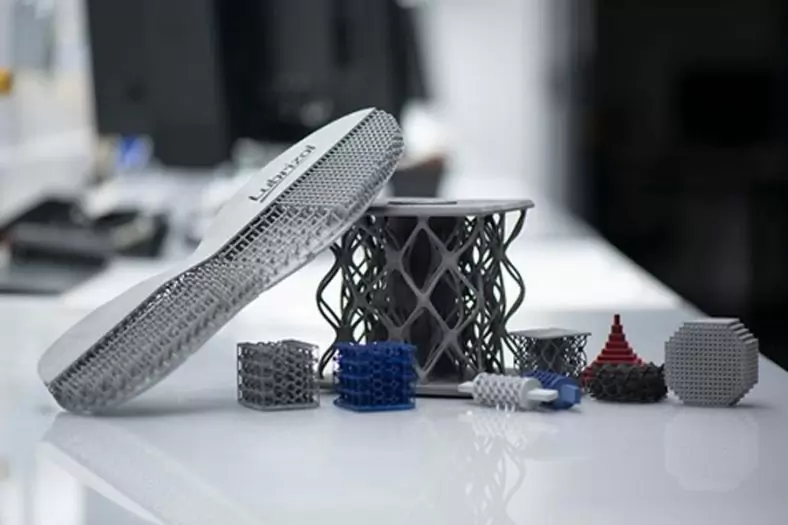

- Post-processing: Once the printing is complete, carefully remove the printed parts from the print bed. If you printed the toy car in multiple parts, assemble them according to your design. You may need to sand or file down any rough edges, add paint or other finishing touches to enhance the appearance of the toy car.

Our online Simulation Toy Car 3D printing service enables you to 3D print your custom Toy Car on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With more than 120 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

Why Choose 3D Printing Simulation Toy Car Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

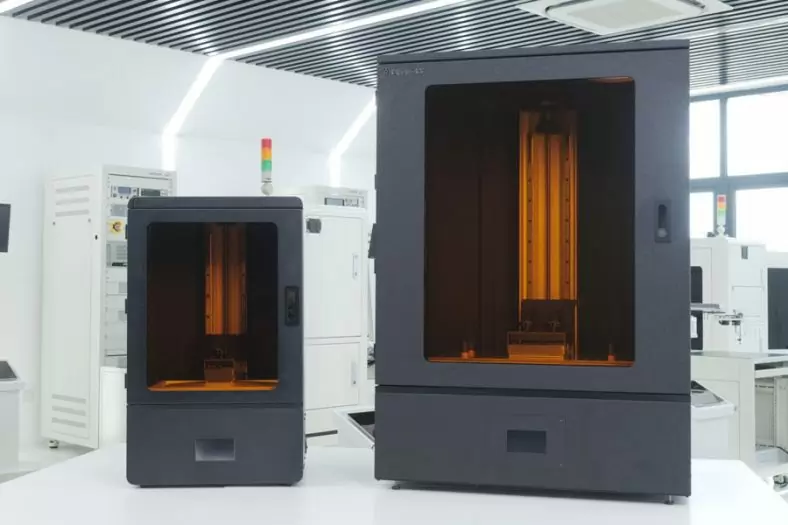

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of 3D Printing Simulation Toy Car

| Item Name | China 3D Printing service |

| Material | thermoplastics, polycarbonate, ASA, nylon12 CF and Ultem resin etc |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.